Heat insulation and dissipation device for motor

A heat dissipation device and heat insulation layer technology, applied in the field of medical equipment, can solve the problems of shortening the service life of motors, short service life, temperature rise, etc., and achieve the effect of expanding the application range, improving the heat dissipation effect, and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

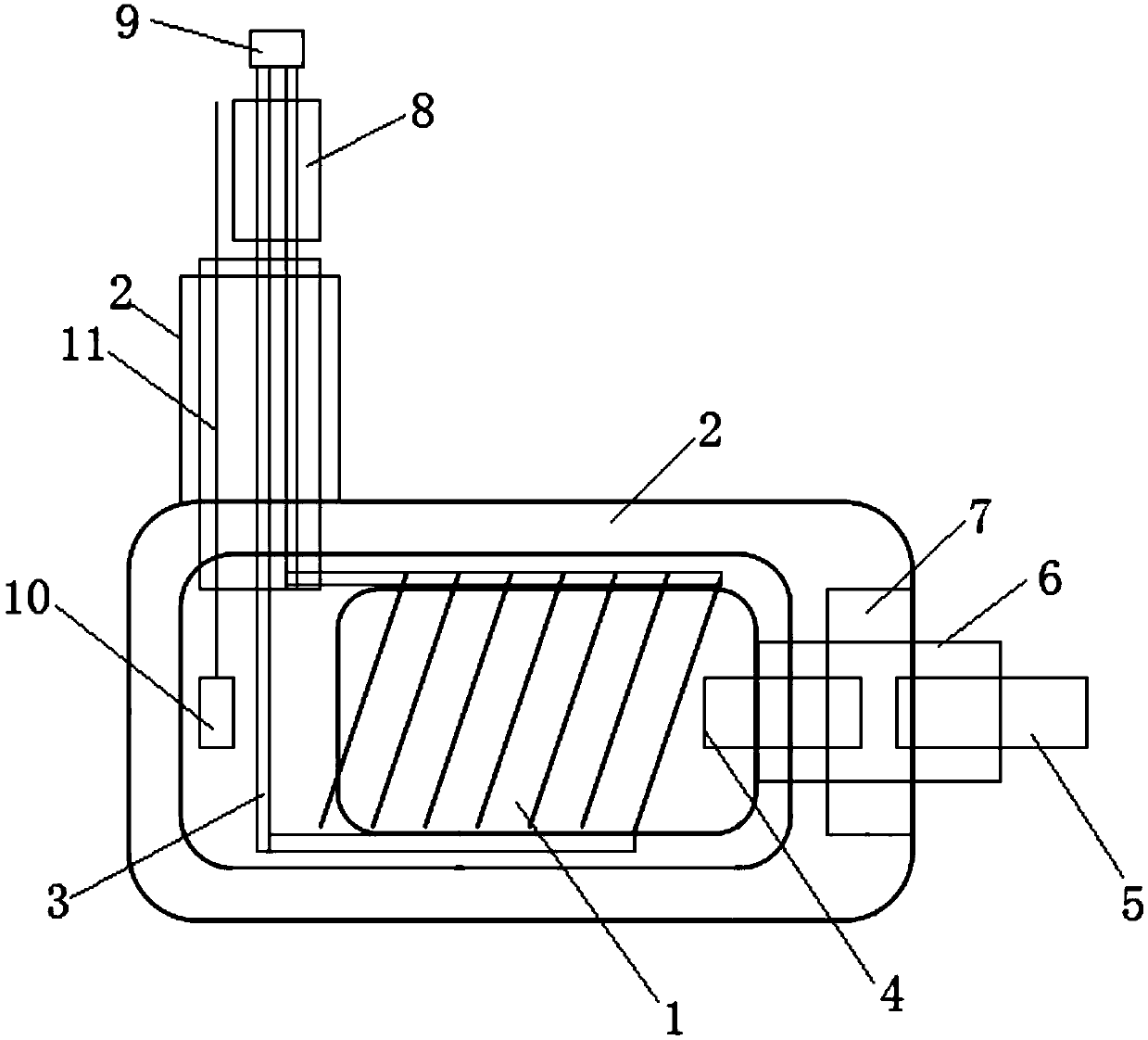

[0029] This embodiment provides a motor heat insulation and heat dissipation device, which is used to improve the heat insulation and heat dissipation performance of the motor, prevent the motor from malfunctioning due to high temperature, and prolong its service life. At the same time, the heat insulation effect of the device can isolate external heat Invading the motor, so that the motor can work normally in a high temperature environment, especially suitable for medical equipment in a dry heat sterilization environment, improving the automation of the equipment and reducing manual intervention.

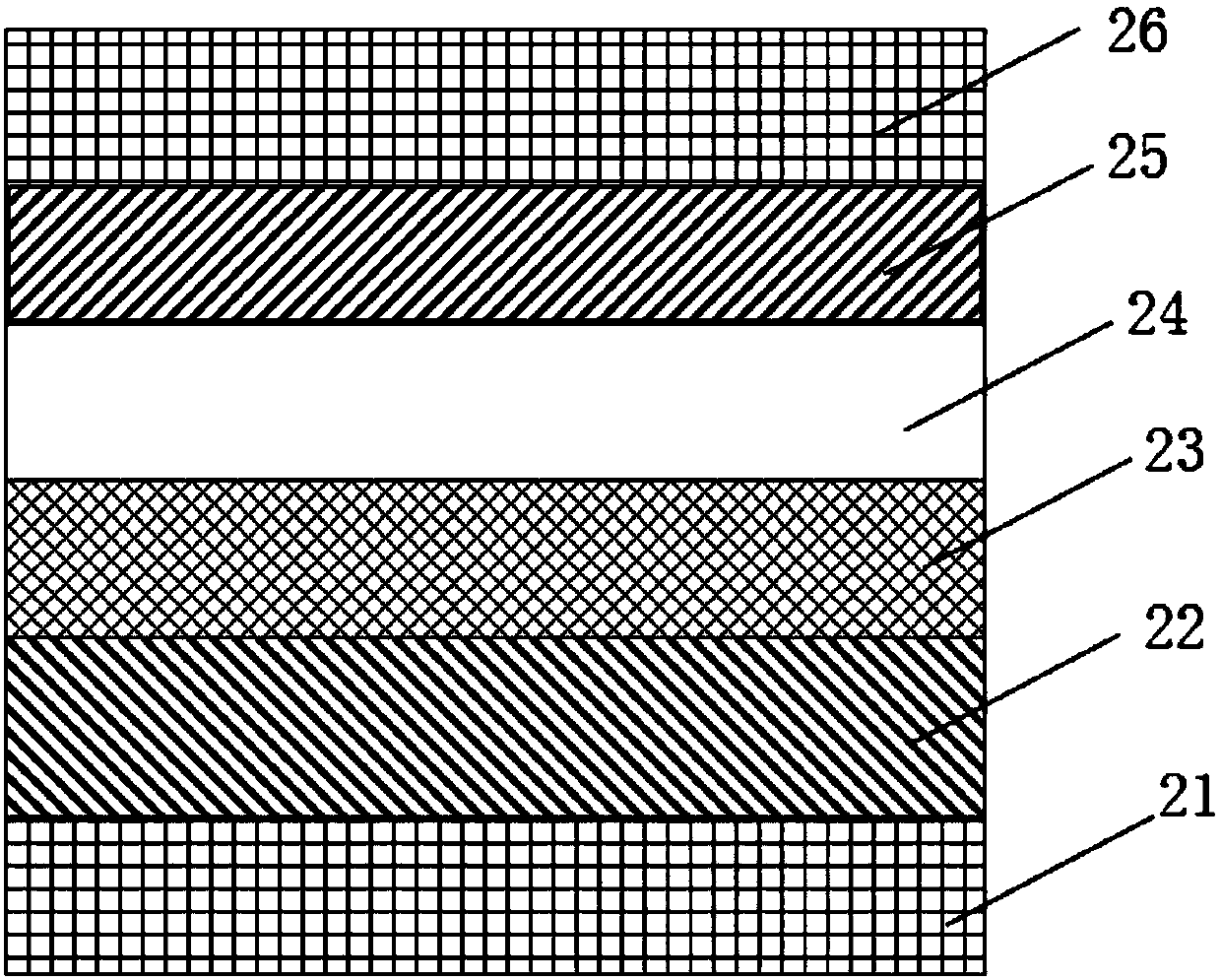

[0030] The motor heat insulation and heat dissipation device described in this embodiment, such as figure 1 As shown, the device includes a heat dissipation mechanism arranged outside the motor 1 for dissipating the heat generated by the motor, and also includes a heat insulation mechanism 2 wrapped outside the heat dissipation mechanism. Specifically, the heat dissipation mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com