Building waste material crushing system and construction method thereof

A pulverizing system and construction waste technology, applied in the direction of grain processing, etc., can solve the problems of slow discharge speed, affecting pulverization efficiency, inconvenient manual processing of residues, etc., and achieve the effect of improving discharge efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

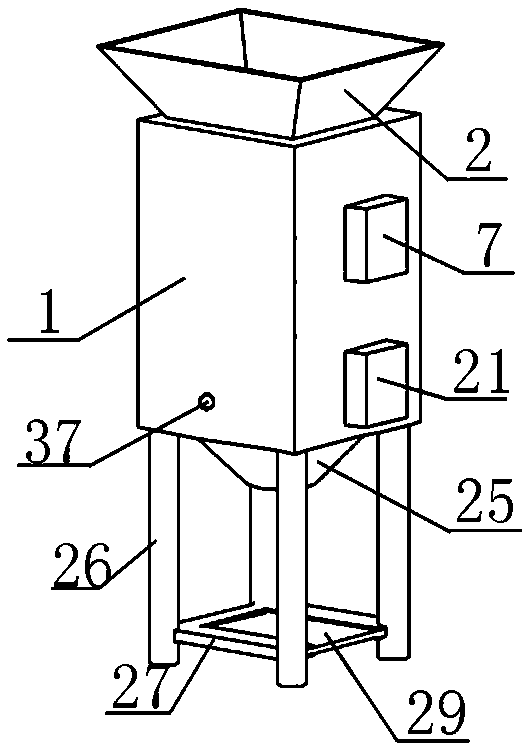

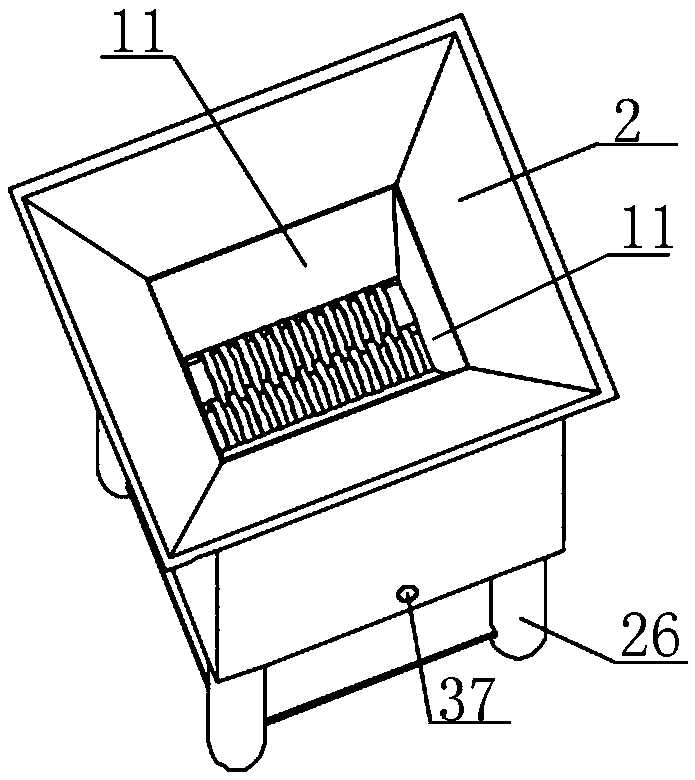

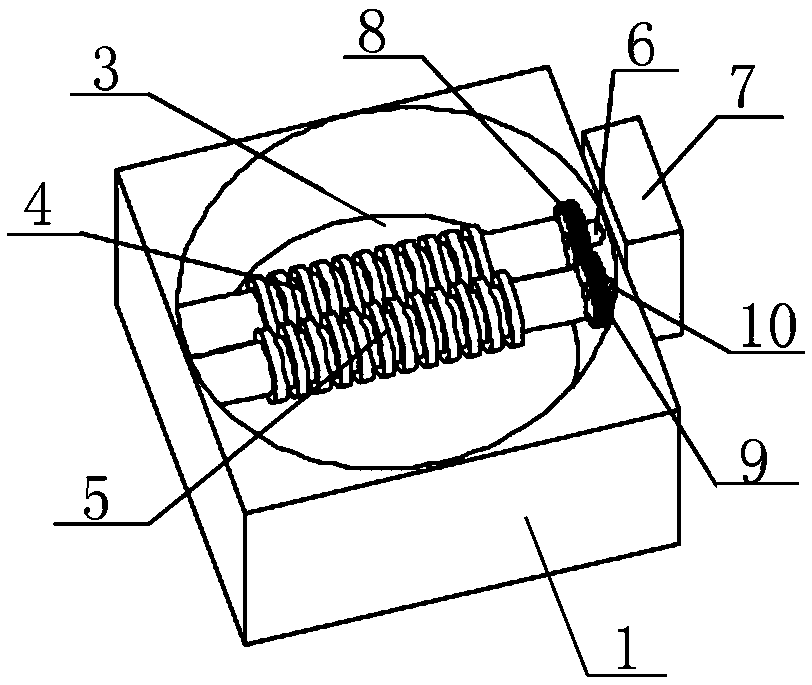

[0046] like Figure 1-12 As shown, this construction waste crushing system includes a crushing machine main body 1, a hopper 2, a hopper 25 and a vertical support 26; Inside, along the vertical axis, there is a cavity 3 that runs through the main body of the pulverizer 1; the upper part of the cavity 3 is a crushing chamber, and a crushing device is installed in the crushing chamber, and the lower part of the cavity 3 is a filter chamber, in which there is a filter chamber. device; the filter device is located directly below the crushing device, and is used to accept the crushed waste falling from the crushing device, and vibrate and filter the waste; the outer surface of the grinder main body 1 is connected with a control The first motor 7 for the operation of the crushing device and the second motor 21 for controlling the operation of the filter device; the feed hopper 2 is fixedly connected to the top of the grinder main body 1; the discharge hopper 25 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com