A quick slicing device for navel orange

A slicing device and fast technology, applied in metal processing and other directions, can solve the problems of low work efficiency, complicated operation, and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

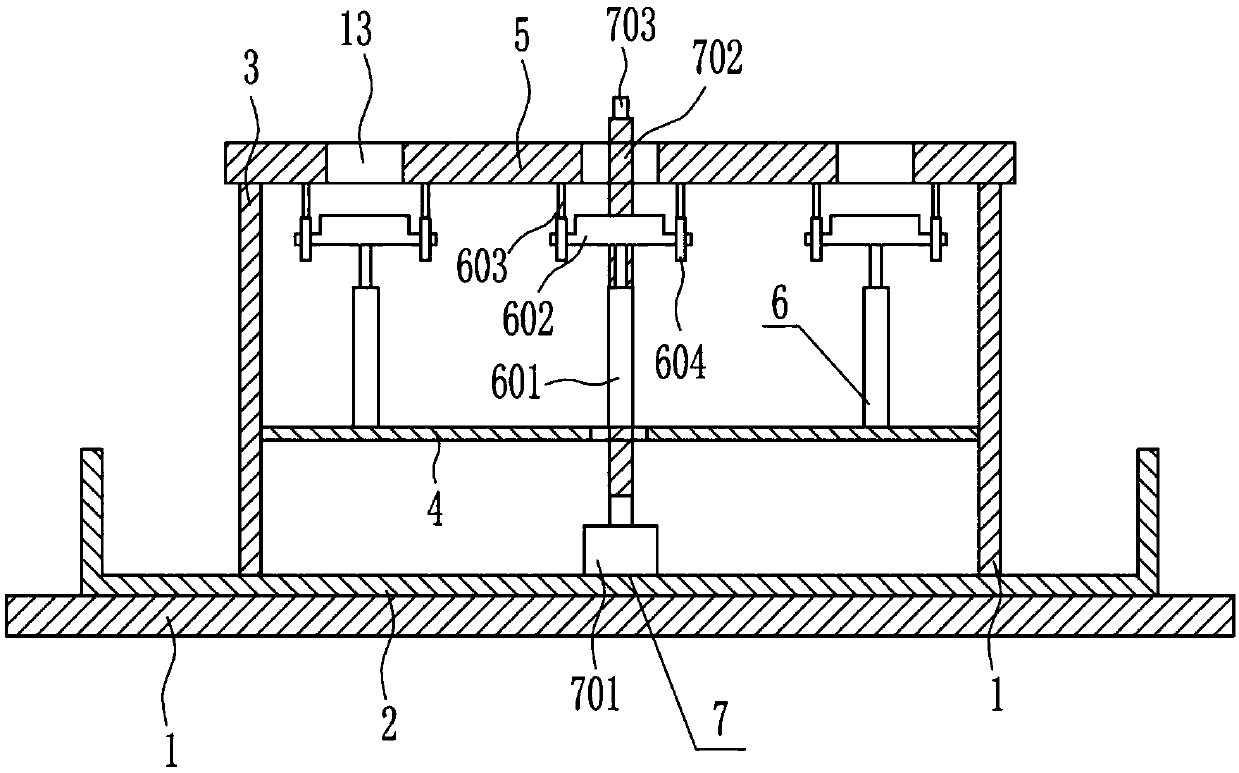

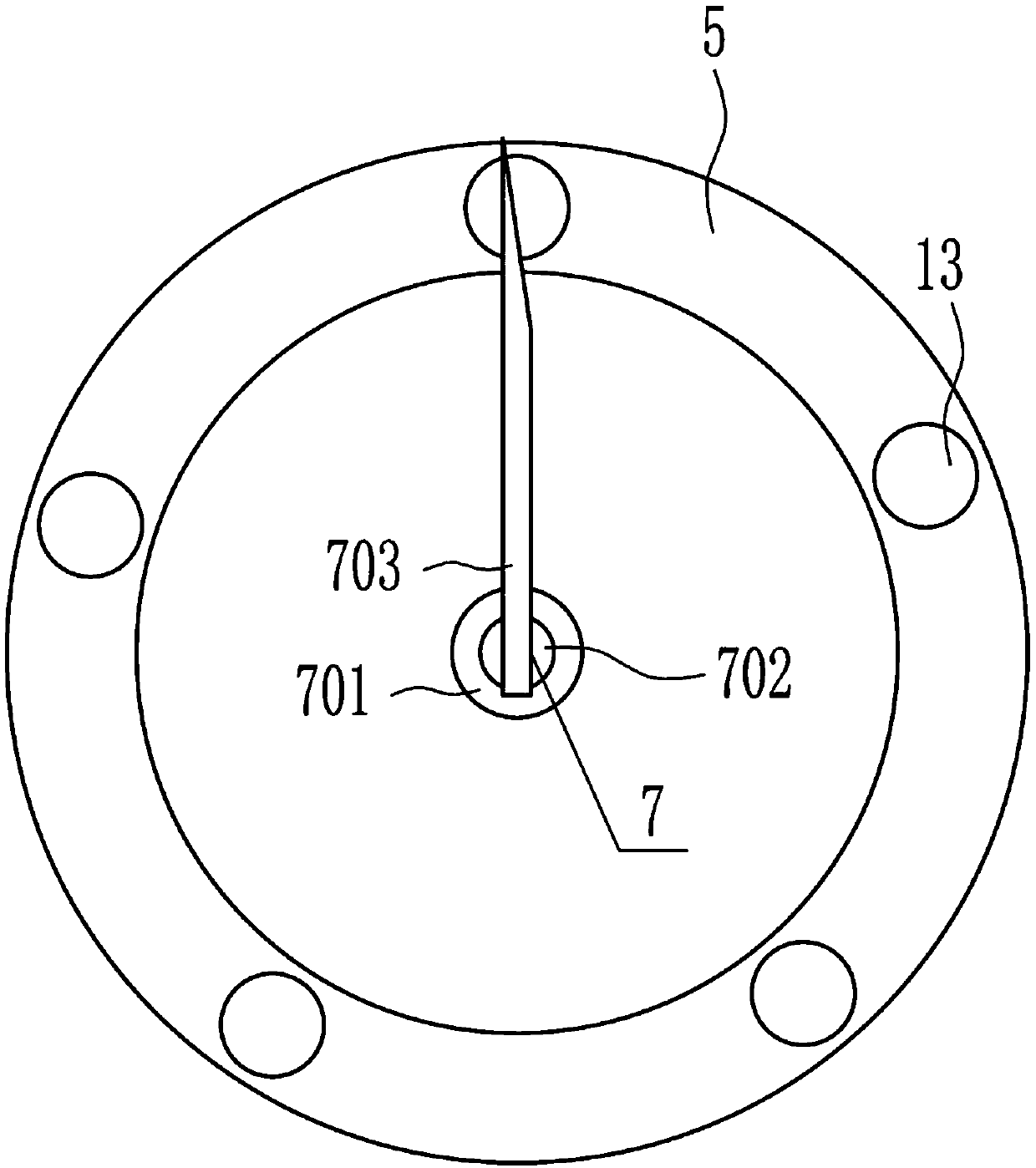

[0037] A navel orange fast slicing device, such as Figure 1-7 As shown, it includes a base plate 1, a collection frame 2, a barrel body 3, a circular plate 4, a disc 5, a placement device 6 and a slicing device 7. The top of the bottom plate 1 is welded with a collection frame 2, and the top of the collection frame 2 is welded with a barrel body 3. Discs 5 are welded on the top of the barrel body 3, and placement grooves 13 are evenly spaced around the circumferential direction on the discs 5, and a circular plate 4 is welded horizontally on the lower part of the barrel body 3, and the top of the disc 4 is provided with placement slots around the circumferential direction. Device 6, the placement device 6 is positioned directly below the placement groove 13, a slicing device 7 is arranged in the middle of the top of the collection frame, the slicing device 7 is located in the barrel body 3, the top of the slicing device 7 is positioned above the disk 5, and the top of the slic...

Embodiment 2

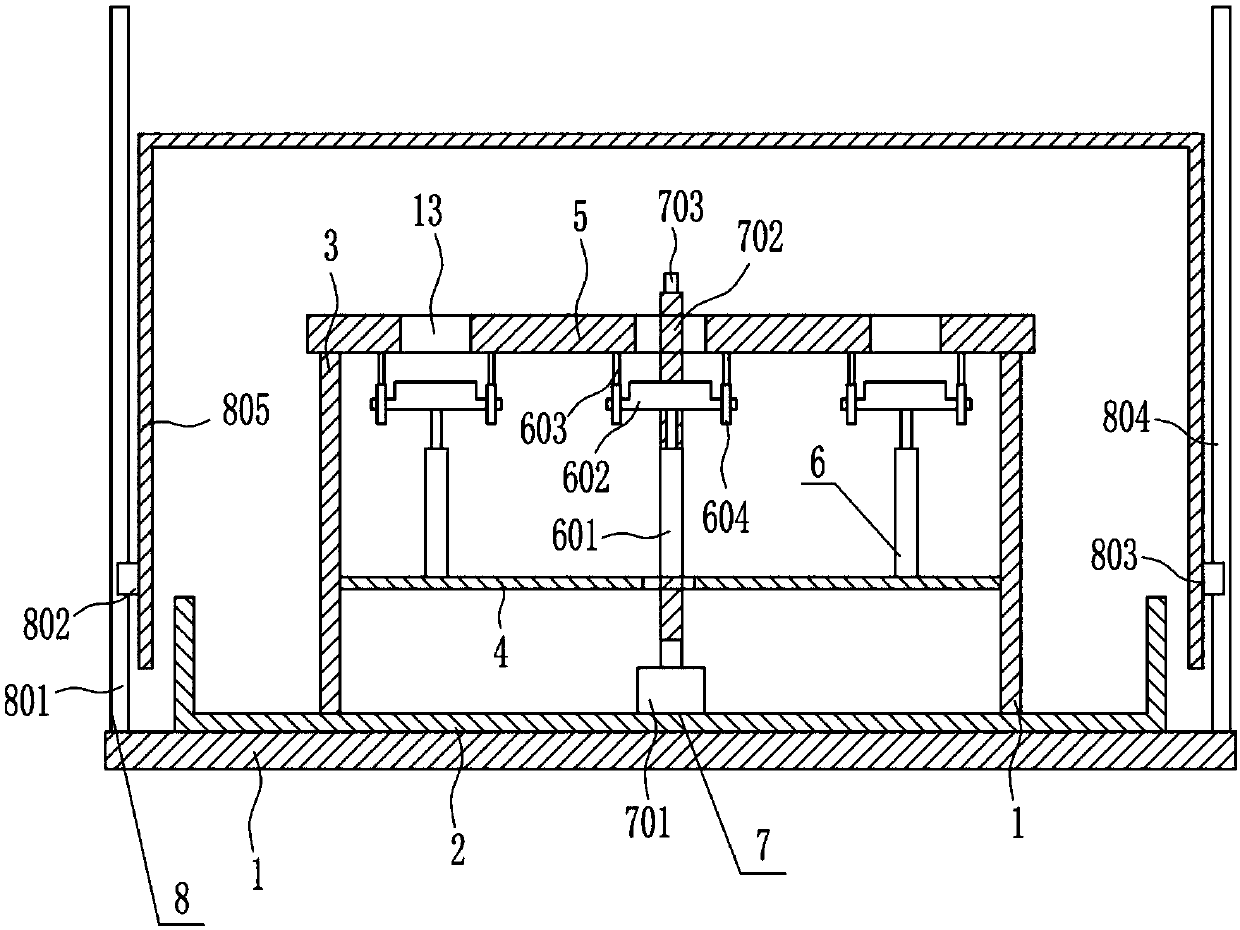

[0039] A navel orange fast slicing device, such as Figure 1-7 As shown, it includes a base plate 1, a collection frame 2, a barrel body 3, a circular plate 4, a disc 5, a placement device 6 and a slicing device 7. The top of the bottom plate 1 is welded with a collection frame 2, and the top of the collection frame 2 is welded with a barrel body 3. Discs 5 are welded on the top of the barrel body 3, and placement grooves 13 are evenly spaced around the circumferential direction on the discs 5, and a circular plate 4 is welded horizontally on the lower part of the barrel body 3, and the top of the disc 4 is provided with placement slots around the circumferential direction. Device 6, the placement device 6 is positioned directly below the placement groove 13, a slicing device 7 is arranged in the middle of the top of the collection frame, the slicing device 7 is located in the barrel body 3, the top of the slicing device 7 is positioned above the disk 5, and the top of the slic...

Embodiment 3

[0042] A navel orange fast slicing device, such as Figure 1-7 As shown, it includes a base plate 1, a collection frame 2, a barrel body 3, a circular plate 4, a disc 5, a placement device 6 and a slicing device 7. The top of the bottom plate 1 is welded with a collection frame 2, and the top of the collection frame 2 is welded with a barrel body 3. Discs 5 are welded on the top of the barrel body 3, and placement grooves 13 are evenly spaced around the circumferential direction on the discs 5, and a circular plate 4 is welded horizontally on the lower part of the barrel body 3, and the top of the disc 4 is provided with placement slots around the circumferential direction. Device 6, the placement device 6 is positioned directly below the placement groove 13, a slicing device 7 is arranged in the middle of the top of the collection frame, the slicing device 7 is located in the barrel body 3, the top of the slicing device 7 is positioned above the disk 5, and the top of the slic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com