An assembled guard plate applied to a shot blasting machine

A technology of shot blasting machine and guard plate, which is applied to used abrasive processing devices, metal processing equipment, manufacturing tools, etc., and can solve structural toughness, corrosion resistance, poor wear resistance, short service life, and easy to fall off, etc. problems, to achieve excellent corrosion resistance and wear resistance, improve strength, and ensure high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

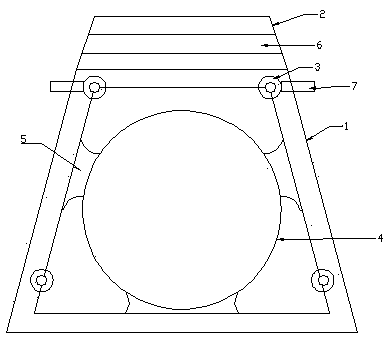

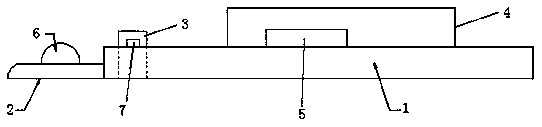

[0016] Such as figure 1 and figure 2 The shown assembly guard plate applied to the shot blasting machine includes a trapezoidal body 1, a trapezoidal auxiliary positioning plate 2 arranged at one end of the trapezoidal body 1, and two sets of positioning holes 3 symmetrically arranged on the trapezoidal body 1, and The limit sleeve 4 arranged on the trapezoidal body 1, and the three reinforcing ribs 5 connected with the limit sleeve 4 and the trapezoidal body 1 respectively, and the semicircular sealing positioning protrusion 6 arranged on the trapezoidal auxiliary positioning plate 2; Body 1, trapezoidal auxiliary positioning plate 2, positioning hole 3, limit sleeve 4, three reinforcing ribs 5 and semicircular sealing positioning protrusion 6 are integrally formed stainless steel structures.

[0017] Further preferably, the assembly guard plate applied to the shot blasting machine also includes rectangular auxiliary limit plates 7 respectively arranged on the trapezoidal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com