Steam turbine generator magnetic slot wedge

A technology of turbogenerator and magnetic slot wedge, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of reducing generator efficiency, decreasing generator efficiency, increasing excitation loss, etc., and achieves the reduction of stator magnetic flux leakage The effect of increasing the flux, reducing the amplitude of the air gap harmonics, and reducing the eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

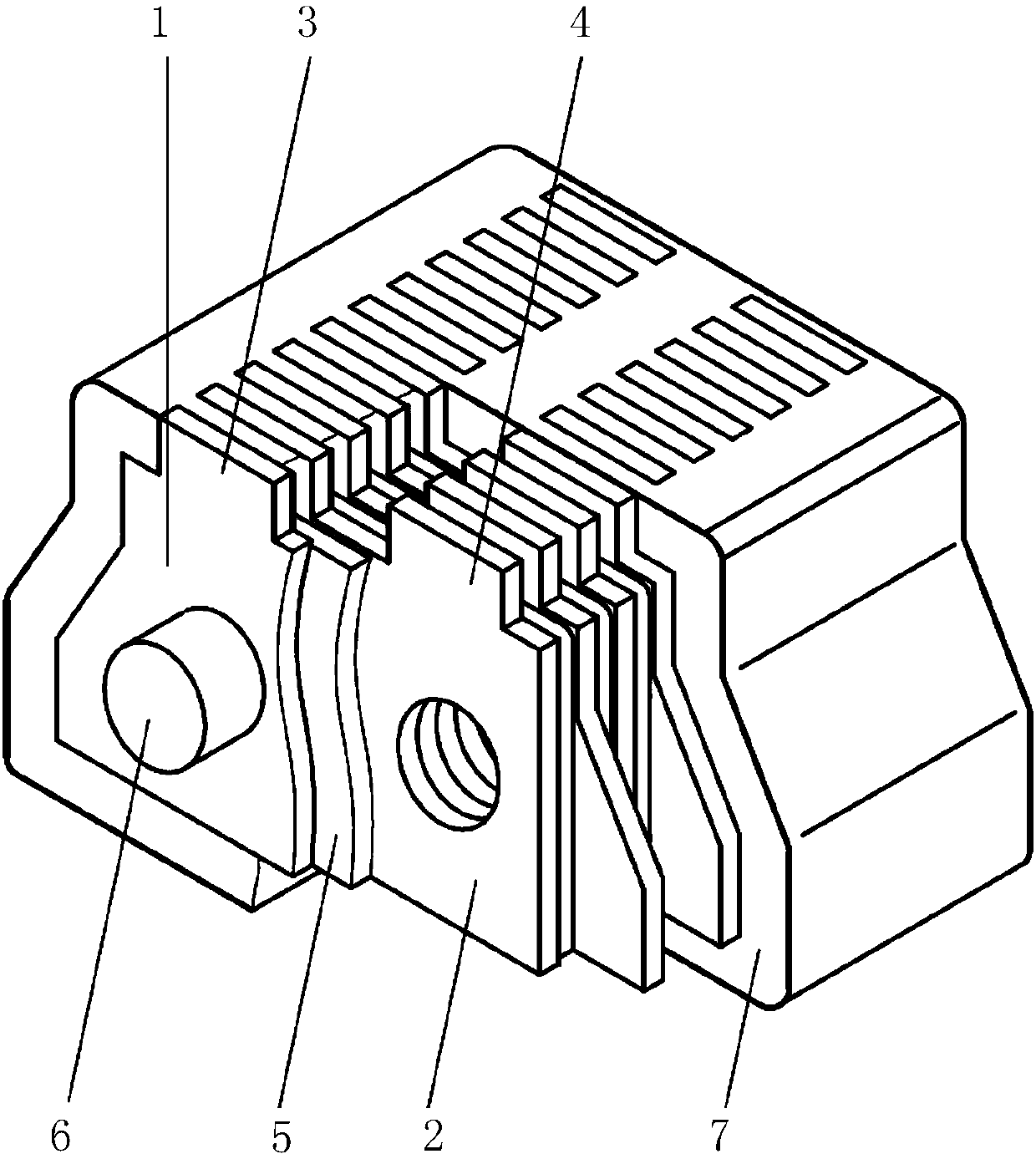

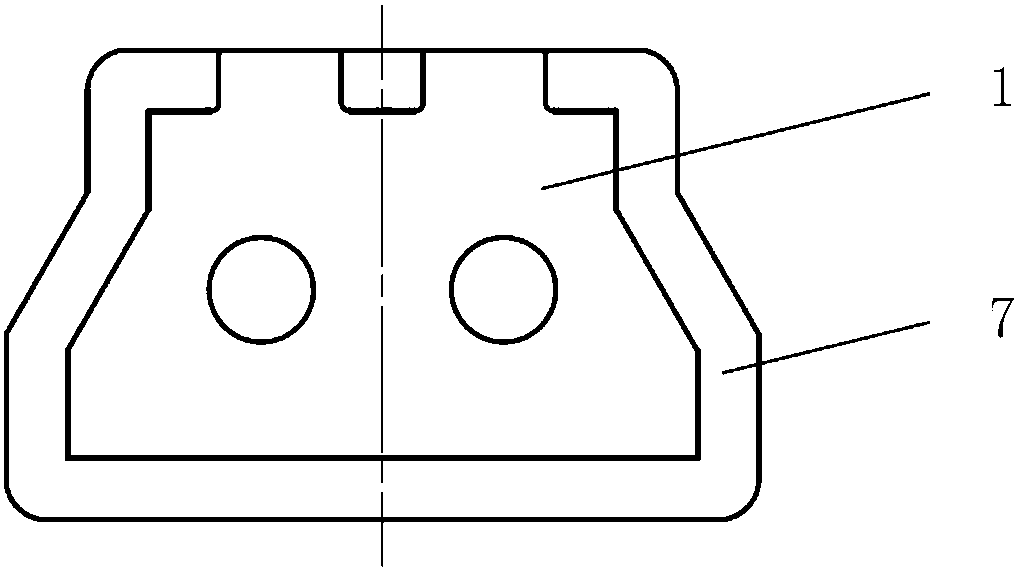

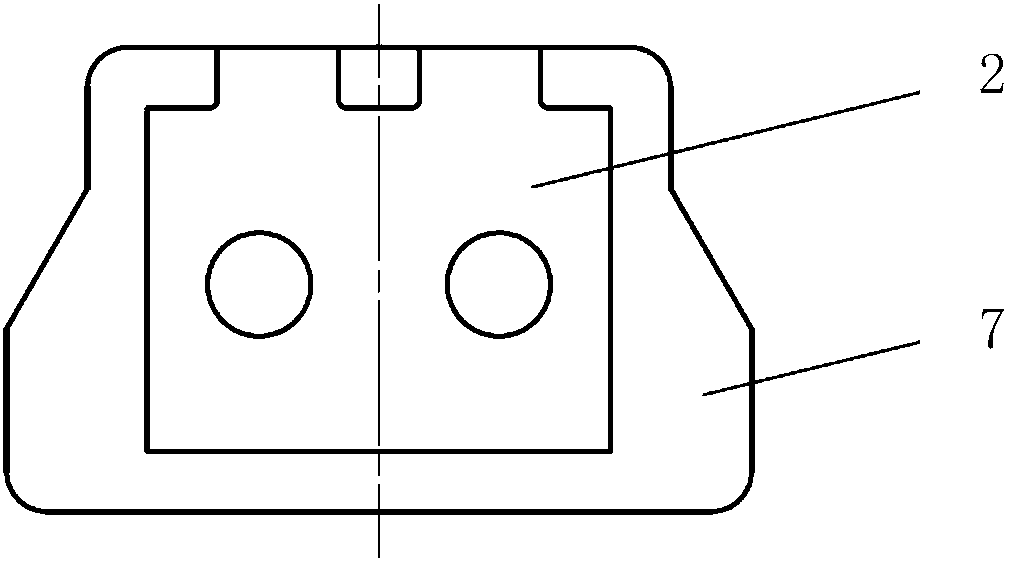

[0014] A magnetic slot wedge for a steam turbine generator, the magnetically conductive main body of the slot wedge is composed of a magnetically conductive sheet 1 with a first structure and a magnetically conductive sheet 2 with a second structure; the magnetically conductive sheet 1 with the first structure is punched from a silicon steel sheet, Its shape is the same as the section of the slot wedge, but its external dimensions are smaller than the section of the slot wedge, and the upper end has a first flange 3 exposed to the top surface of the slot wedge; the second structure of the magnetic sheet 2 is that the width dimension is smaller than the slot width and the height dimension is smaller than the slot wedge The rectangular structure of the wedge thickness has a second flange 4 exposed on the top surface of the slot wedge at the upper end. The magnetic permeable sheets 1 of the first structure and the magnetic permeable sheets 2 of the second structure are arranged alt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com