Safety protection window structure for high-speed machine tool

A technology of safety protection and windows, which is applied in the field of machine tools, can solve problems such as the danger of personnel around the equipment, and achieve the effects of low cost, saving manufacturing costs, and increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

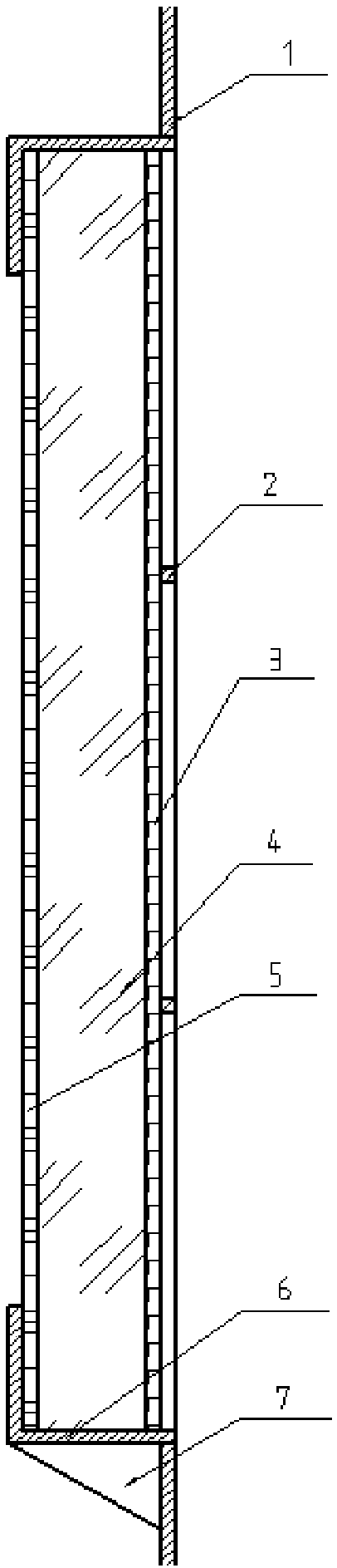

[0030] Such as figure 1 As shown, the present invention provides a safety protective window structure for high-speed machine tools, including a protective window steel plate 1, a protective window rib plate 2, an outer protective film 3 of the protective window, a main plate of the protective window 4, an inner plate of the protective window 5, a protective window Window main support structure 6 and the metal stiffener plate 7 of the entire high-speed machine tool protection window.

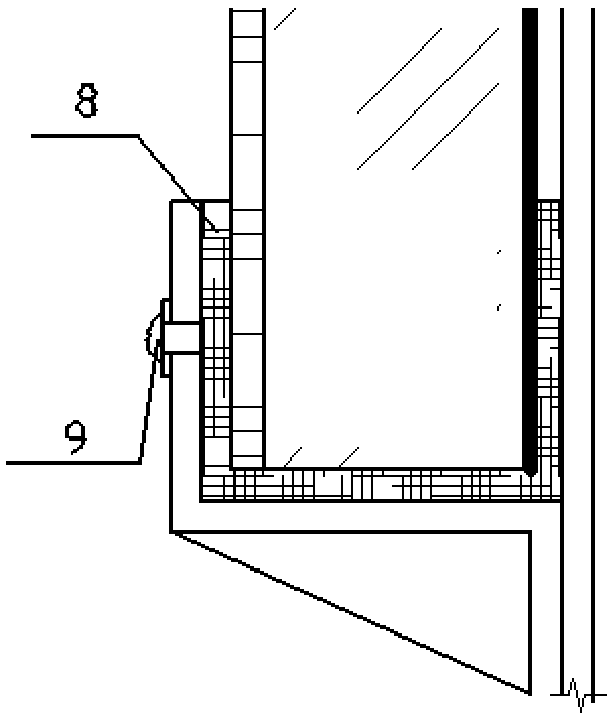

[0031] figure 2 It is shown that a supporting sealing rubber pad 8 is added between the inner panel 5 of the protective window and the main support structure 6 of the protective window, and is fixed by a plurality of fixing screws 9 .

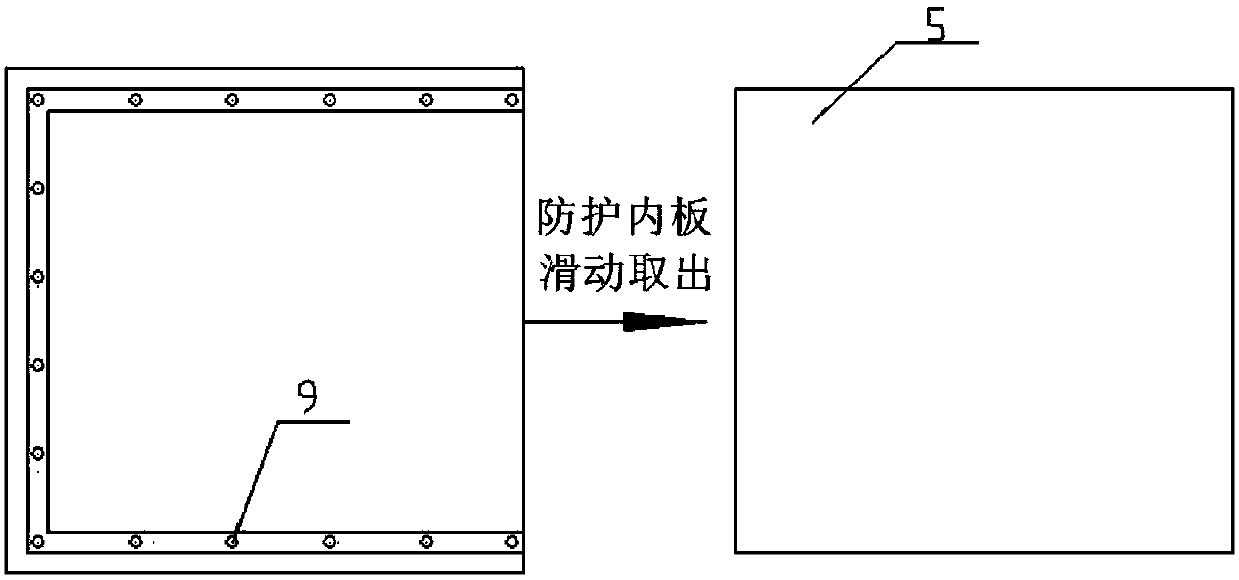

[0032] image 3 Shown is that the protective inner plate 5 is usually fixed by the fixing screw 9 and the main support structure 6 of the protective w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com