Screw pump cam type centering turnover plate anchor

A technology of cam type and flap anchor, which is applied in the direction of drill pipe, drilling equipment, wellbore/well parts, etc., can solve the problems of tubing bending, vibration intensification, and radial eccentric wear of tubing, so as to prevent spring performance and eliminate Vibration, avoiding the effect of severe bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

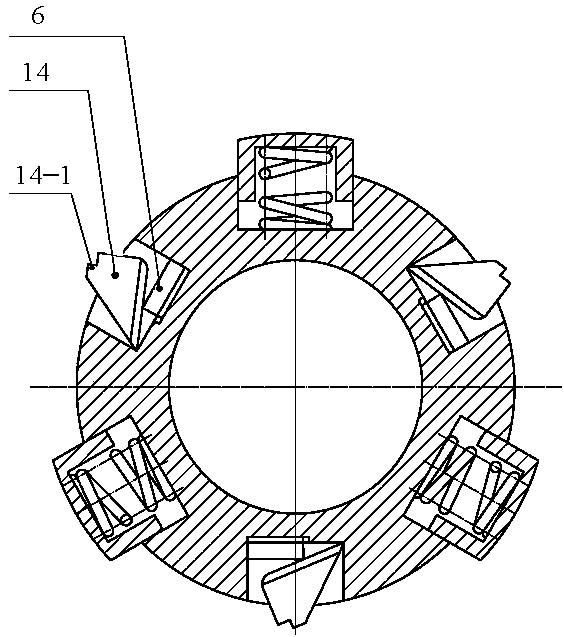

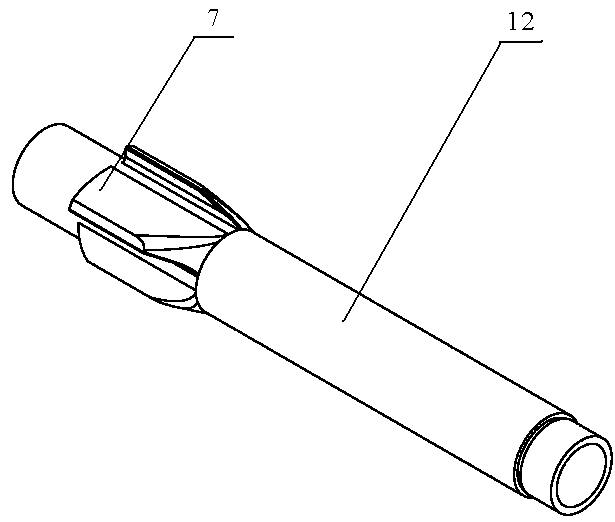

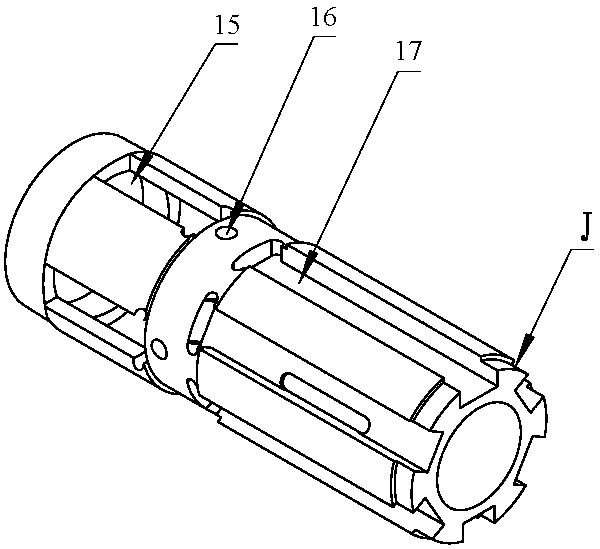

[0012] Attached below Figure 1-5 The present invention is described in further detail:

[0013] The specific structure is as follows: the upper joint 1 is threaded to the upper central tube 12; the upper part of the upper central tube 12 is provided with four sliding cam surfaces 7 uniformly distributed along the circumferential direction; the main body 2 is set on the lower end of the upper joint 1, and the spring seat 10 is set on the upper central tube 12 and is connected with the thread J of the main body 2, the upper center pipe 12 is threadedly connected with the lower center pipe 13, and a large spring 18 is assembled between the spring seat 10 and the positioning piece 19 on the lower center pipe 13; There are four strip-shaped holes 15, and slips 4 are arranged in the holes, and the arc-shaped lower end surface of slips 4 is in contact with the sliding cam surface 7. Several spring holes 16 are arranged on the main body, and the spring 3 is pressed onto the spring b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com