Device and method for producing high-strength compound fertilizer by using of compound fertilizer return material

A compound fertilizer and high-strength technology, applied in fertilization equipment, urea compound fertilizer, solid/semi-solid fertilizer, etc., can solve the problems of low pelleting rate, large product powder, low yield, etc., and achieve high-strength moisture absorption resistance, Reasonable process design and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

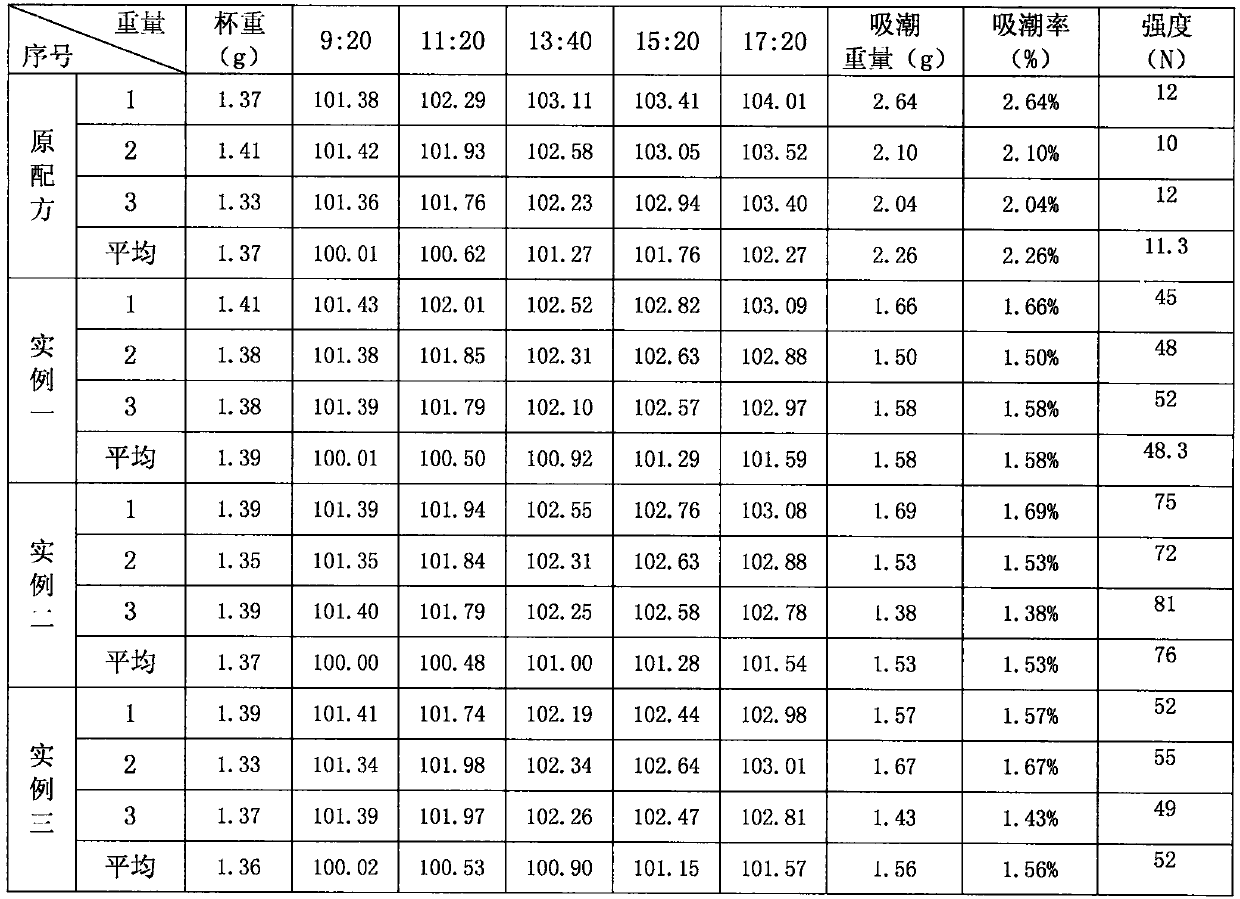

Embodiment 1

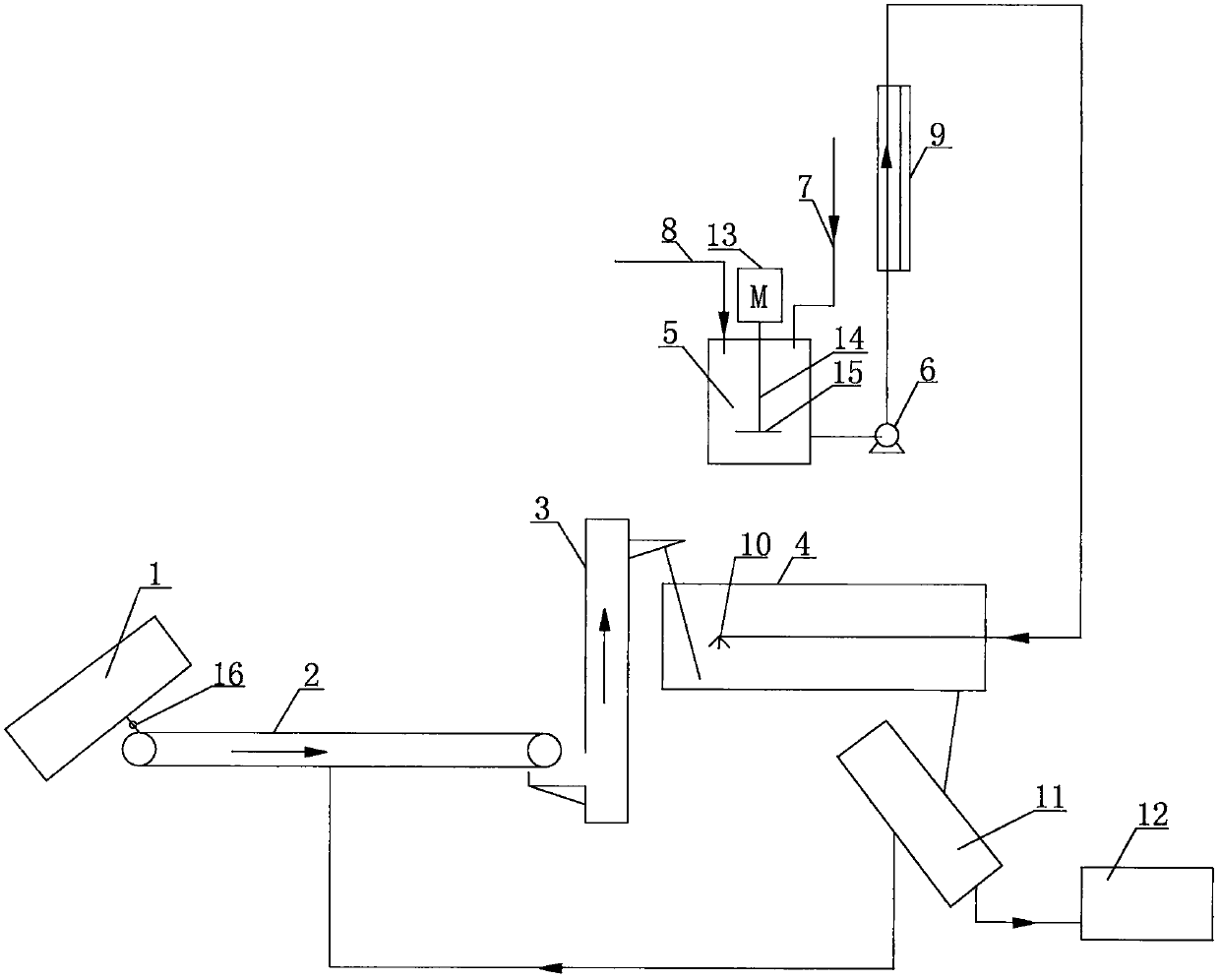

[0028] A device for producing high-strength compound fertilizer by using compound fertilizer return materials, comprising a return port of a compound fertilizer finished product screen 1, the return port of the compound fertilizer finished product screen 1 is connected to a bucket elevator 3 through a belt scale 2, The material outlet of the bucket elevator 3 is connected with the material inlet of the granulator 4, and the upper part of the material inlet of the granulator 4 is provided with a compound fertilizer granule spraying device, and the material outlet of the granulator 4 is respectively connected to the packing scale 12 through the screen 11. Connect to each other; Described compound fertilizer granule spraying device comprises stirring tank 5, and the top of stirring tank 5 is provided with molten urea solution pipeline 7, additive pipeline 8 and stirring motor 13, and stirring motor 13 is mixed with stirring main shaft 14 by stirring tank 5 insides. The blades 15 a...

Embodiment 2

[0039] A device for producing high-strength compound fertilizer by using compound fertilizer return materials, comprising a return port of a compound fertilizer finished product screen 1, the return port of the compound fertilizer finished product screen 1 is connected to a bucket elevator 3 through a belt scale 2, The material outlet of the bucket elevator 3 is connected with the material inlet of the granulator 4, and the upper part of the material inlet of the granulator 4 is provided with a compound fertilizer granule spraying device, and the material outlet of the granulator 4 is respectively connected to the packing scale 12 through the screen 11. Connect to each other; Described compound fertilizer granule spraying device comprises stirring tank 5, and the top of stirring tank 5 is provided with molten urea solution pipeline 7, additive pipeline 8 and stirring motor 13, and stirring motor 13 is mixed with stirring main shaft 14 by stirring tank 5 insides. The blades 15 a...

Embodiment 3

[0050] A device for producing high-strength compound fertilizer by using compound fertilizer return materials, comprising a return port of a compound fertilizer finished product screen 1, the return port of the compound fertilizer finished product screen 1 is connected to a bucket elevator 3 through a belt scale 2, The material outlet of the bucket elevator 3 is connected with the material inlet of the granulator 4, and the upper part of the material inlet of the granulator 4 is provided with a compound fertilizer granule spraying device, and the material outlet of the granulator 4 is respectively connected to the packing scale 12 through the screen 11. Connect to each other; Described compound fertilizer granule spraying device comprises stirring tank 5, and the top of stirring tank 5 is provided with molten urea solution pipeline 7, additive pipeline 8 and stirring motor 13, and stirring motor 13 is mixed with stirring main shaft 14 by stirring tank 5 insides. The blades 15 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com