Device capable of performing self-positioning multi-angle loading aging test on multiple torsional springs

An aging test and multi-angle technology, which is applied in the direction of measuring device, using stable torsion to test material strength, strength characteristics, etc., can solve the problems of not being able to meet small batch testing and complicated operation process, so as to save test cost and operate conveniently , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

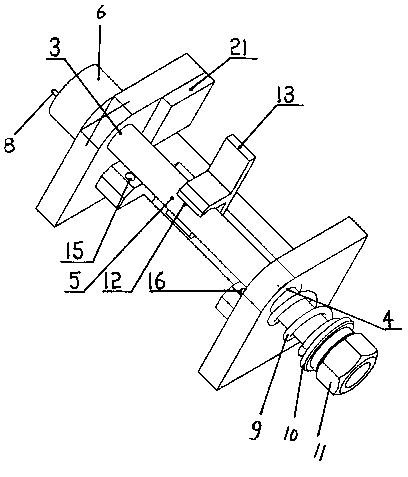

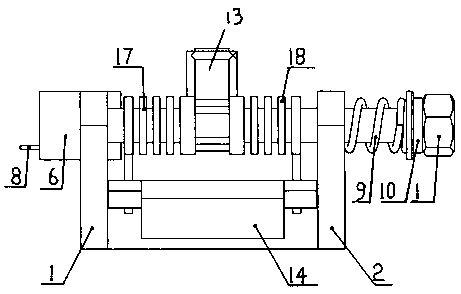

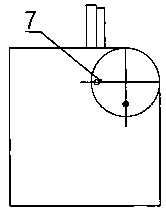

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

[0014] A self-positioning multi-angle loading aging test device for a plurality of torsion springs, including a left bracket baffle 1 and a right bracket baffle 2, and a connection between the left bracket baffle 1 and the right bracket baffle 2 Plate 14, on the left bracket baffle plate 1, be provided with pin shaft and pass through the left through hole 3, on the right bracket baffle plate 2, be provided with pin shaft through the right through hole 4, pass through the left through hole 3 and the pin shaft through the right A pin shaft rod 5 is movably inserted between the through holes 4, and a pin shaft head 6 is fixedly arranged on the left end of the pin shaft rod 5 passing out to the pin shaft through the left through hole 3, and a pin shaft head 6 is fixedly arranged on the left end of the pin shaft rod 5 passing through the left through hole 3, and a pin shaft head 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com