Fitting polishing device and polishing method

A technology for polishing devices and accessories, applied in grinding/polishing safety devices, grinding drive devices, grinding/polishing equipment, etc., which can solve the problems of dust generation, limited use range, and only in places with power supply. , to avoid the accumulation of dust, reduce the risk of injury, and improve the quality of polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

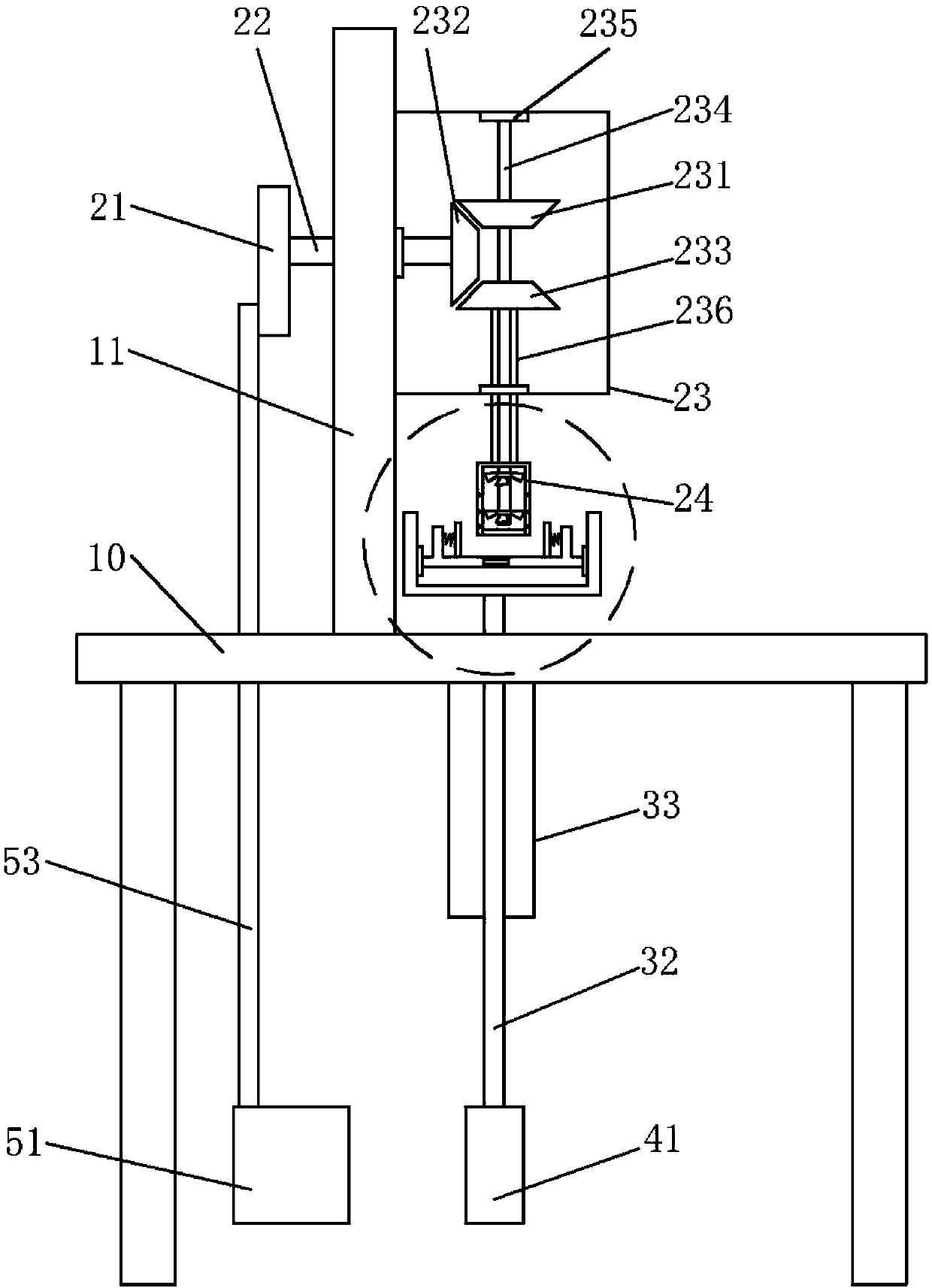

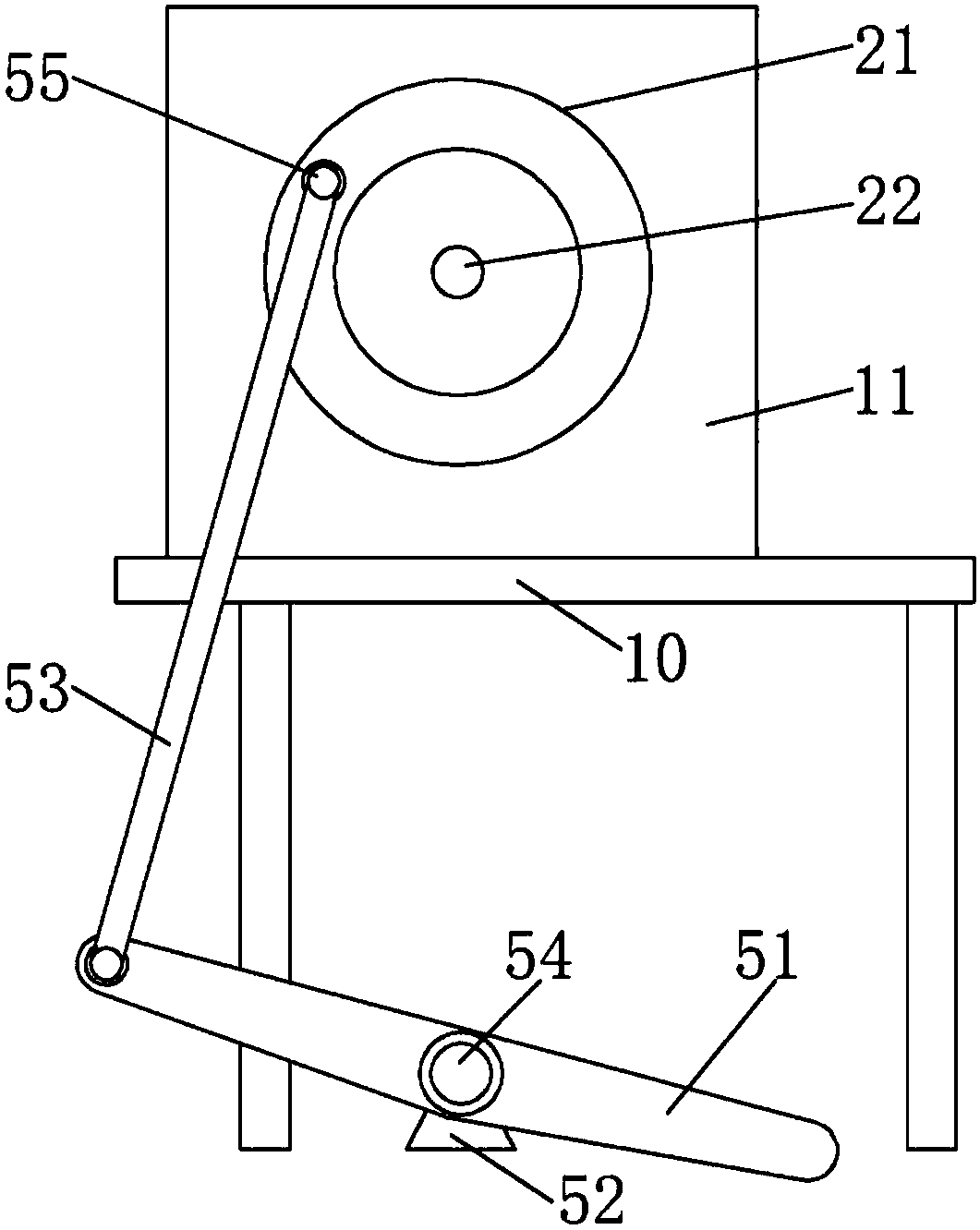

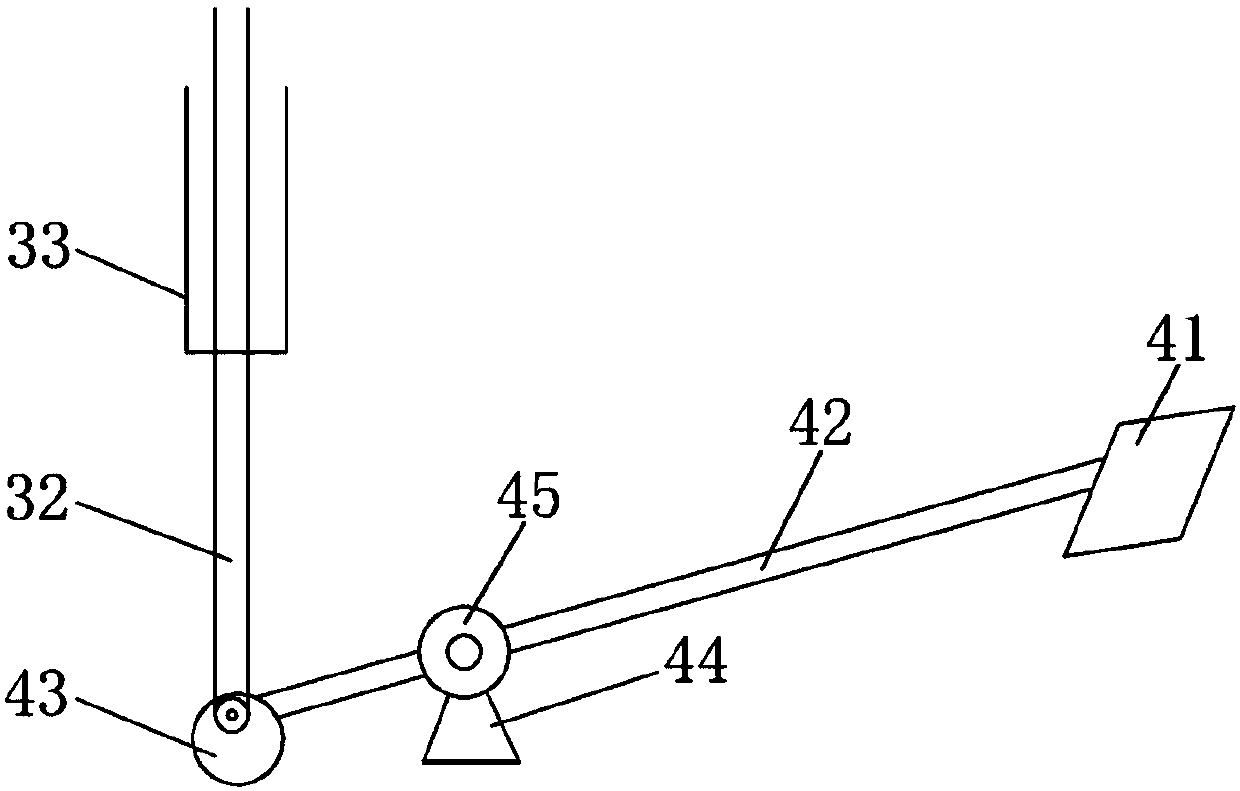

[0020] see Figure 1 to Figure 5 , an accessory polishing device according to the present invention includes a workbench 10 , a polishing mechanism and a positioning mechanism, and a vertical plate 11 is installed on the top surface of the workbench 10 .

[0021] The polishing mechanism includes a driving wheel 21 , a driving mechanism for driving the driving wheel 21 to rotate, a driving shaft 22 , a gear box 23 and a polishing cylinder 24 . The vertical plate 11 is provided with a first shaft hole, and the driving shaft 22 is arranged laterally. The driving shaft 22 is rotatably passed through the first shaft hole through the first bearing member. The driving wheel 21 is arranged on one side of the vertical plate 11 , and the center of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com