Collimating lens and automotive optical module

A technology of collimating lens and optical module, which is applied in the optical system field of matrix headlights, can solve the problems of cost increase and achieve the effect of unit cost reduction, increased strength and rigidity, and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

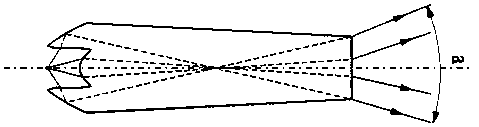

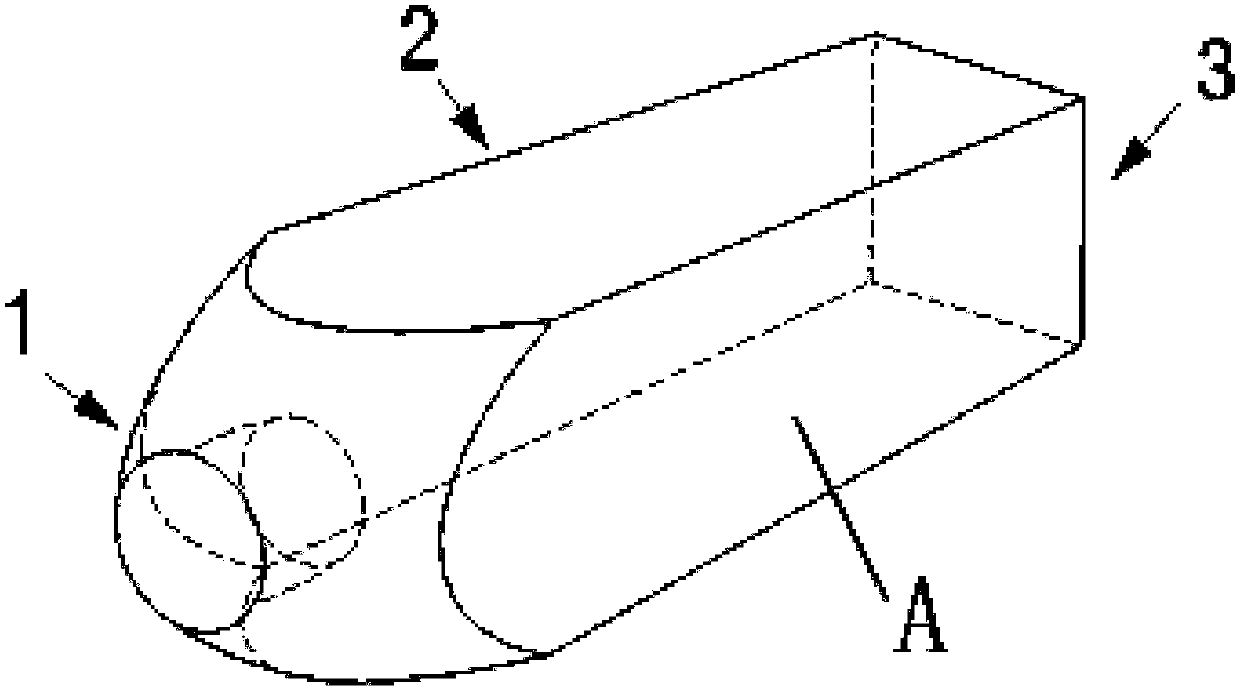

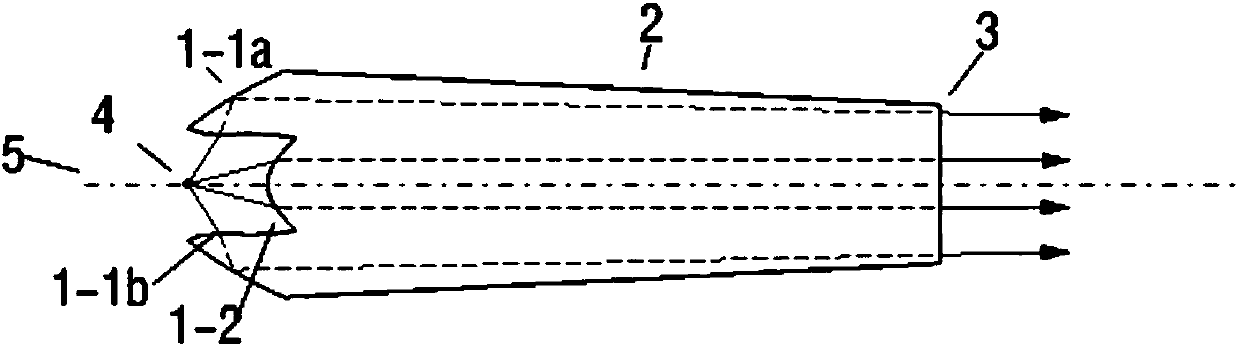

[0060] Such as figure 1 As shown, the present invention discloses a collimator lens, which is in the shape of a cone. The light-focusing end is a special-shaped structure that protrudes backward as a whole, is concave at the center, and the bottom surface of the depression protrudes backward. On the light emitting surface, the radially outermost surface 1-1a of the light concentrating end is a total reflection surface. The light-focusing end has a focal point, which is located on the optical axis 5, behind the bottom surface of the depression, and in an area close to the rear edge of the light-condensing end. The light emitted from the focal point can pass through the light-condensing end and exit the light-emitting surface parallelly and directly, or form a cross and exit the light-emitting surface at a certain angle. The focal point 4 is preferably a light source placement point. The surface other than the light-emitting surface and the light-concentrating end surface is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com