Welding method

A welding method and post-welding technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult welding process and unsatisfactory welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

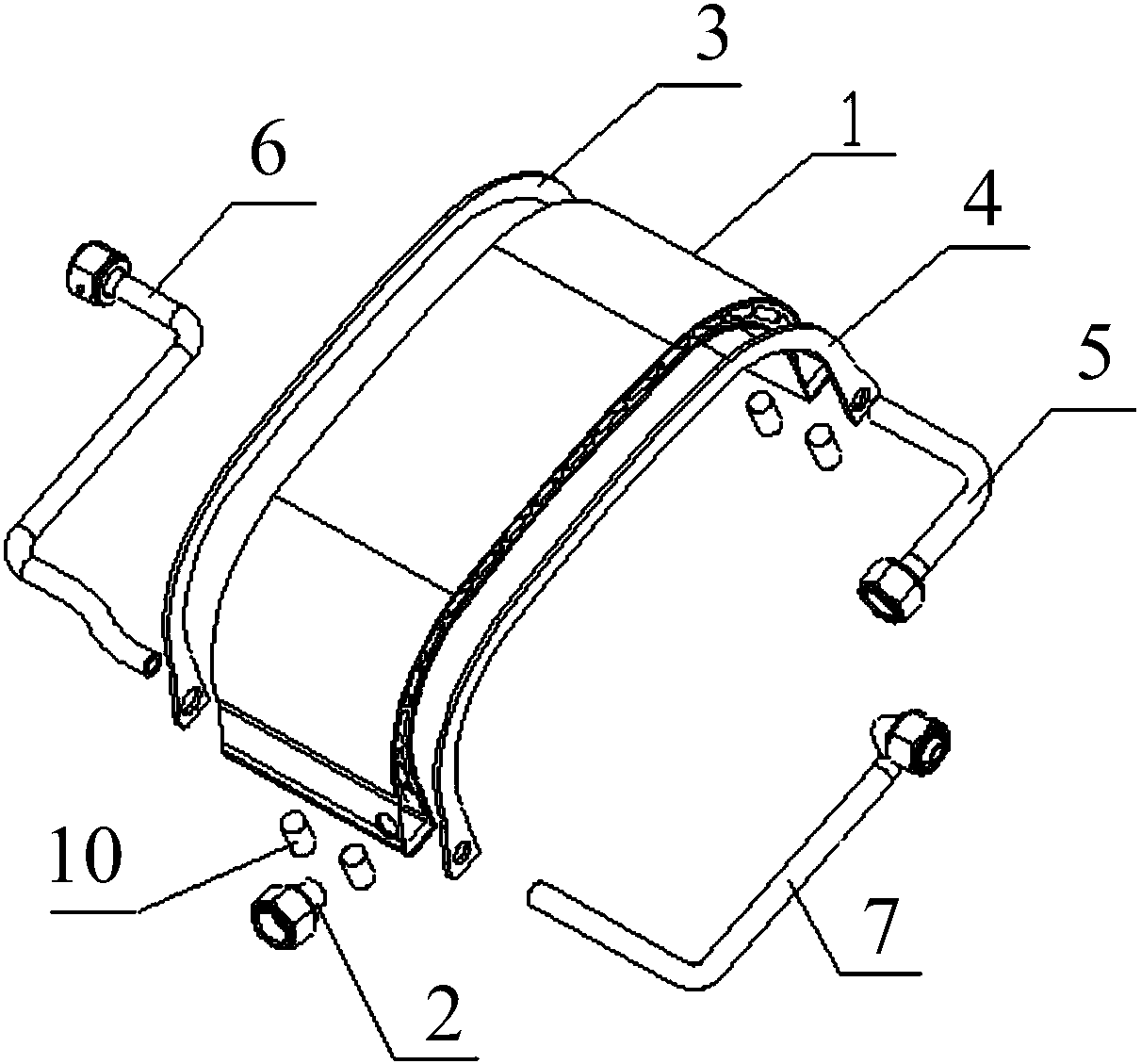

[0041] This embodiment provides a welding method, which is applied to thin-walled liquid ammonia heaters, such as figure 1 As shown, the liquid ammonia heater includes: a heater body 1, a cover plate, a conduit assembly and a mounting stud 2; the cover plate includes: a first cover plate 3 and a second cover plate 4; the conduit assembly includes : the first input conduit assembly 5, the first output conduit assembly 6, the second output conduit assembly 7 and the pressure measuring conduit assembly 8; the heater body 1 is a U-shaped structure, and the cover plate is also a U-shaped structure accordingly .

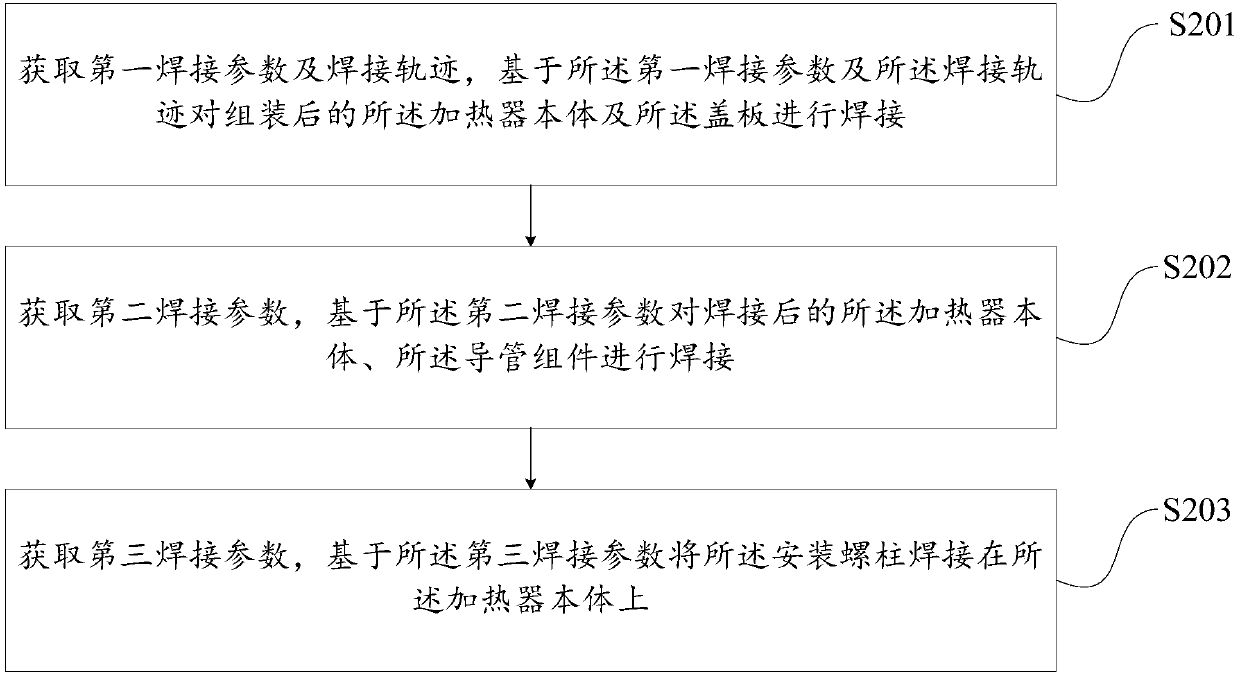

[0042] Such as figure 2 As shown, the method includes:

[0043] S201. Obtain a first welding parameter and a welding track, and weld the assembled heater body and the cover plate based on the first welding parameter and the welding track;

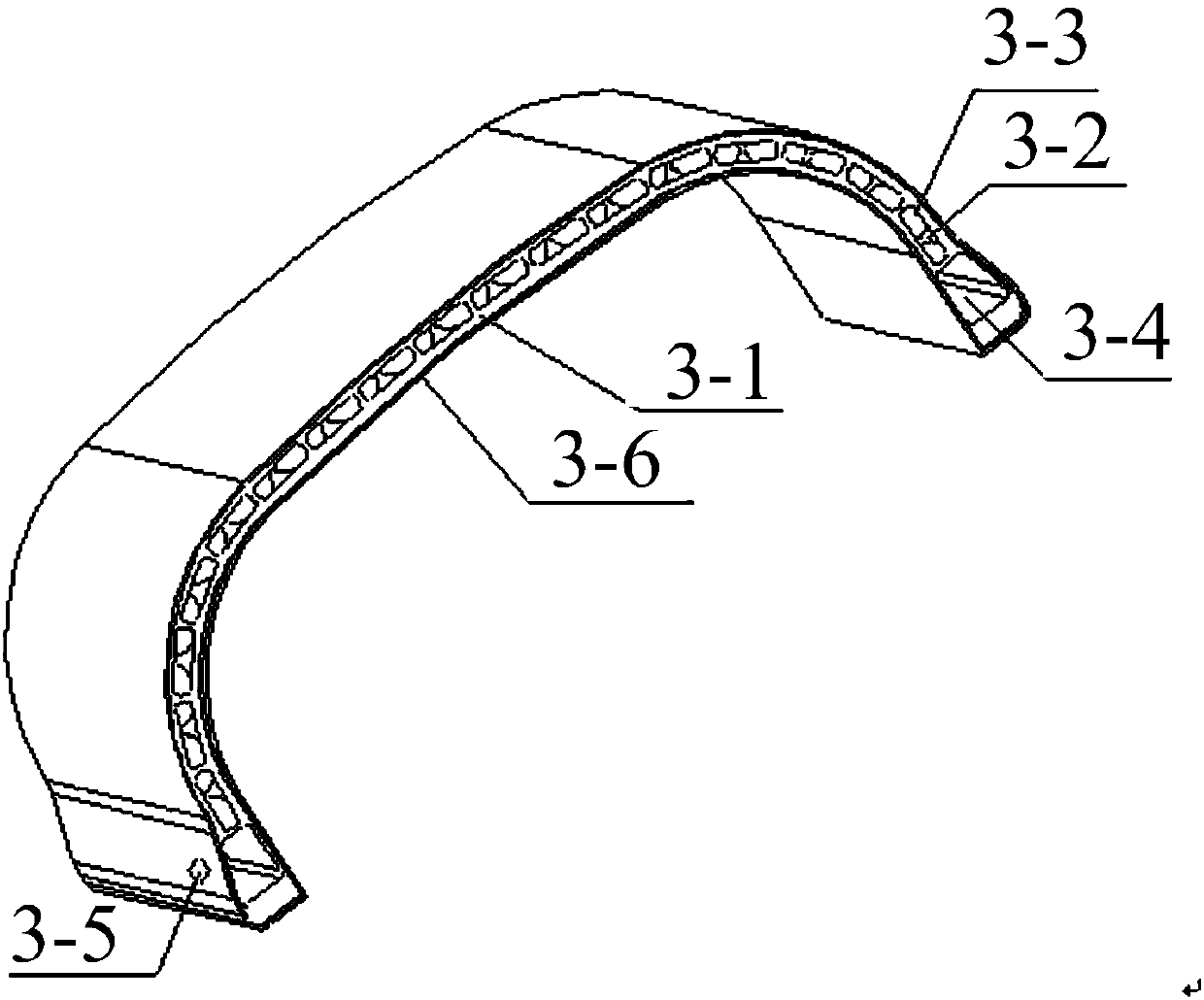

[0044] In this example, see image 3, the heater body is a U-shaped part with a wall thickness of about 10mm and a width of about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com