Concrete processing device for construction site

A technology for construction sites and processing devices, which is applied to clay preparation devices, mixing operation control devices, unloading devices, etc. Use, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

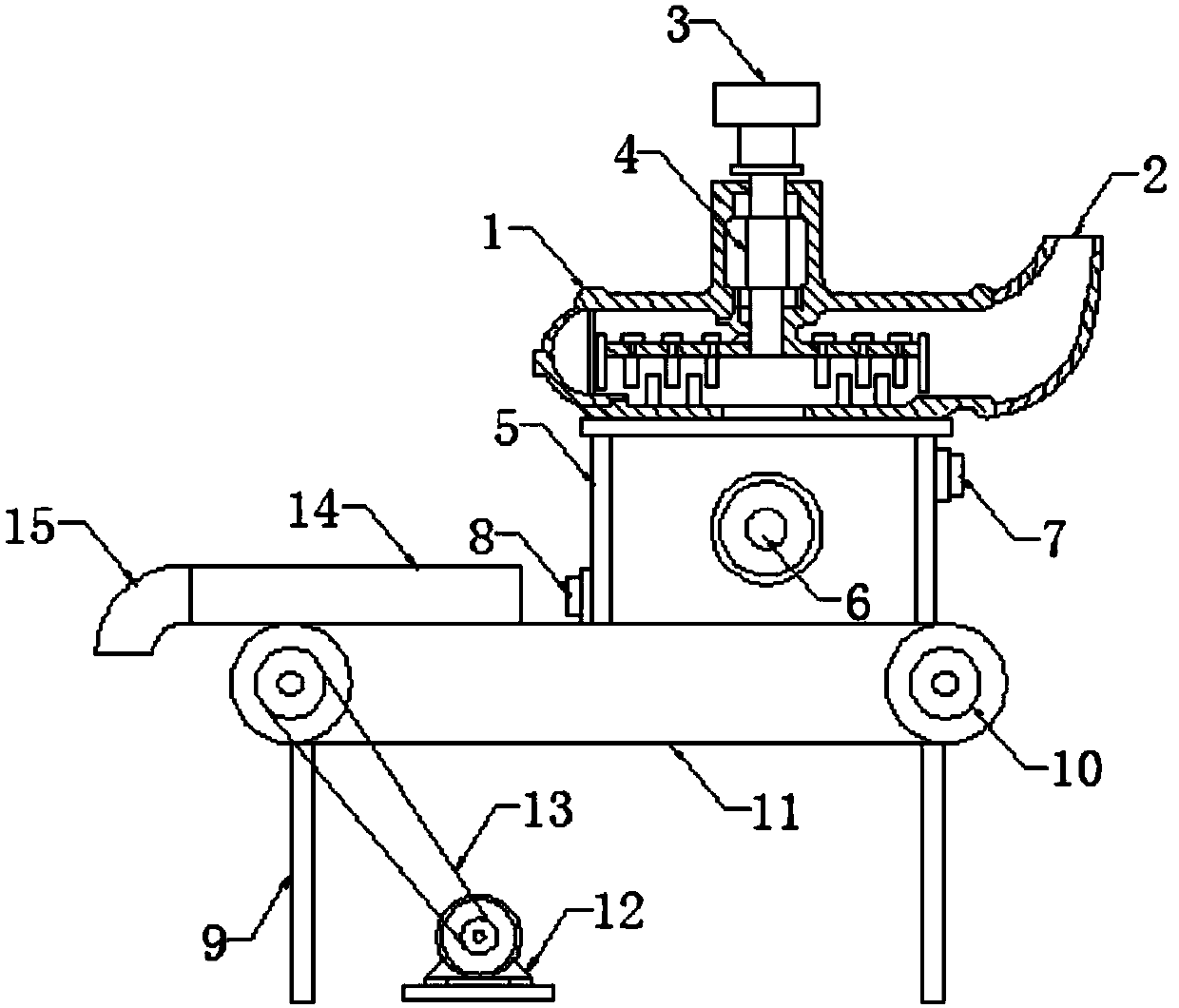

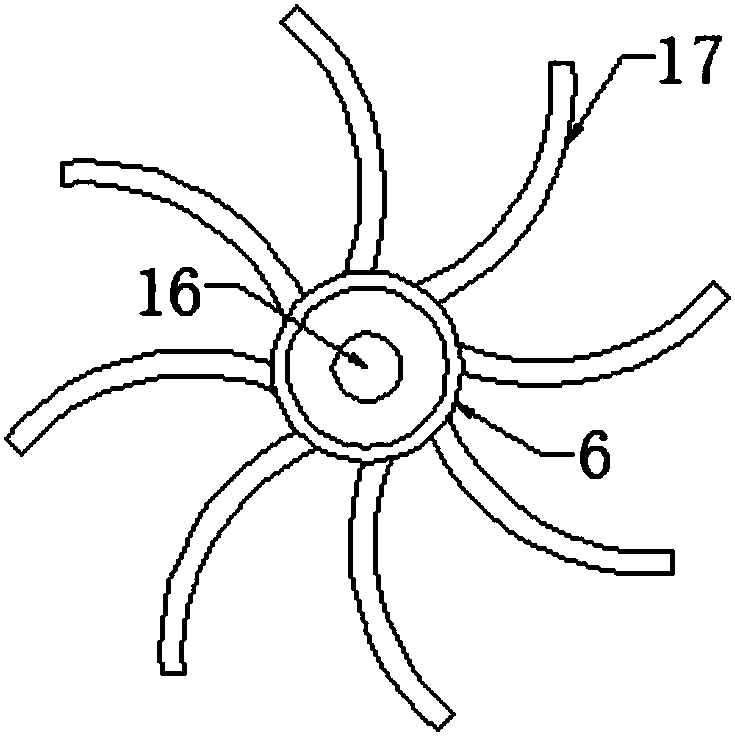

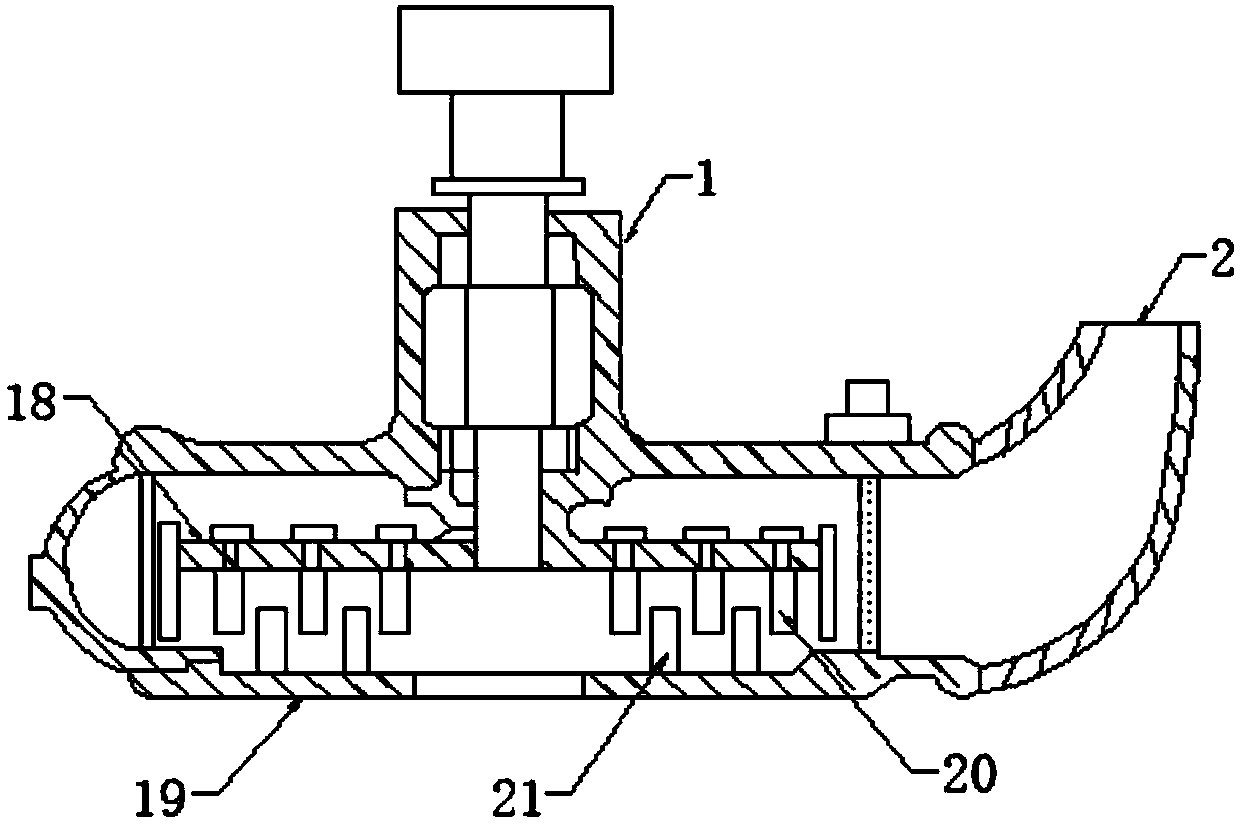

[0021] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a concrete processing device for a construction site, including a crushing tank 1, a feed port 2, a driving motor 3, a main shaft 4, a reaction box 5, a rotating motor 6, and a liquid inlet 7 , discharge port 8, frame 9, transmission wheel 10, conveyor belt 11, transmission motor 12, transmission belt 13, discharge baffle 14, discharge hopper 15, turning shaft 16, turning fan blade 17, moving grinding disc 18, fixed grinding disc 19. The movable tooth block 20 and the fixed tooth block 21, one end of the crushing tank 1 is provided with a feed port 2, and the feed port 2 communicates with the inner cavity of the crushing tank 1, and the drive motor 3 is fixedly installed on the crushing tank 1, and the drive motor 3 The output end is fixedly connected with the main shaft 4 in the crushing tank 1, the end of the main shaft 4 is fixedly connected with the movable grinding disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com