Device and method for prefabricating local beneficial wrinkles of pipe

A kind of pipe material and beneficial technology, which is applied in the field of prefabricated pipe material local beneficial wrinkles, can solve the problems affecting the pipe material quality, pipe bending, pipe buckling, etc., and achieve the effect of avoiding global buckling and severe bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

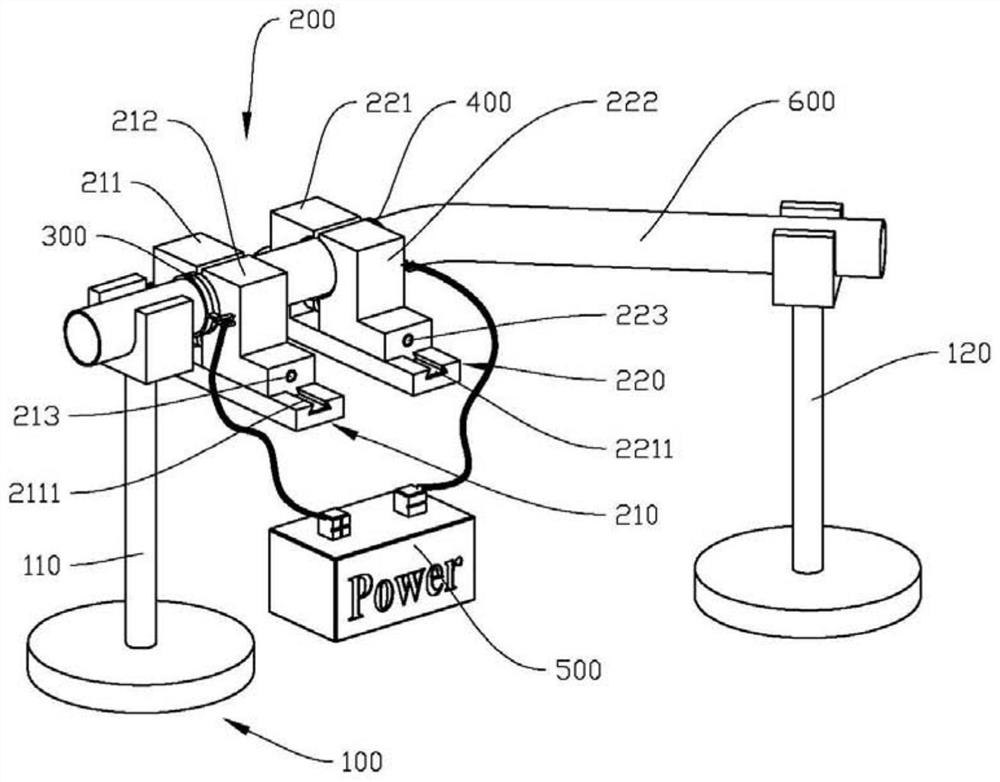

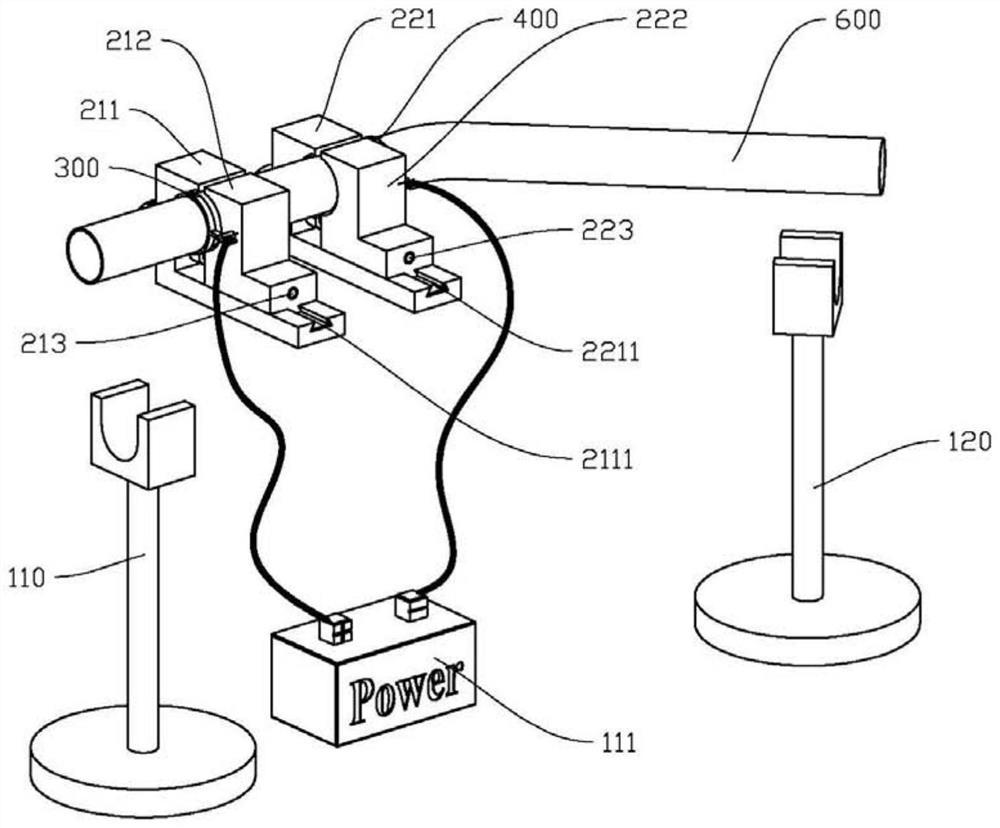

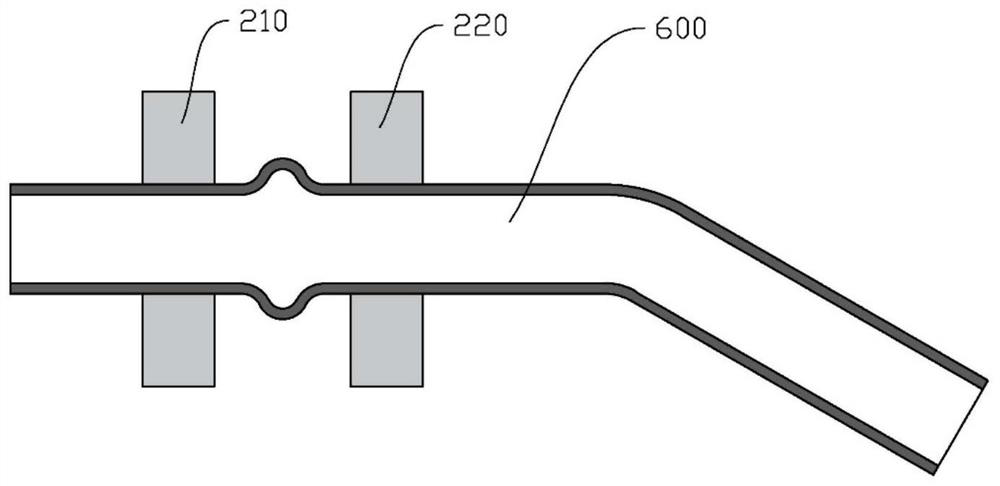

[0031] Embodiments of the present invention are described in detail below, with reference to figure 1 , the embodiment of the present invention provides a device for prefabricating local beneficial wrinkles of pipes, including a support assembly 100 and a clamping assembly 200, the support assembly 100 includes a first support frame 110 and a second support frame 120; the clamp assembly 200 includes a first A manipulator 210 and a second manipulator 220. The first manipulator 210 and the second manipulator 220 are respectively equipped with a first electrode contact 300 and a second electrode contact 400. The first manipulator 210 and the second manipulator 220 can hold pipes respectively 600 at both ends of the position to be wrinkled, the first electrode contact 300 and the second electrode contact 400 can locally heat the position of the pipe 600 to be wrinkled, and the first manipulator 210 and the second manipulator 220 can move toward each other to heat the pipe 600 Axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com