EGR rate calculating method and system with low-pressure EGR system and vehicle

A calculation method and low-pressure technology, applied in the direction of fuel injection control, engine control, machine/engine, etc., can solve problems such as affecting fuel consumption and emissions, inability to know fresh air, and inability to accurately control fuel injection amount, etc. Precisely controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

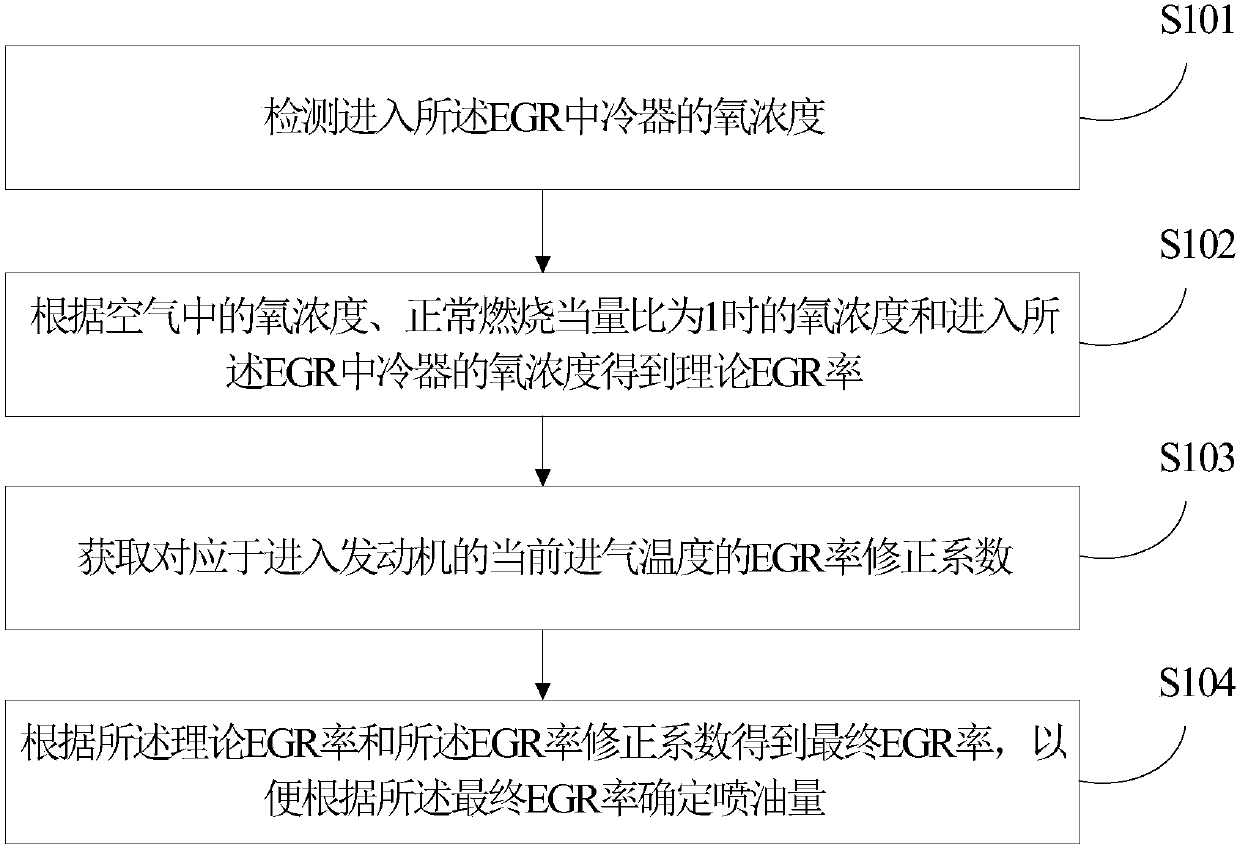

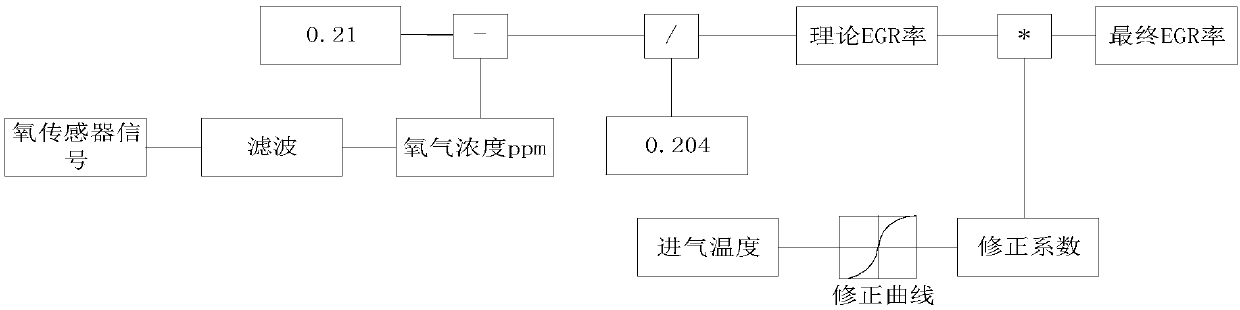

[0033] figure 2 is a flow chart of an EGR rate calculation method with a low-pressure EGR system according to an embodiment of the present invention.

[0034] Before describing the EGR rate calculation method with the low-pressure EGR system according to the embodiment of the present invention, the engine system will be explained first.

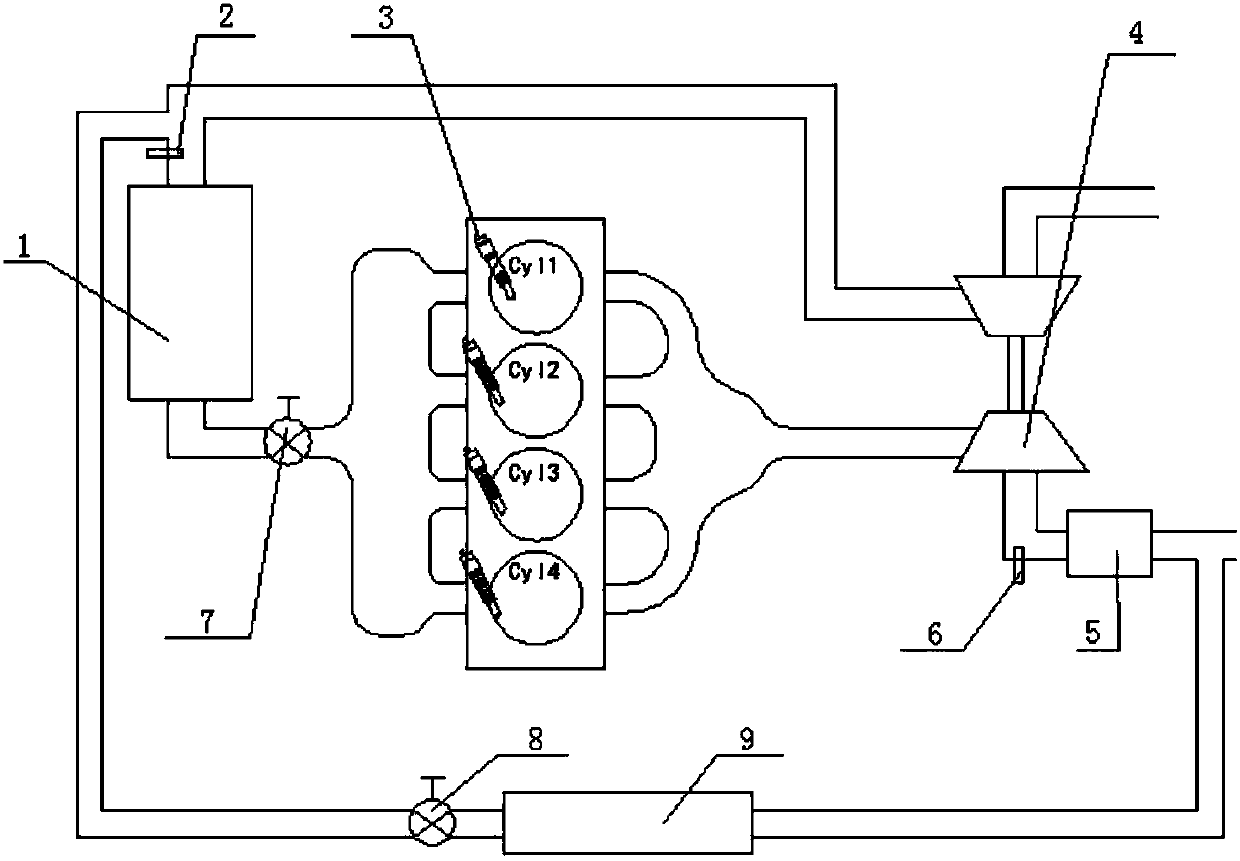

[0035] Such as figure 1 As shown, the engine system includes a low-pressure EGR system and other structures. The low-pressure EGR system includes a catalytic converter 5, an EGR cooler 9, an EGR valve 8, and an EGR intercooler 1 connected in series. The EGR intercooler 1 is connected to the intake side of the engine. The catalytic converter 5 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com