Suspension damping system and washing machine

A technology for suspension shock absorption and washing machine, which is applied in the field of washing machines and can solve the problems of ineffective shock absorption and damping changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

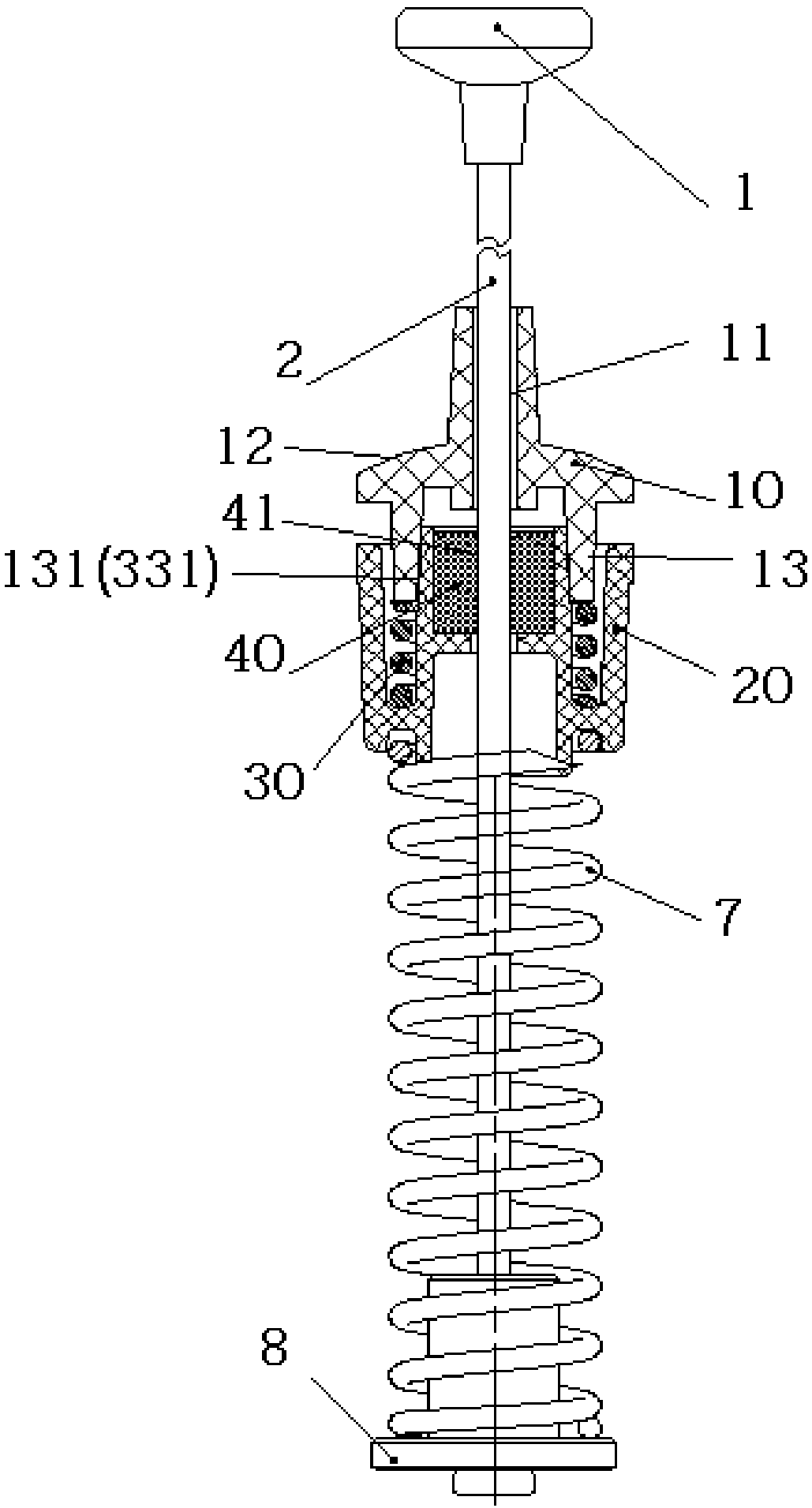

[0047] As an embodiment of the present invention, an abutment surface 1311 is at least partially formed on the inner peripheral surface 131 of the matching portion 13, and the abutment surface 1311 can be a curved surface or a plane surface, preferably where the abutment surface 1311 is located. The plane intersects the axis of the suspension rod 2 , and a mating surface 3311 corresponding to the abutting surface 1311 is formed on the outer peripheral surface 331 of the damping adjustment part 3 . For example, only part of the matching portion 13 is formed as an inclined surface. When the inclined surface moves downward, the axial force can also decompose the radial force. The pressure gets high. In addition, there can be multiple such inclined surfaces as the abutting surface 1311 , which are evenly distributed along the circumferential direction. In addition, the inclined surfaces can be formed on the same tapered surface, or can be formed on different tapered surfaces.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com