Motor brush holder and preparation method thereof

A technology of carbon brushes and conductive sheets, which is applied in the field of motor brush holders and its production, can solve the problems of unreasonable overall design and failure to solve the problems of exposed brushes, and achieve the effects of simple structure, stable and durable performance, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

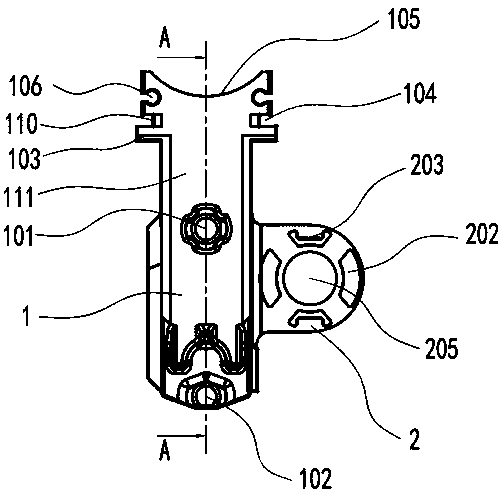

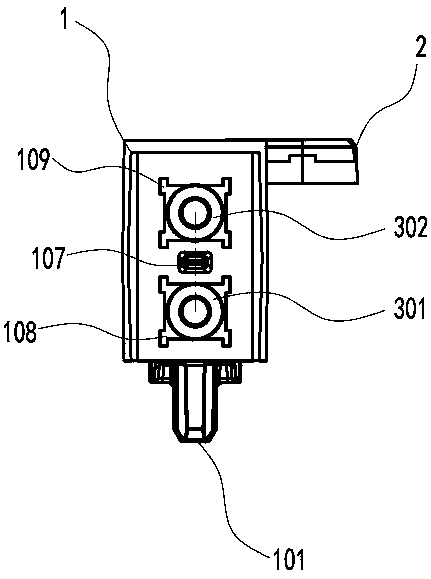

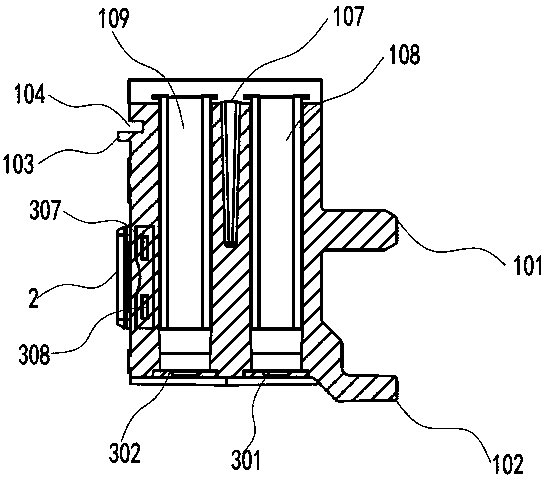

[0025] Such as Figure 1 to Figure 5 As shown, a motor brush holder of the present invention includes a primary injection molding shell 2, a secondary injection molding shell 1 and a circuit piece 3, the primary injection molding shell 2 is provided with a mounting through hole 205, and the circuit piece 3 includes a first conductive Sheet 301, second conductive sheet 302, first conductive block 303, second conductive block 304, first conductive hole 305, second conductive hole 306, first transitional conductive sheet 307, second transitional conductive sheet 308 and punching piece 309 , the first conductive block 303, the second conductive block 304, the first transitional conductive sheet 307, and the second transitional conductive sheet 308 are all injection-molded in the one-time injection molding shell 2, and the first conductive block 303 and the second conductive block 304 are all Only the exposed parts are set to be exposed to the primary injection molding shell 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com