A continuous cracking and rectifying device

A technology of rectification and rectification section, applied in the fields of fractionation, depolymerization to produce hydrocarbons, organic chemistry, etc., can solve the problems of low thermal conductivity, prone to polymerization, temperature rise, etc. The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

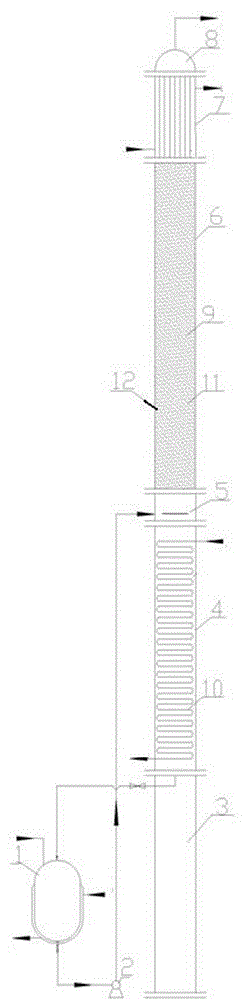

[0014] The cracking and rectifying device includes a preheating kettle 1, a gear pump 2, and a tower body 12. It is characterized in that: the preheating kettle 1 adopts a jacketed structure, and steam is introduced into the jacket, and one side of the preheating kettle 1 is connected to the The raw material supply tank is connected, and the raw material is continued to be added without stopping the pyrolysis and rectification. The other side of the preheating kettle 1 is connected with the gear pump 2; From bottom to top, there are respectively cracking section 4, rectifying section 6, and constant temperature section 7, and each section is connected to each other by flanges; distributor 5 is located between cracking section 4 and rectifying section 6, and distributor 5 is connected to gear pump 2 through pipelines The cracking section 4 pipeline is located on the base 3, higher than the preheating kettle 1, so that the liquid phase passing through the cracking section 4 can f...

Embodiment 2

[0017] The structure of the cracking and rectifying device is as in Example 1, and the specific dimensions of each part are as follows: the preheating tank 1 is 500 L, the head of the gear pump 2 is 20 m, the cracking section 4 is 4.5 m high, the tower body base 3 is 4 m high, and the rectifying section 6 The height is 6m, and the constant temperature section 7 is 1.5m high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com