Automatic cup bottom and cup body forming machine of circular truncated cone-shaped food packaging box

A food packaging box, circular cone-shaped technology, applied in the field of food packaging box forming machinery, can solve the problems of affecting the work progress, cumbersome and complicated process, and difficult to arrange, so as to reduce labor intensity, ensure personnel safety, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

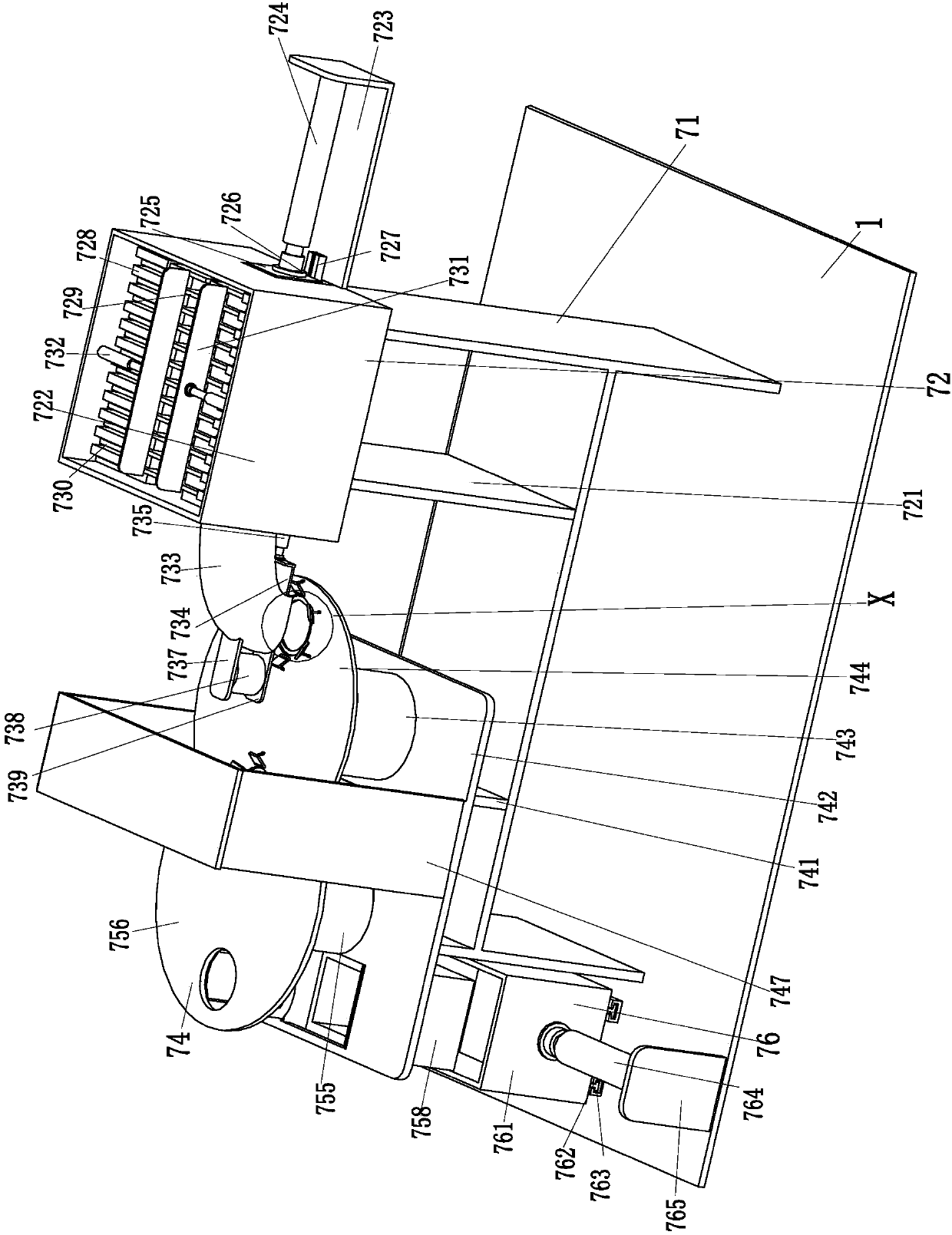

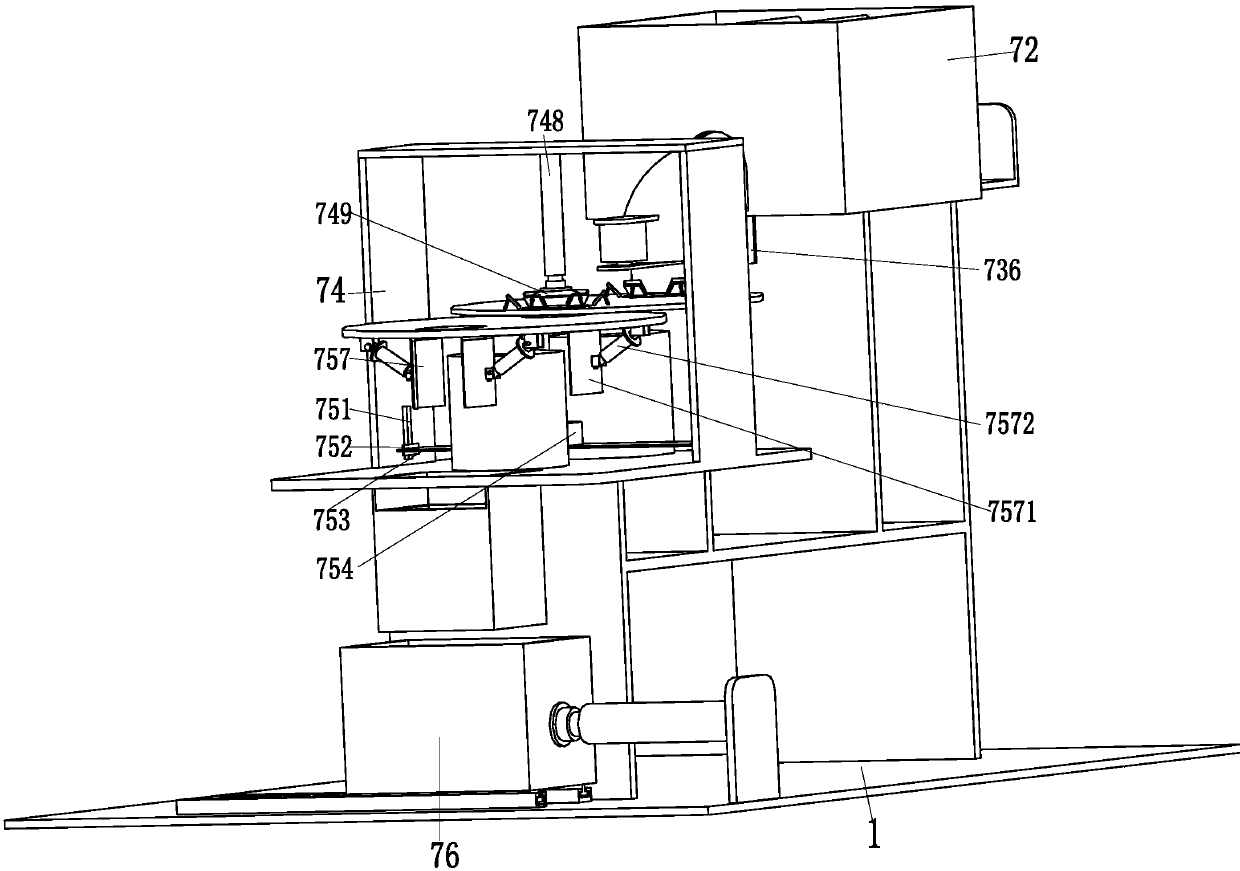

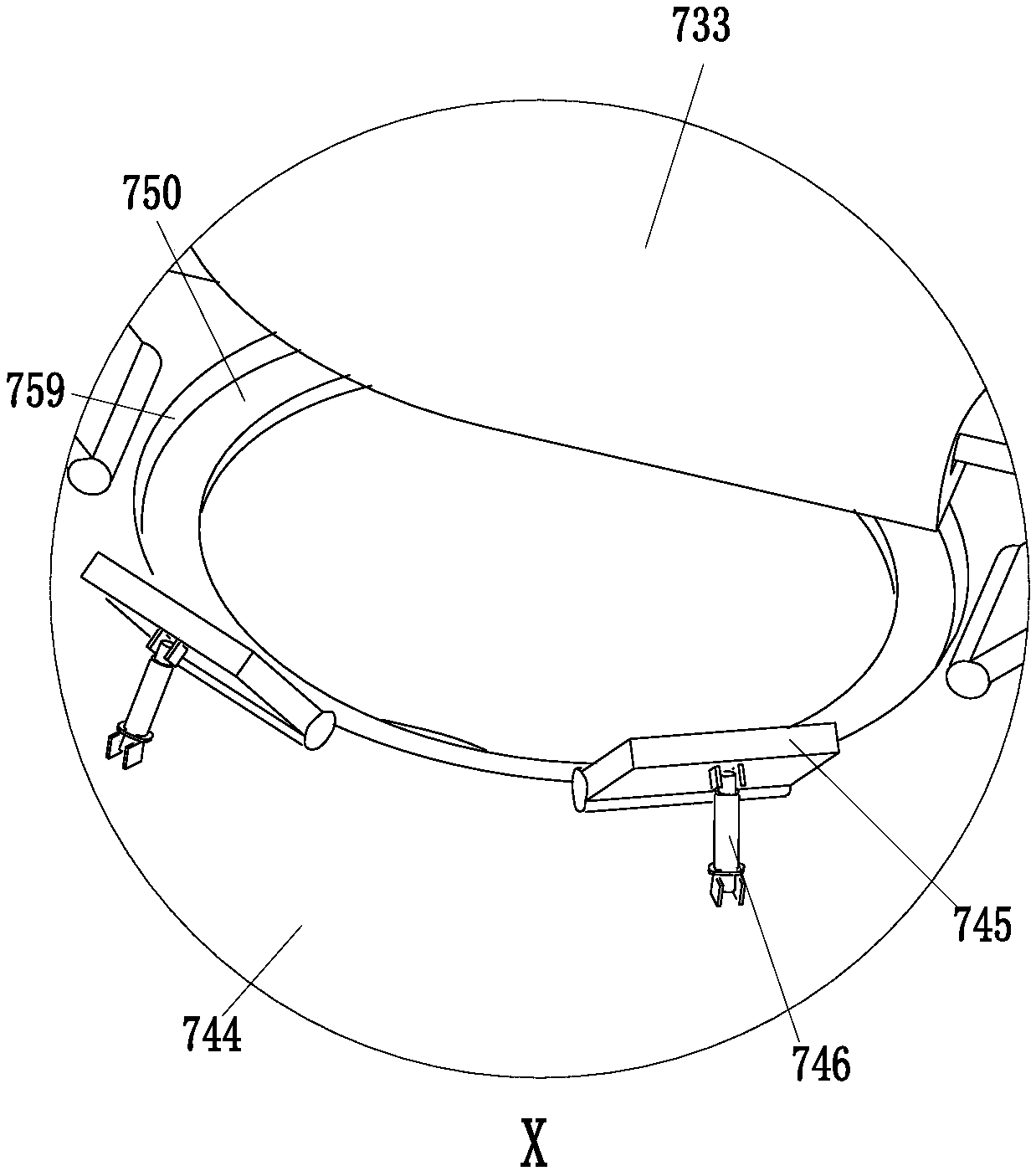

[0021] Such as Figure 1 to Figure 3 As shown, in order to achieve the above object, the present invention adopts the following technical solutions: a cup bottom and cup body automatic molding machine for a conical food packaging box, including a bottom plate 1, a work frame 71, a finishing mechanism 72, and a cup bottom forming mechanism 74 And collection mechanism 76, finishing mechanism 72 arranges and transports the cup bottom paper, cup bottom forming mechanism 74 carries out molding processing with the cup body and the cup bottom, and collecting mechanism 76 conveys out the rou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap