A device for continuous casting of epoxy resin-based composite material boards

A composite material board and epoxy resin technology, which is applied to the equipment for continuous casting of epoxy resin matrix composite material board and the field of composite material production equipment, can solve the problem of reducing product service life, affecting product appearance and performance, product bubbles, etc. problems, to achieve the effect of ensuring product quality, easy coating of sheets, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

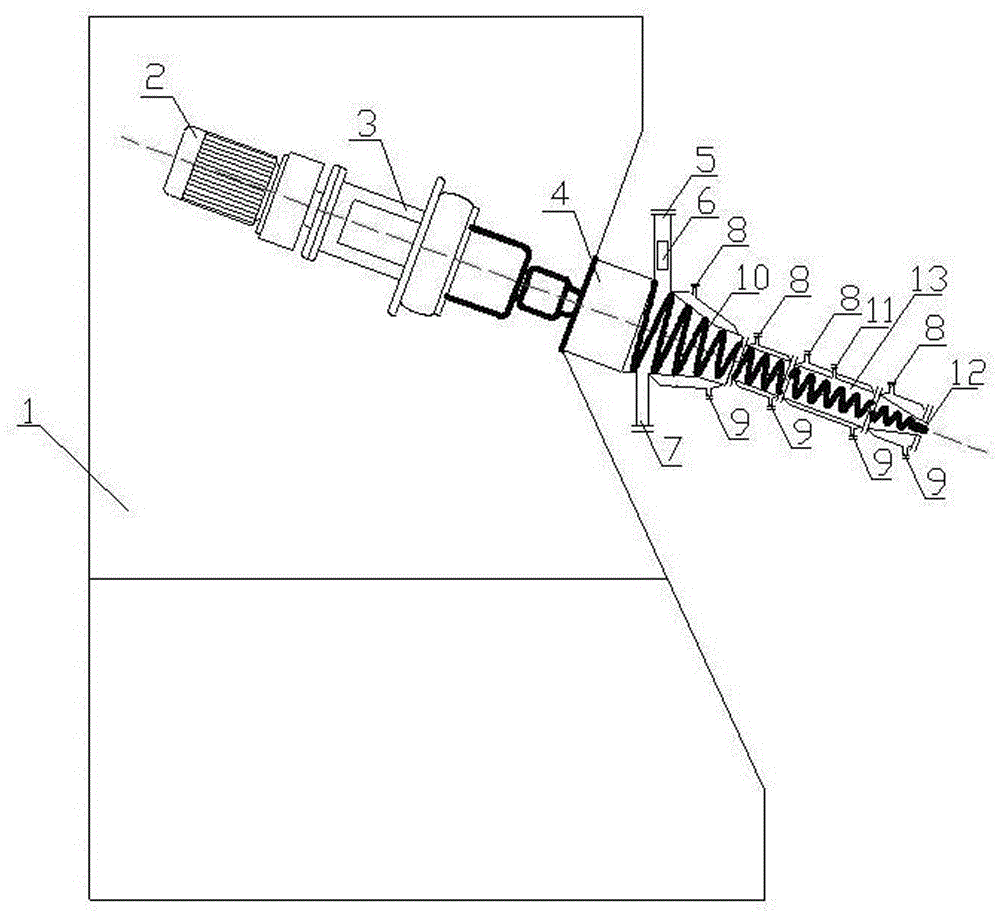

[0015] The device for continuously casting epoxy resin-based composite material plates includes a box body 1, a variable speed motor 2, a reducer 3, and a discharge pipe 13. The variable speed motor 2 is connected to the reducer 3, and its characteristic is that the discharge pipe 13 is a hollow cone. body, the top of the cone is the discharge port 12, the bottom of the cone is connected to the reducer 3 through the mechanical seal 4 and the bearing, and the screw rod 10 is installed inside the discharge pipe 13, and the diameter of the screw rod 10 is from the bottom of the cone cavity to the discharge port 12 gradually becomes thinner; the lower end of the bottom of the discharge pipe 13 is provided with a feed port 7, the upper end of the bottom of the discharge pipe 13 has a vacuum pipeline 5, and the middle upper end of the discharge pipe 13 is equipped with a pipeline 11 for adding an accelerator; The outer wall of the discharge pipe 13 is a jacket layer, and the jacket l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com