Aero-engine blisk annular cutter machining method based on control line

A technology of aero-engines and integral blisks, applied in the direction of manufacturing tools, metal processing equipment, milling machine equipment, etc., can solve the problems of low processing quality, complicated operation process, low efficiency, etc., to improve the processing surface quality, high efficiency, The effect of reducing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

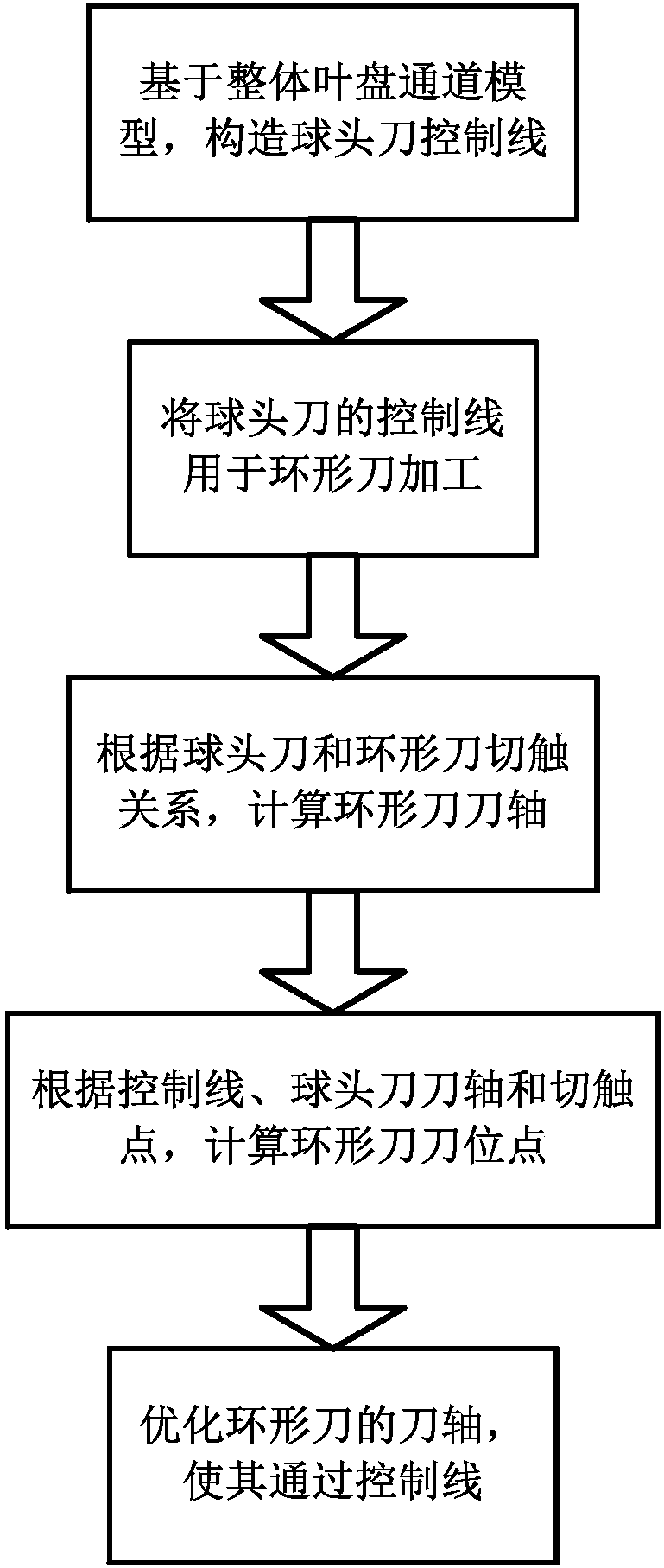

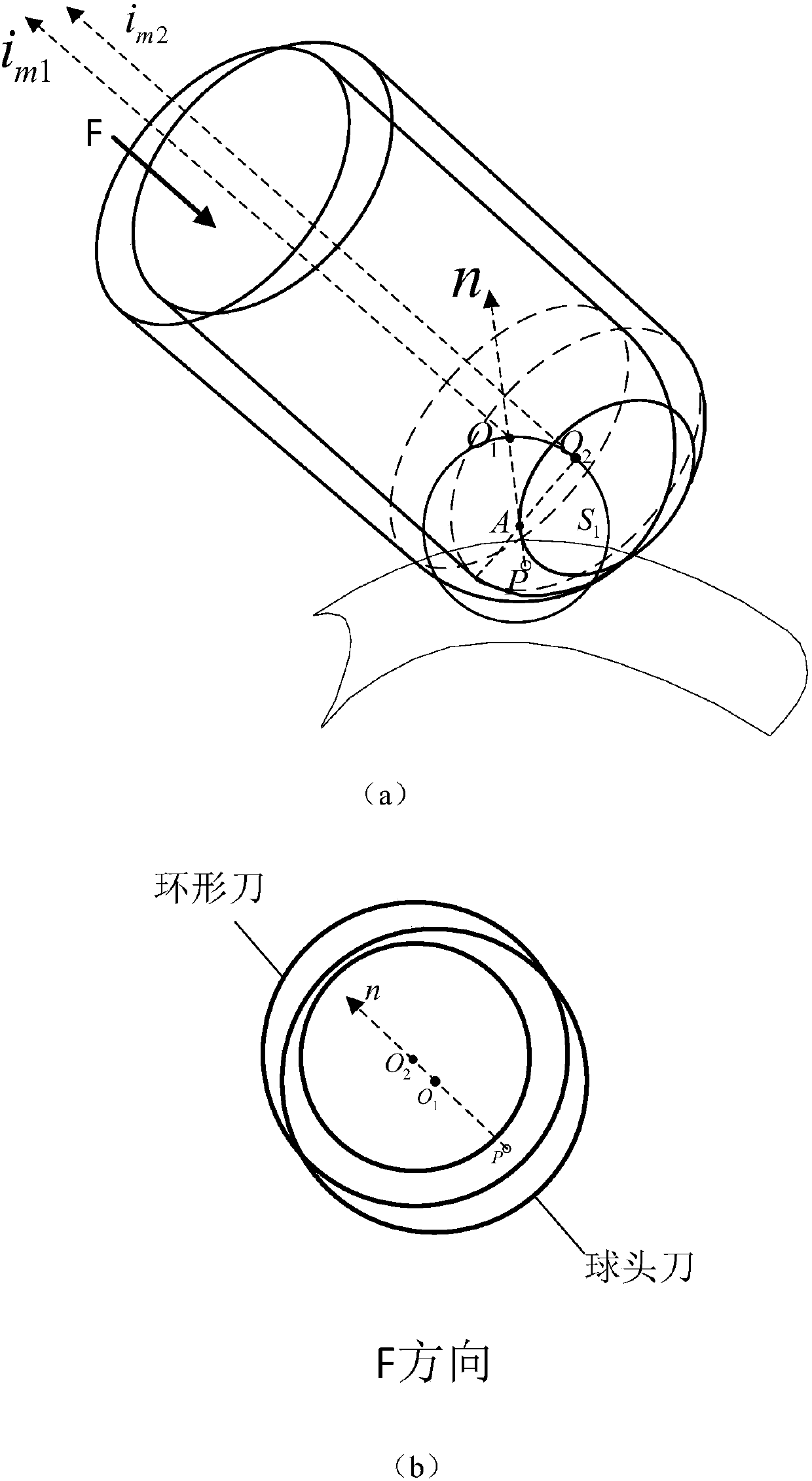

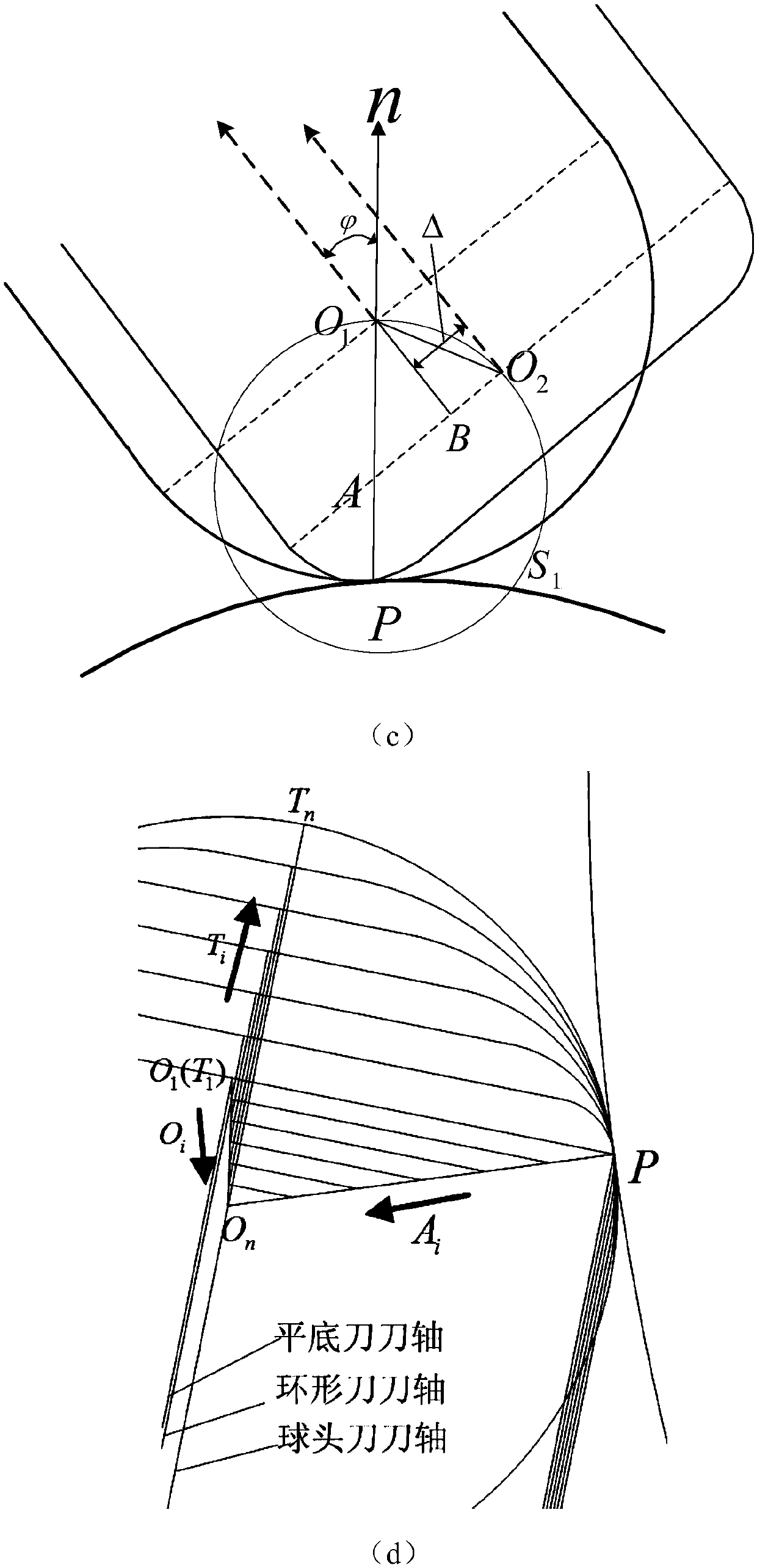

[0034] figure 1 It is the overall flow chart of the present invention. In channel processing, once the tool center point and the control line are determined, the cutter axis of the ball nose cutter is also determined immediately. The point connecting the tool center point and the control line is equal to its height direction. The shaft of the ball nose cutter. Now the ball-end cutter control line is used for ring cutter processing. Since the contact relationship between the ball-end cutter and the ring cutter is different, it is necessary to recalculate the cutter center point and the cutter axis of the ring cutter.

[0035] Step 1. According to the model of the blisk channel, construct the ball-end cutter non-interference cutter axis control line required for channel processing;

[0036] Step 2. Apply the control line of the ball head cutter to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com