Internal circular cooling ball screw device

A ball screw and internal circulation technology, which is applied in the direction of transmission, transmission parts, gear lubrication/cooling, etc., can solve the problems that affect the performance of the ball screw device, do not add a cooling and cooling device, and accelerate the friction loss of balls. Achieve the effect of reducing heat, small size and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

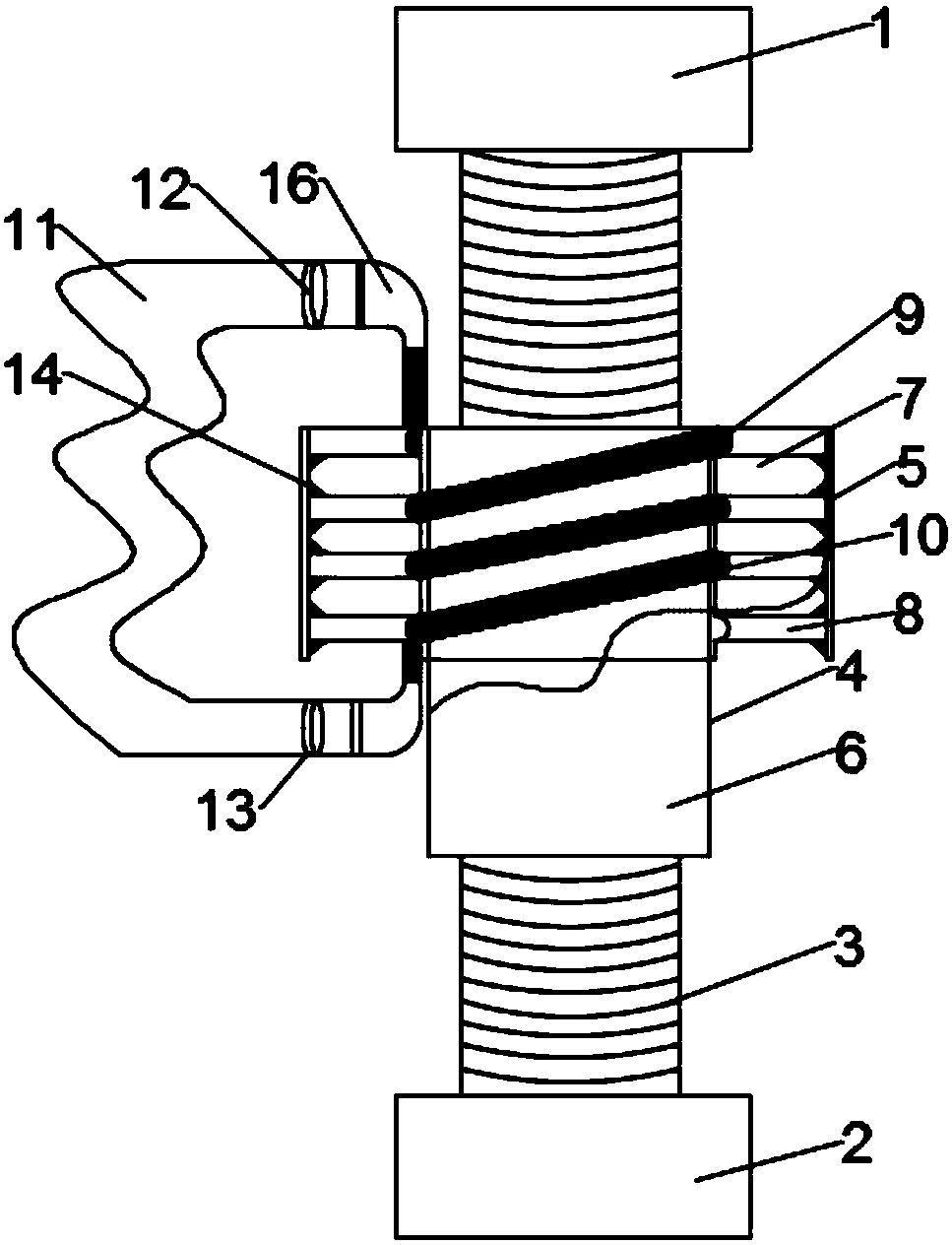

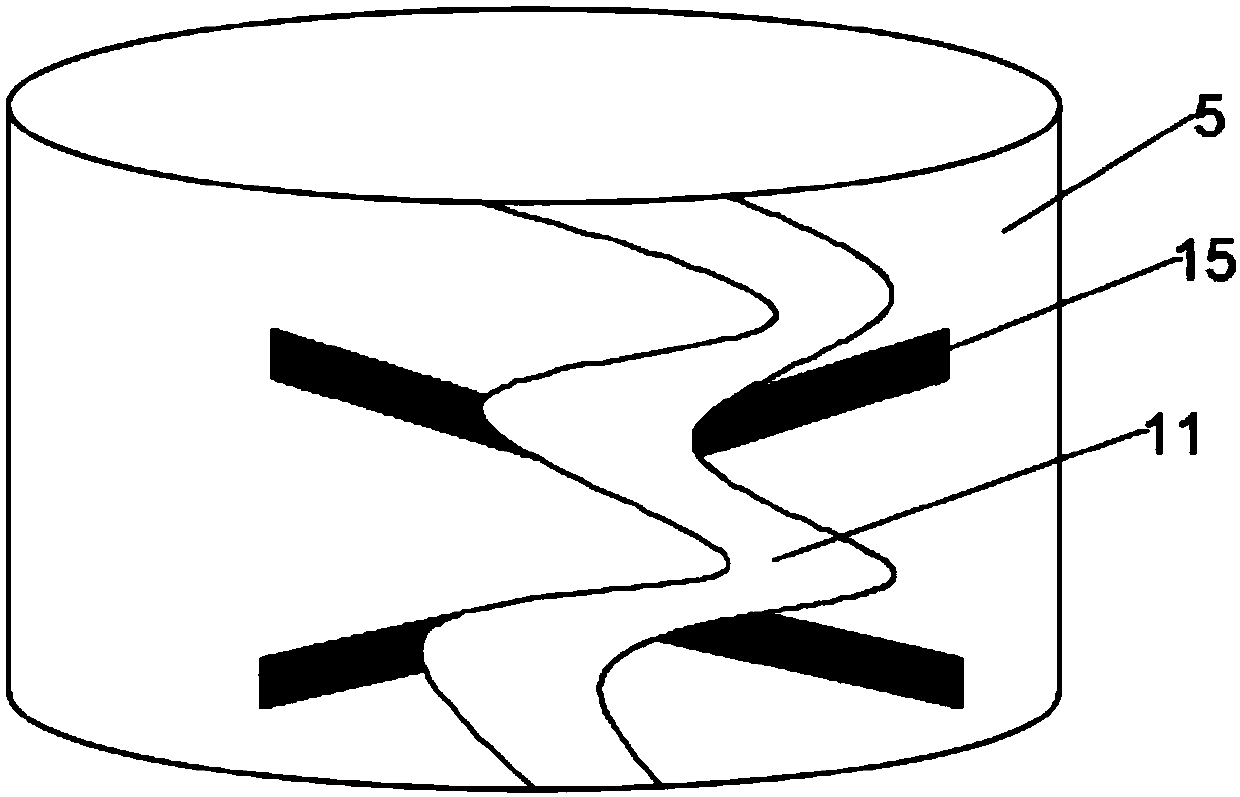

[0020] Such as figure 1 and figure 2 As shown, the present invention provides a ball screw device with internal circulation cooling, comprising an upper limit block 1 and a lower limit block 2, a screw 3 is arranged between the upper limit block 1 and the lower limit block 2, and the Lead screw 3 is provided with nut seat 4, and described nut seat 4 comprises large cylinder 5 and small cylinder 6, and described large cylinder 5 is socketed on the small cylinder 6, and described small cylinder 6 is provided with The thread corresponding to the lead screw 3, and the thread is filled with ball strings, the upper limit block 1 and the lower limit block 2 on the one hand play the role of limiting the stroke of the device when the ball screw device moves, and on the other hand On the one hand, it also plays a stable role for the ball screw device, and threaded fixing holes can be added on the upper limit block 1 and the lower limit block 2, so as to be fixed on other platforms.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com