Smart card with grating effect on surface and production method of smart card

A production method and technology for smart cards, which are applied in diffraction gratings, chemical instruments and methods, cards, etc., can solve the problems that the grating technology cannot be applied to smart cards, lack and other problems, and achieve the effect of vivid and dynamic surface images.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

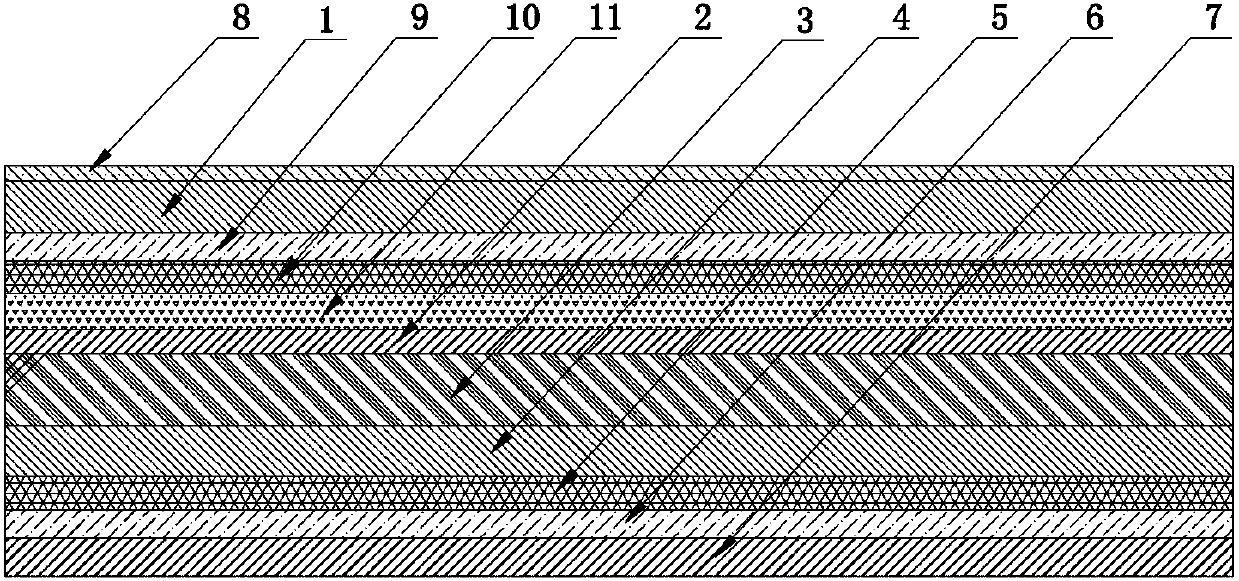

[0030] A smart card with a grating effect on the surface of this embodiment has a card base, and the card base sequentially includes a front PVC transparent substrate layer 1, a front PVC protective film layer 2, a middle INLAY layer 3, and a reverse PVC base layer. Sheet layer 4, back screen printing ink layer 5, back offset printing pattern layer 6, back PVC protective film layer 7, especially: the front side of described front PVC transparent substrate layer 1 has grating treatment layer 8, front PVC transparent substrate layer 1 Between the reverse side and the front PVC protective film layer 2, there are a front offset printing pattern layer 9, a front silk screen printing white ink layer 10, a front silk screen low temperature lamination adhesive layer 11, and the front silk screen low temperature lamination adhesive layer 11 is combined with the front PVC protective film layer 2.

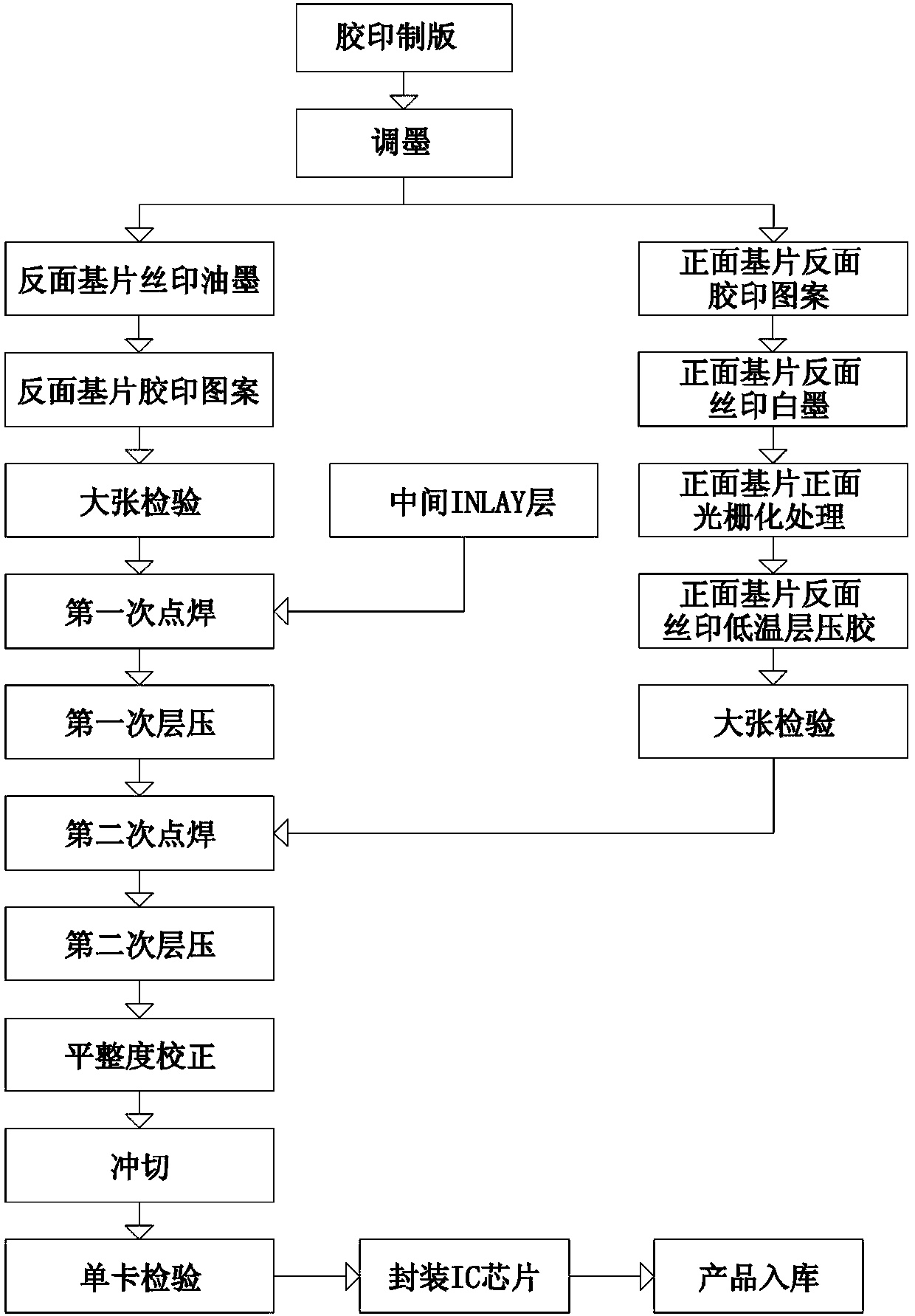

[0031] A method for producing a smart card with a grating effect on the surface of this em...

Embodiment 2

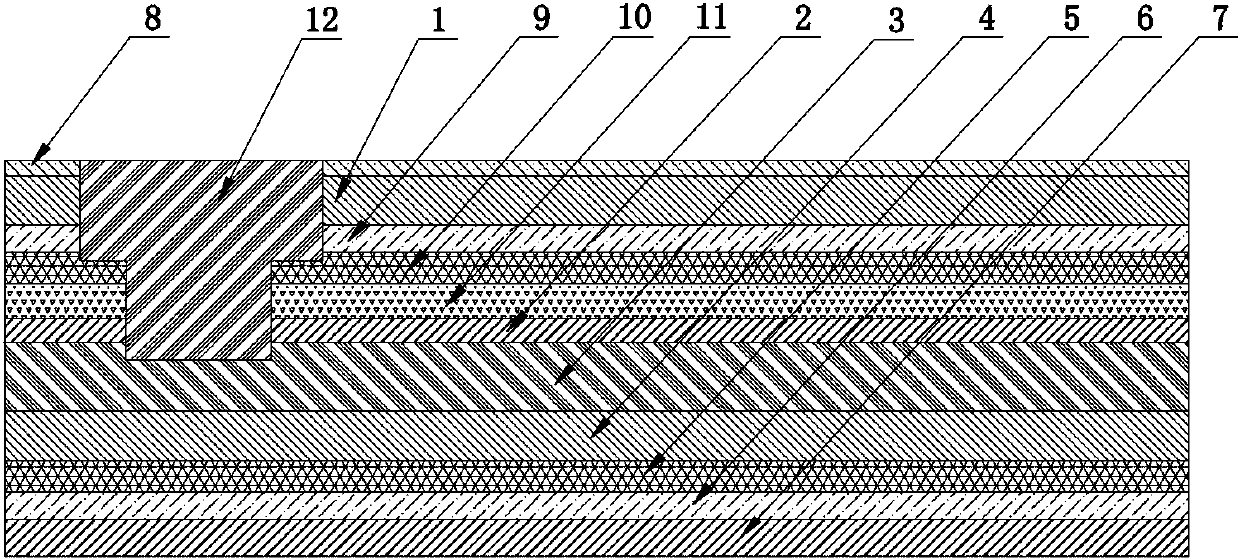

[0041] A smart card with a grating effect on the surface of this embodiment has a card base, and the card base sequentially includes a front PVC transparent substrate layer 1, a front PVC protective film layer 2, a middle INLAY layer 3, and a reverse PVC base layer. Sheet layer 4, back screen printing ink layer 5, back offset printing pattern layer 6, back PVC protective film layer 7, especially: the front side of described front PVC transparent substrate layer 1 has grating treatment layer 8, front PVC transparent substrate layer 1 Between the reverse side and the front PVC protective film layer 2, there is a front offset printing pattern layer 9, a front silk screen printing white ink layer 10, a front silk screen low temperature lamination adhesive layer 11, and the front silk screen low temperature lamination adhesive layer 11 is combined with the front PVC protective film layer 2, The front of the smart card base is also processed with a concave cavity 13 for accommodating...

Embodiment 3

[0051] A kind of smart card with a grating effect on the surface of this embodiment has the same structure as that of Embodiment 2, and its production method comprises the following steps:

[0052] (1) Take the large-sheet PVC substrate on the reverse side, and print the screen printing ink layer and the offset printing pattern layer on the front side of the PVC substrate on the reverse side according to the design graphic requirements, and carry out large-sheet inspection after printing is completed, and reserve;

[0053] (2) Take the large transparent PVC substrate on the front, and print the offset printing pattern layer and the white masking ink layer for silk screen printing on the reverse side of the large transparent PVC substrate according to the design graphic requirements. After printing, the transparent PVC substrate on the front The front of the substrate is rasterized. After the raster processing is completed, a low-temperature lamination adhesive layer is screen-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com