Tidying and transferring device for kelp after being harvested

A technology of transfer device and sorting device, which is applied in the directions of transportation and packaging, food processing, loading/unloading, etc., which can solve the problems of hard labor and high labor intensity, and achieve the effect of single function, reduced labor intensity, and high efficiency of netting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

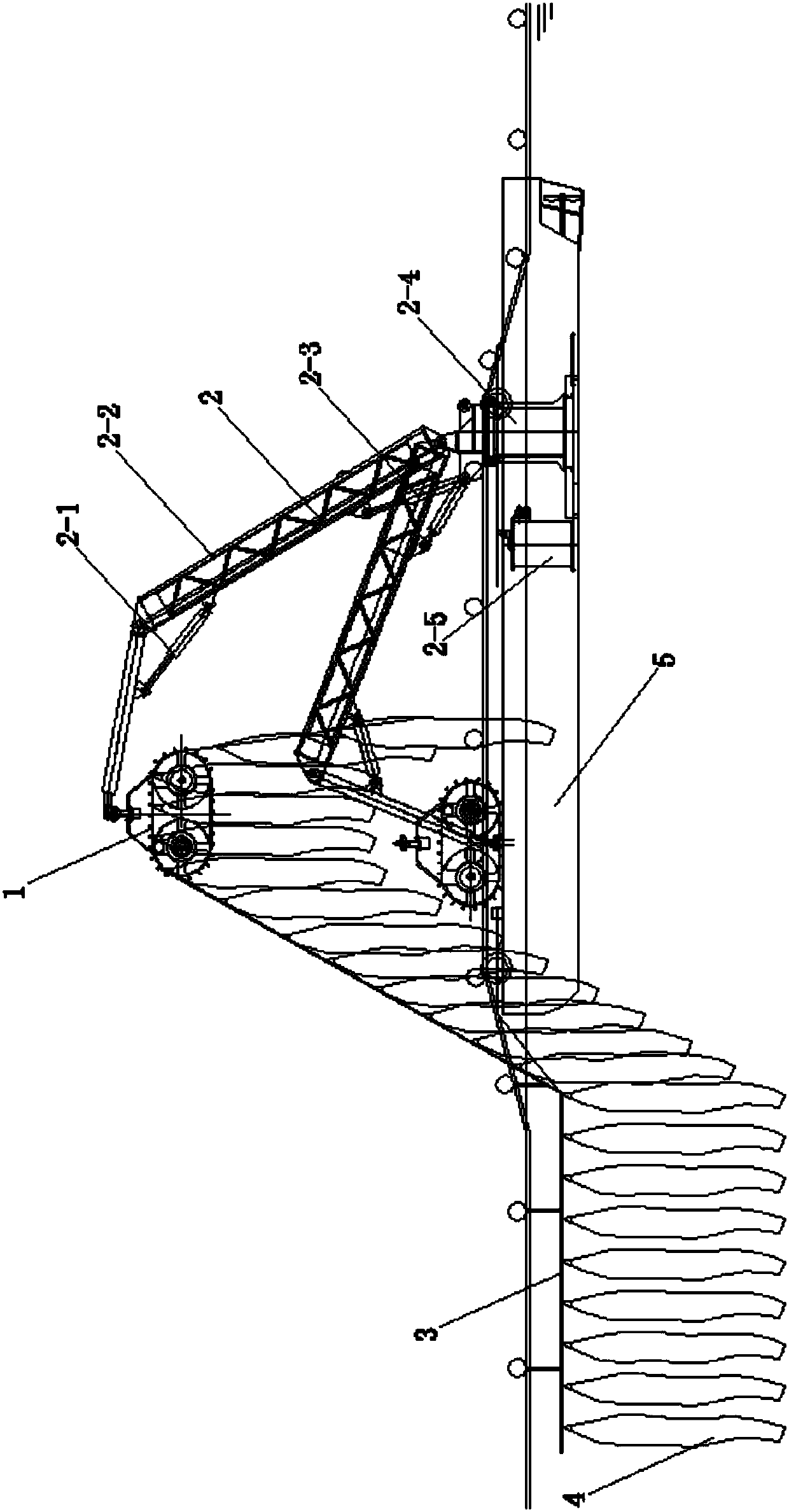

[0026] see figure 1 , a sorting machine for growing kelp after harvesting, comprising a sorting device 1 for growing kelp, a turning and folding arm lifting and transferring device 2 , a kelp growing rope 3 , and kelp 4 . As can be seen from the figure, the kelp fully loaded with kelp 4 grows into a rope 3 . The rotating and folding arm hoisting and transferring device comprises a folding arm oil cylinder 2-1, an arm frame 2-2, a lifting oil cylinder 2-3, a slewing seat 2-4, and a hydraulic pump station 2-5.

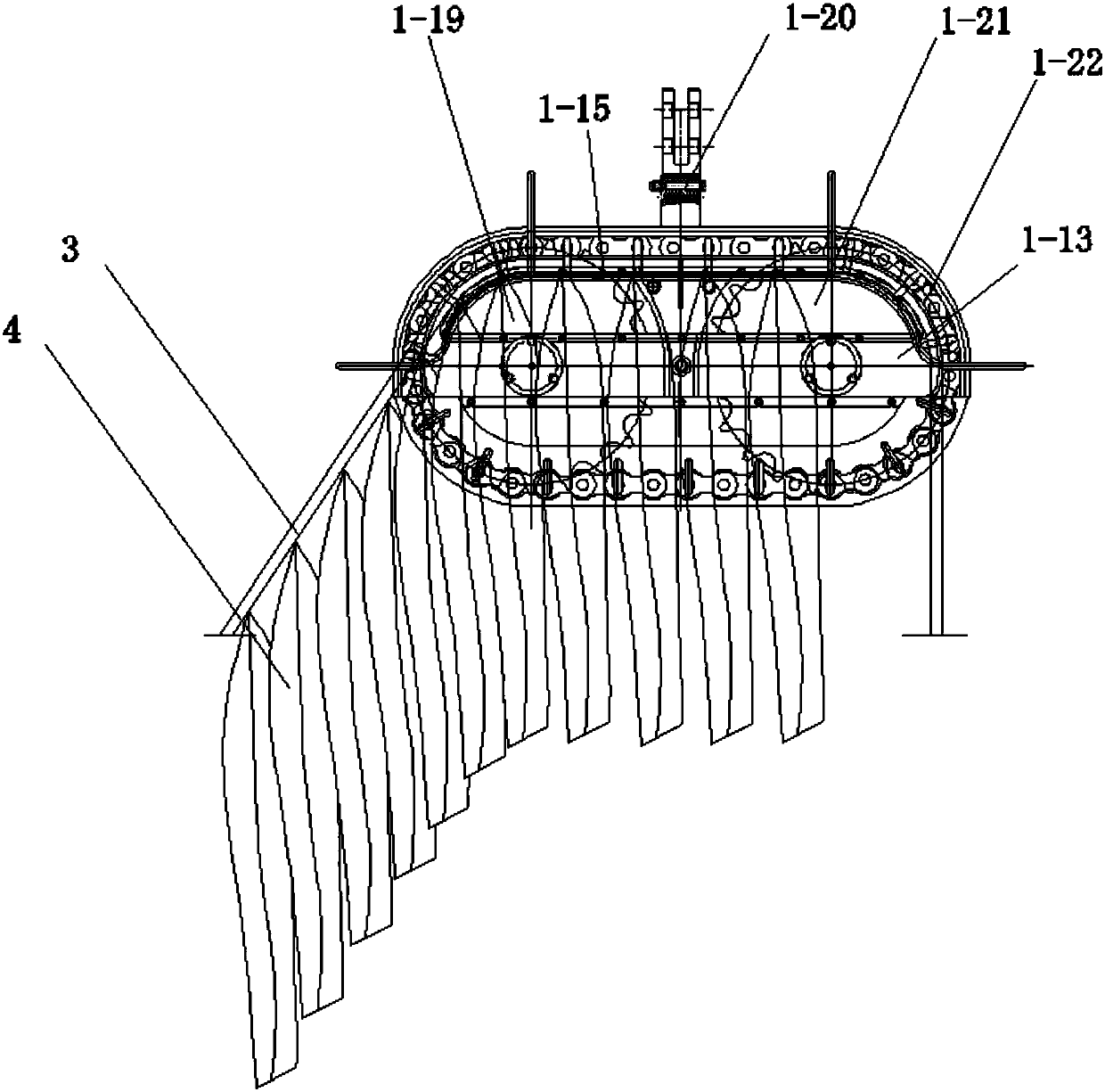

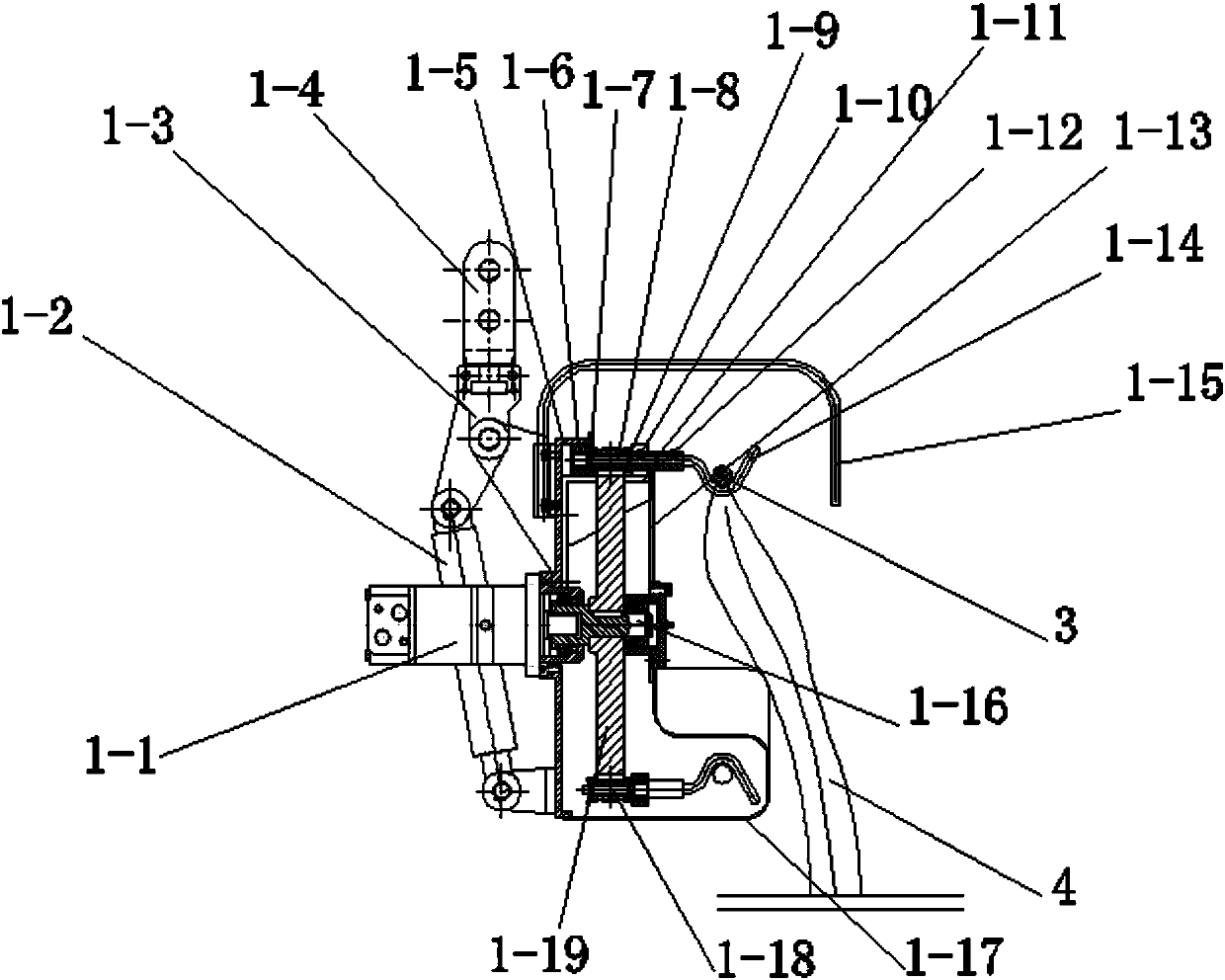

[0027] see Figure 2 to Figure 3 , forming a kelp finishing device, including a hydraulic motor 1-1, an oil cylinder 1-2, a lifting rotating part 1-3, a lifting fixing part 1-4, a wall frame 1-5, a left roller 1-6, and an outer chain piece 1 -7, long pin shaft 1-8, pin 1-9, right roller 1-10, connecting sleeve 1-11, support frame rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com