Workbench and Exposure Device

A workbench and workpiece technology, which is applied in the exposure device of photolithography process, microlithography exposure equipment, optics, etc., can solve the problems of workpiece deformation and vacuum adsorption, and achieve simple structure, low cost, easy operation and positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Next, modes for carrying out the invention of the present application (hereinafter referred to as embodiments) will be described.

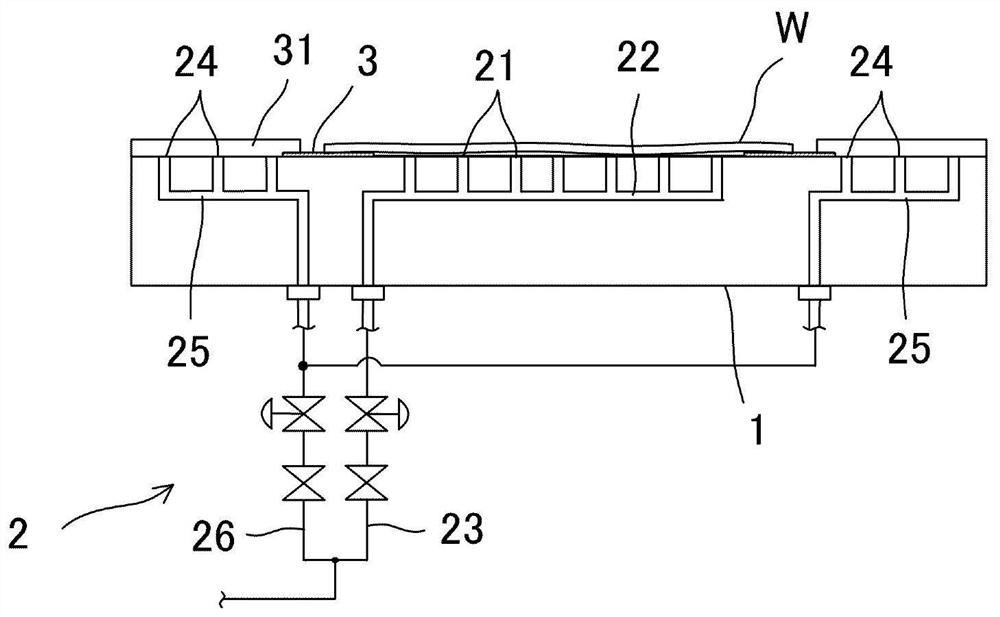

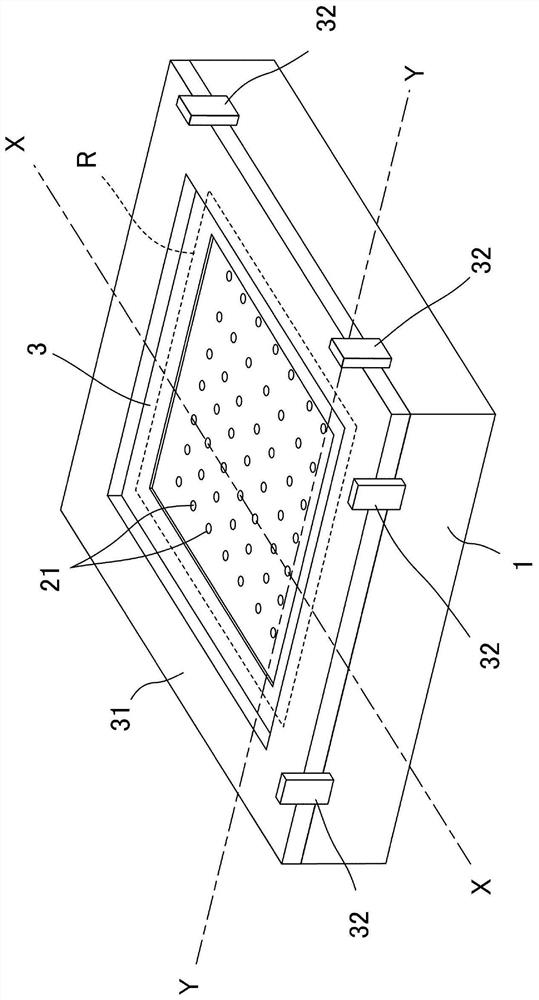

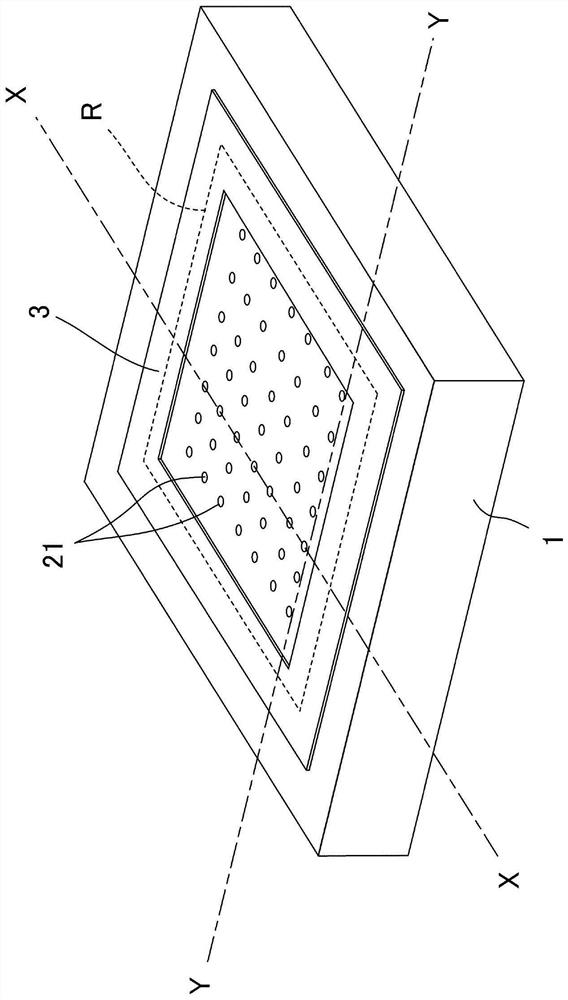

[0059] figure 1 It is a schematic front cross-sectional view of the workbench of the embodiment, figure 2 for figure 1 A schematic perspective view of the workbench shown, image 3 for figure 1 A schematic perspective view of the main parts of the workbench shown.

[0060] Figure 1 ~ Figure 3 The table of the illustrated embodiment holds a plate-shaped workpiece W and includes a table main body 1 . The table main body 1 is a rectangular table-shaped member in plan view. In this embodiment, the table main body 1 holds the workpiece|work W in a horizontal posture, and the upper surface which is a horizontal flat surface becomes a workpiece|work holding surface.

[0061] Such as Figure 1 ~ Figure 3 As shown, the table main body 1 has a plurality of vacuum suction holes 21 for workpieces. On the upper surface of the table main body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com