Braiding machine inner spindle

A knitting machine and spindle technology, applied in knitting, textile and paper making, etc., can solve the problems of reducing production efficiency, weaving disorder, affecting product production and finished product quality, etc., and achieving the effect of quality assurance, flexibility and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

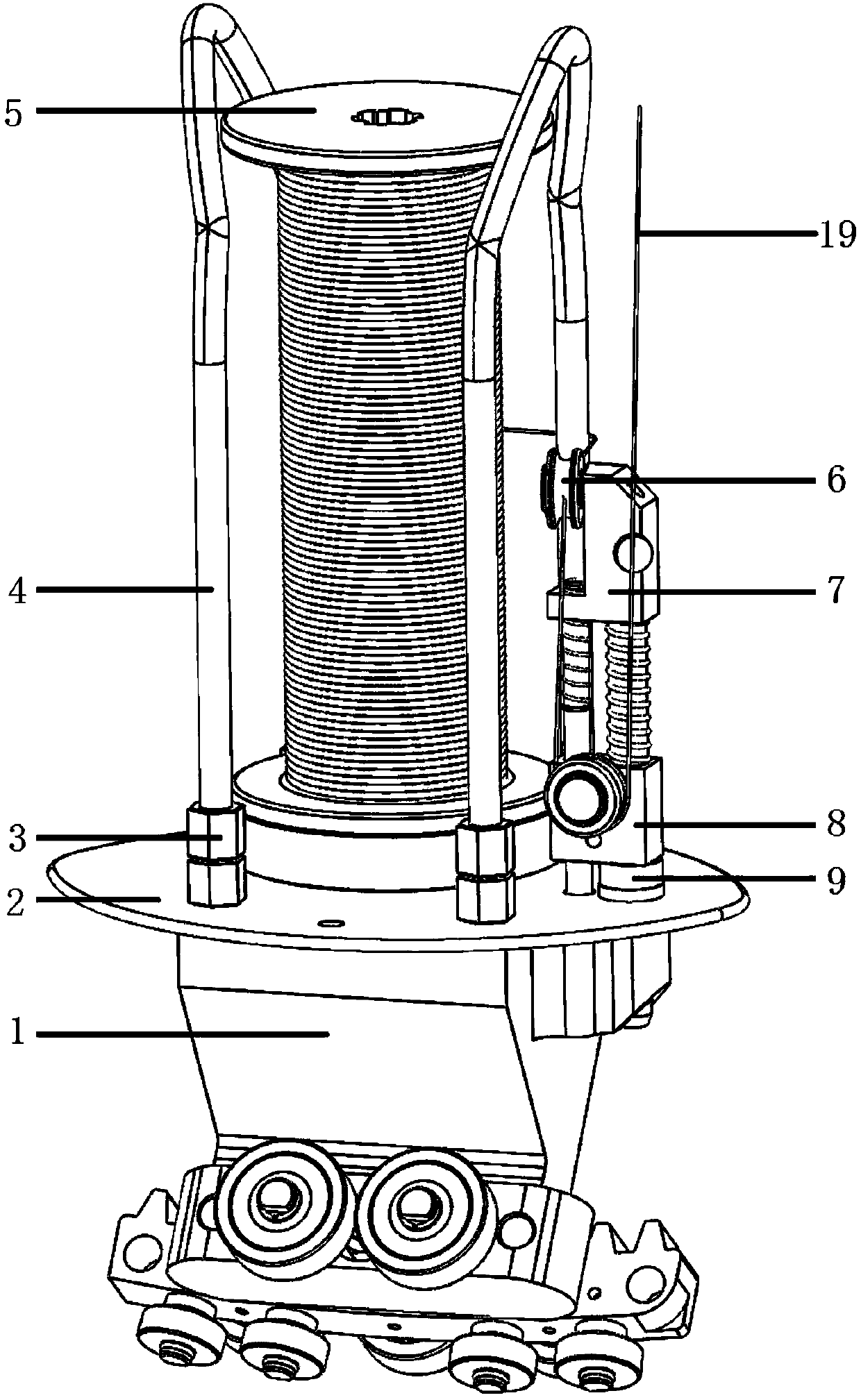

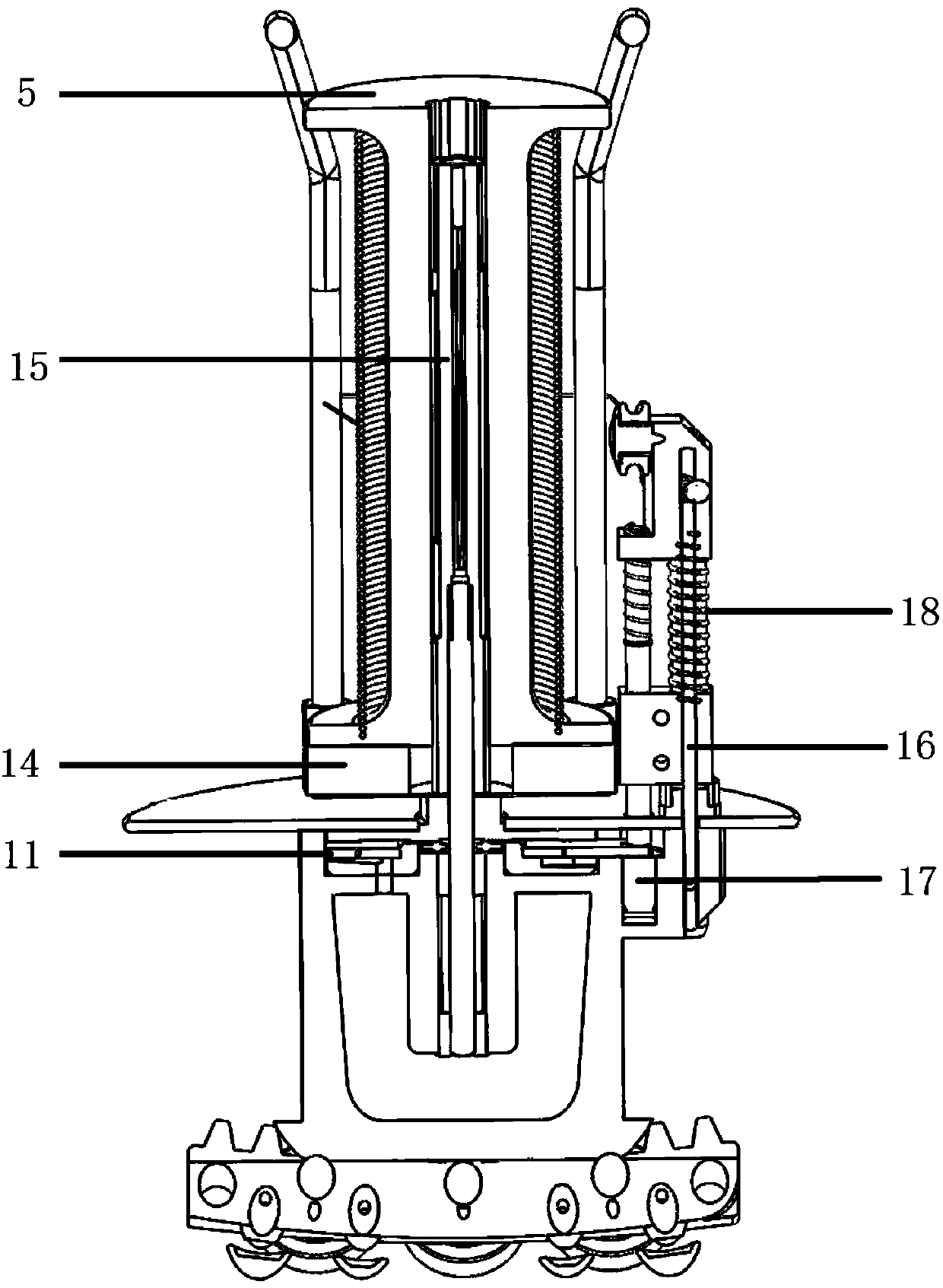

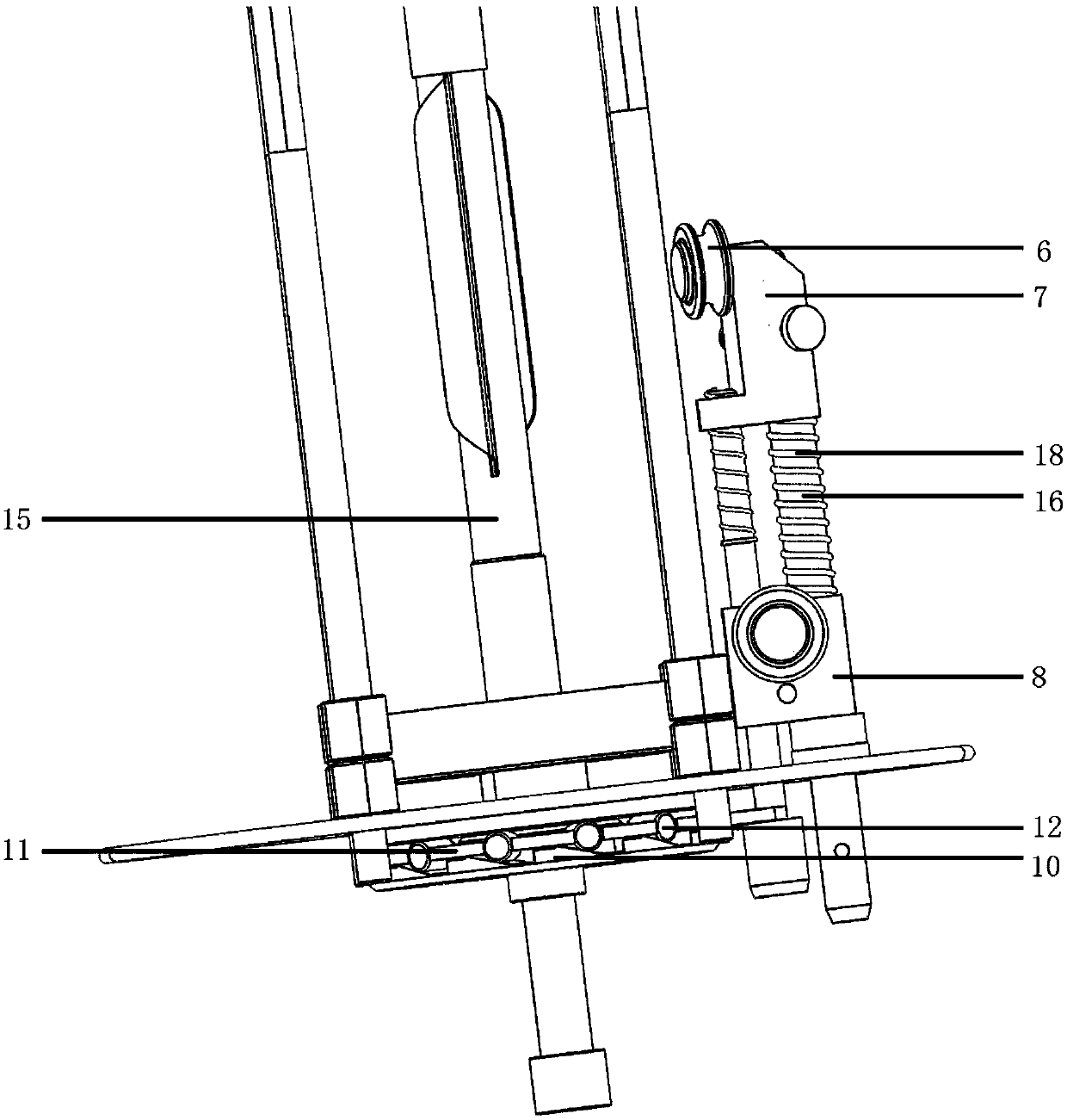

[0026] The technical solution of the present invention will be further described in conjunction with the accompanying drawings.

[0027] Such as Figure 1-9 As shown, an inner spindle of a braiding machine includes an inner spindle body 1, a ratchet disc 10, an inner spindle deck 2, a guide rod 16, a sleeve 9, a slider 8, a top block 7, a brake lever 17, a spindle rod, a holding Frame 11, roller 12, friction disc 13, off-line U-shaped bar 4, ratchet disc 10 is arranged at the bottom of inner spindle body 1, and roller 12 is arranged on the inclined surface of ratchet disc 10, and roller 12 is held by the upper part of ratchet disc 10. The frame 11 is used to fix the position. When the cage 11 rotates on the ratchet disk 10, the roller 12 moves up and down on the slope of the ratchet disk 10. One side of the cage 11 has a protruding handle structure, and the end has an inclined notch. , the notch is connected with the brake rod passing through the inner spindle body 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com