An error testing preventing method for polymer lithium ion battery short circuit tests

A lithium-ion battery, short-circuit test technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of difficulty in production and detection of polymer lithium-ion batteries, affecting product performance and safety, missed detection, and false detection ratios. , to achieve the effect of facilitating development and design, reducing equipment failure and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with specific examples and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

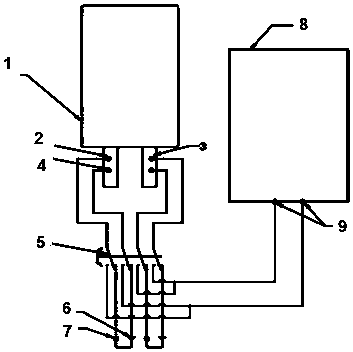

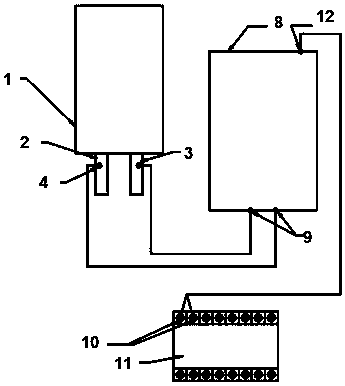

[0013] Such as figure 2 Shown is a lithium-ion battery short-circuit test anti-mis-test method device, including a PLC controller, an insulation short-circuit tester and an electric control circuit. The positive pole ear 2 and the negative pole ear 3 on the battery 1 are respectively connected through the probe 4, and are connected to the test lead output port 9 of the insulation short circuit tester 8, and the signal output port 12 of the insulation short circuit tester is connected to the PLC control through conversion into a contact structure In the input port 10 of the device 11.

[0014] Start the insulation short-circuit tester 8, there will be a very short charging process between the positive and negative pole ears 2 and 3 of the battery 1, the insulation sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com