Method of testing release rate and composition of gas released by calcium carbide dust upon contact with moisture

A technology for releasing gas and testing methods, which is applied in the field of testing the gas rate and components of calcium carbide dust when it is wet. It can solve the problems of poor release rate and composition detection, and achieve stable use and good technical effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

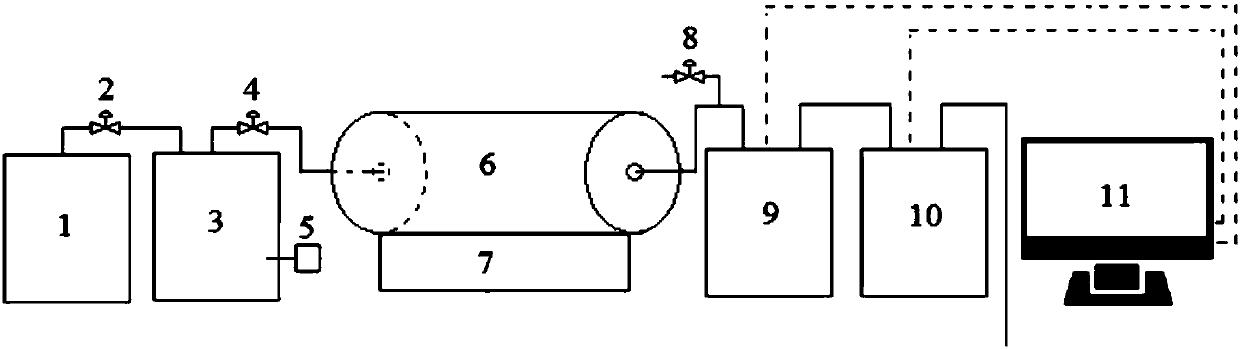

[0025] A test method for the gas rate and composition of calcium carbide dust when it is wet, such as figure 1 As shown, the main content of the present invention is a test method for the release rate and composition analysis of the flammable and explosive gas released by the reaction of water vapor and calcium carbide dust, which can generate water vapor with different humidity and simulate the actual working conditions of the calcium carbide production device. At the same time, the existing test method for the rate of flammable gas emission when wet is improved.

[0026] The test system for the gas rate and composition of calcium carbide dust when it is wet is mainly composed of the following parts:

[0027] 1) Steam generator: connected with the steam premixer for producing steam.

[0028] 2) Steam generator control valve: connected with the steam generator and the steam premixer, used to connect and shut off the steam from the steam generator to the steam premixer.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com