High-molecular sewage low-temperature separation device

A separation device, polymer technology, applied in water pollutants, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

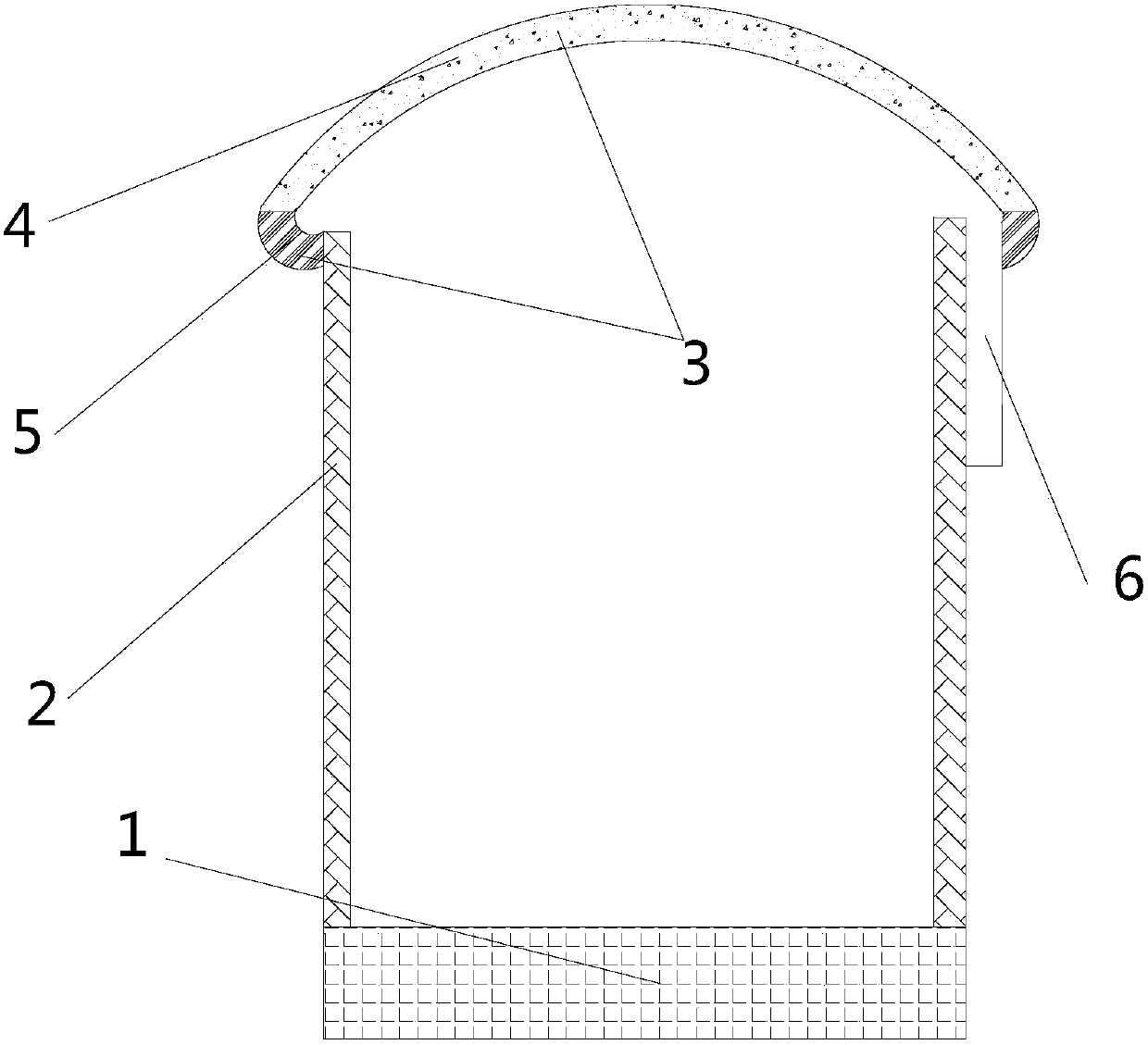

[0012] As shown in the figure, a polymer wastewater low-temperature separation device includes a heating mechanism 1, a tank body 2 and a tank cover 3, the heating mechanism 1 is located at the bottom of the tank body 2, and the tank cover 3 includes a collection part 4 and a tank cover 3. The recovery part 5, the recovery part 5 is an annular depression, the recovery part 5 is located at the edge of the collection part 4; the collection part 5 is hemispherical; the collection part 5 is conical; the collection part The inner surface of 5 is a rough surface; the polymer recovery mechanism 6 is also provided on the annular depression.

[0013] The high-molecular waste water low-temperature separation device of the present invention is used to control the temperature of the heating mechanism at the specified temperature. After a certain period of time, the macromolecules such as pyridine and pyrimidine in the sewage will evaporate from the sewage, so that they can pass through Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com