Material taking and placing mechanism in conveying line system

A conveying line system and conveying line technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as difficult transmission, achieve the effects of improving reliability, ensuring smooth continuity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

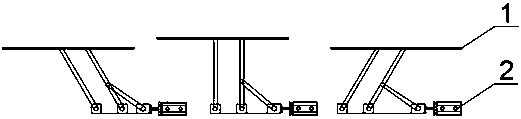

[0016] Such as Figure 1-4 As shown, a material pick-and-place mechanism used in a conveying line system includes a cylinder 2, a slider crank mechanism and a tray 1. The tray 1 is fixedly installed on the upper end of the slider crank mechanism. The slider crank mechanism consists of a slider and a slider. The crank is composed of two parts, the slider and the tray 1 are driven parts, the cylinder 2 is the original moving part, and the cylinder is a single-acting cylinder.

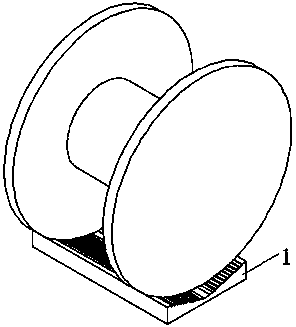

[0017] The shape and size of the tray 1 match the shape of the material, and the upper surface of the tray 1 is provided with several sawtooths.

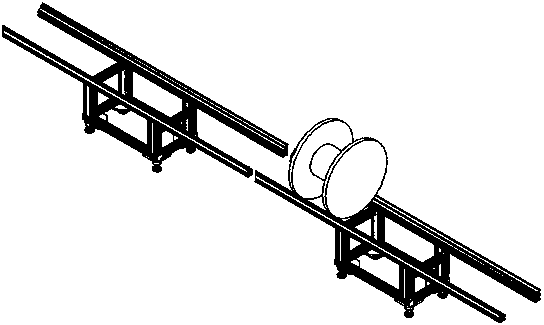

[0018] The conveying system includes two types of fixed conveying line and movable conveying lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com