Automatic sample injector bottle pressing assembly

An automatic sampling and bottle pressing technology, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of sample injection needle deviation, false alarm of bottle missing detection, needle being bent, etc., and achieve lower installation accuracy requirements, The effect of preventing false alarms of missing bottle detection and preventing damage to the sampling needle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

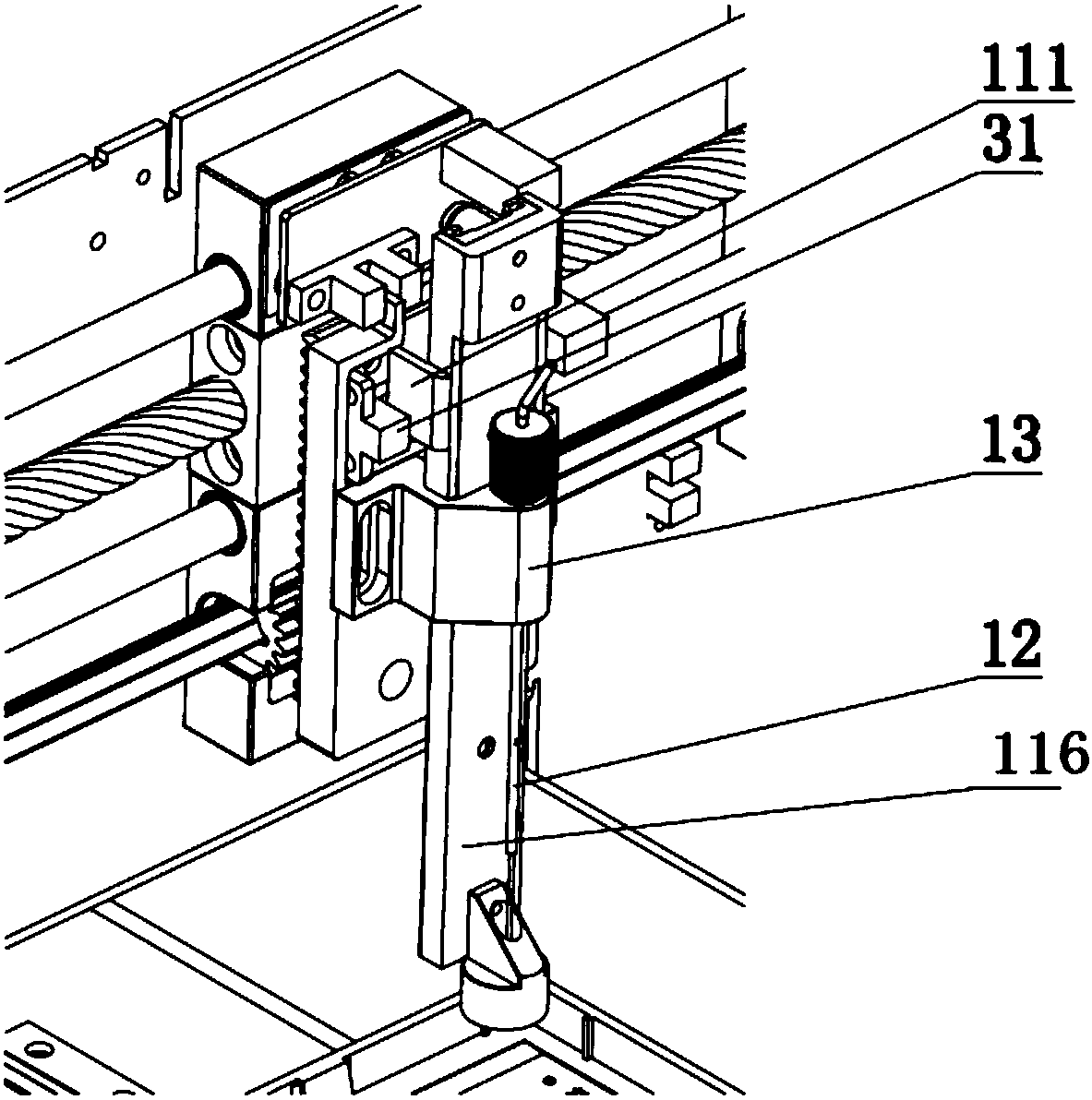

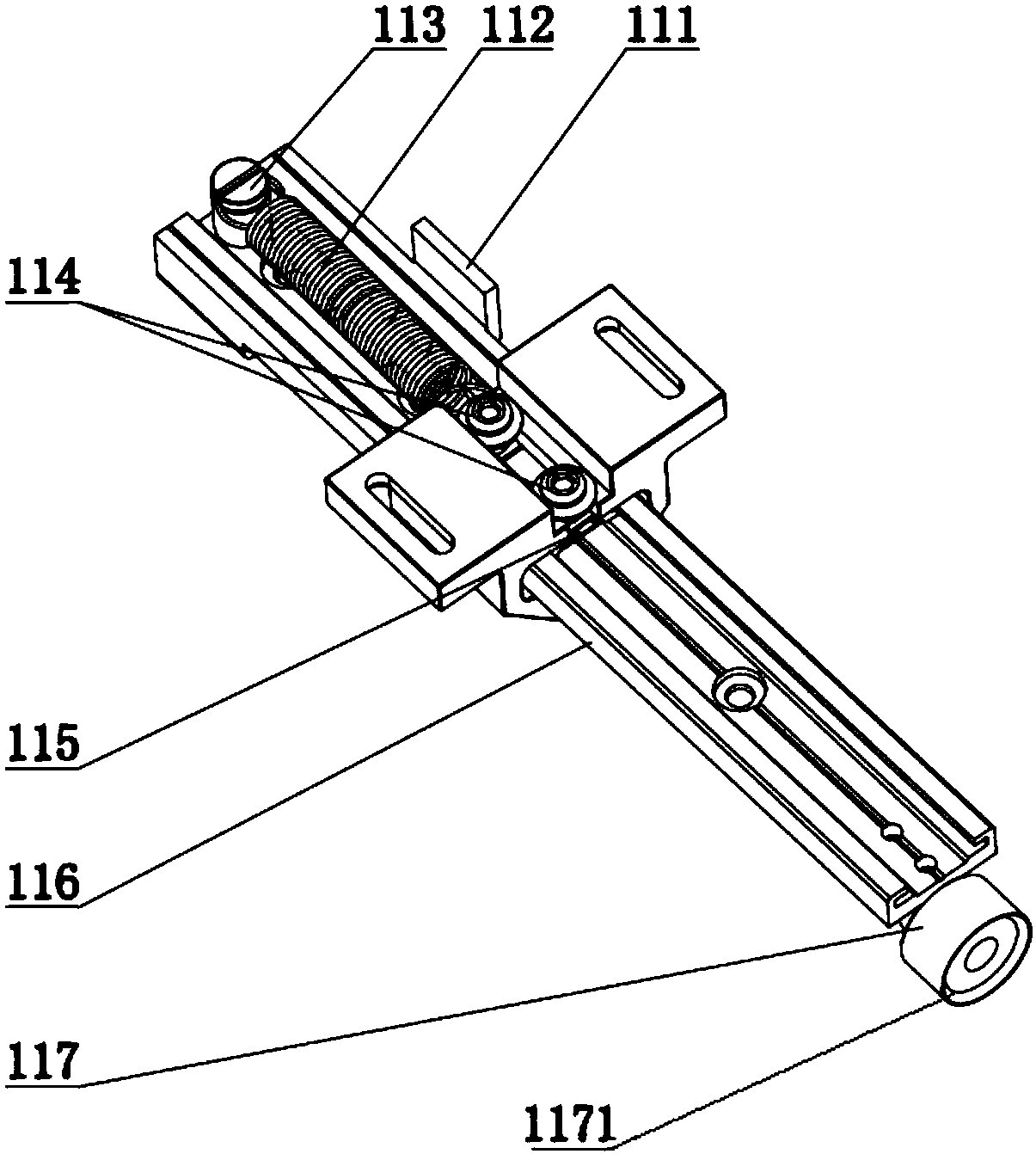

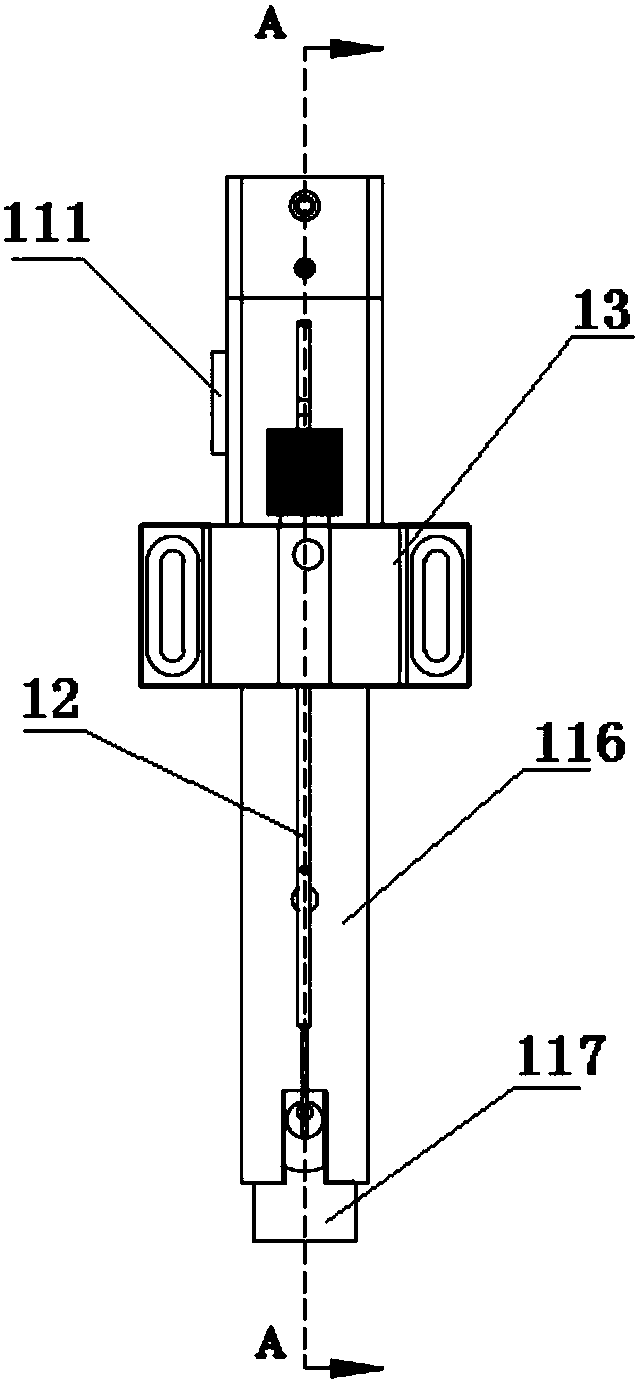

[0045] see figure 1 and Image 6, the present invention provides a bottle pressing assembly 1 of an autosampler, the autosampler includes an X-direction movement mechanism 2, a Y-direction movement mechanism 4 and a Z-direction movement mechanism 3, wherein the X-direction and Y-direction and the Z direction are perpendicular to each other in space, forming a mobile system in three vertical directions. The X and Y directions are located in the horizontal direction, and the Z direction is located in the vertical direction. The Z direction movement mechanism 3 is provided with a Z direction slider 32, and the Z direction slider 32 moves along the vertical direction under the action of the Z direction motor and the transmission mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com