Glass containing fine crystal silver coating for adjusting gIR and manufacturing method thereof

A technology of silver coating and crystalline silver layer, applied in the direction of coating, etc., can solve the problems of low-emissivity glass that cannot be heat treated, the Ag layer is easily oxidized, and hinders the application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

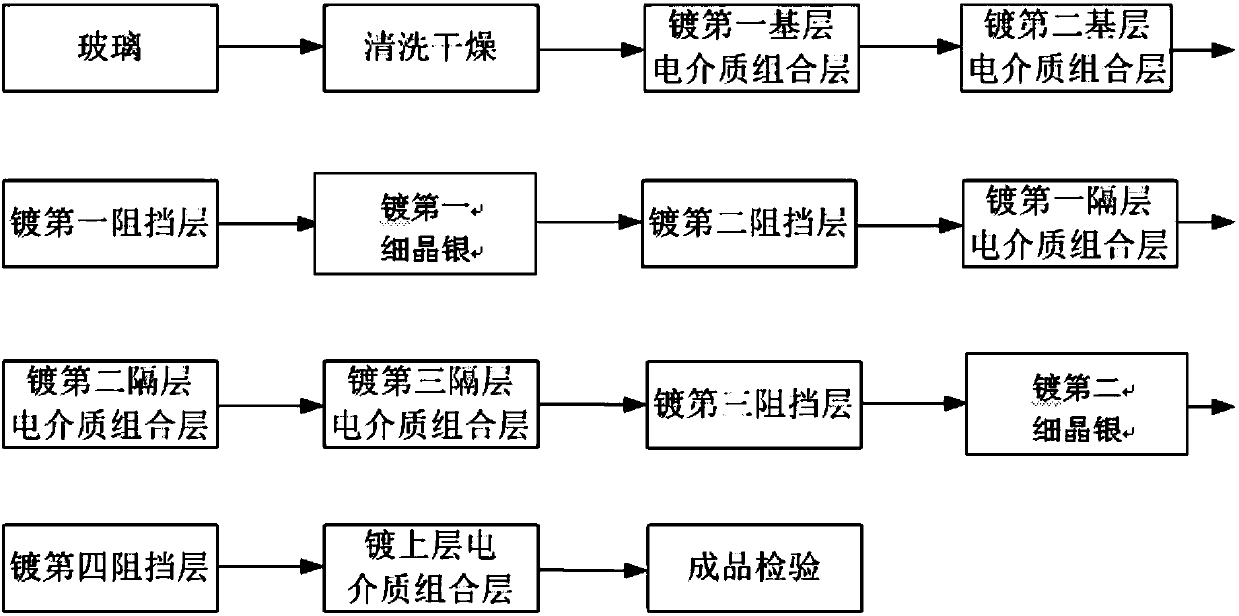

Method used

Image

Examples

Embodiment 1

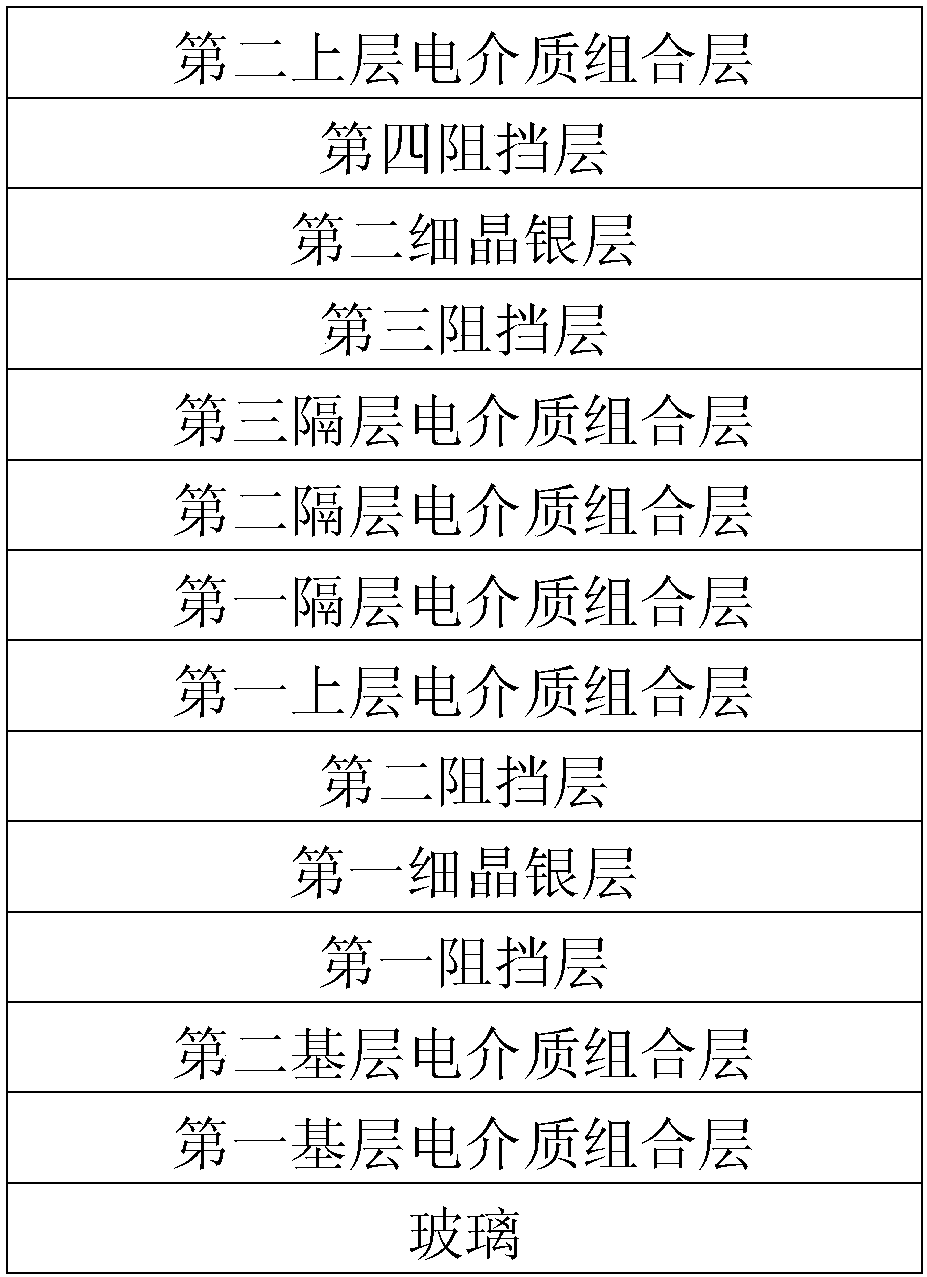

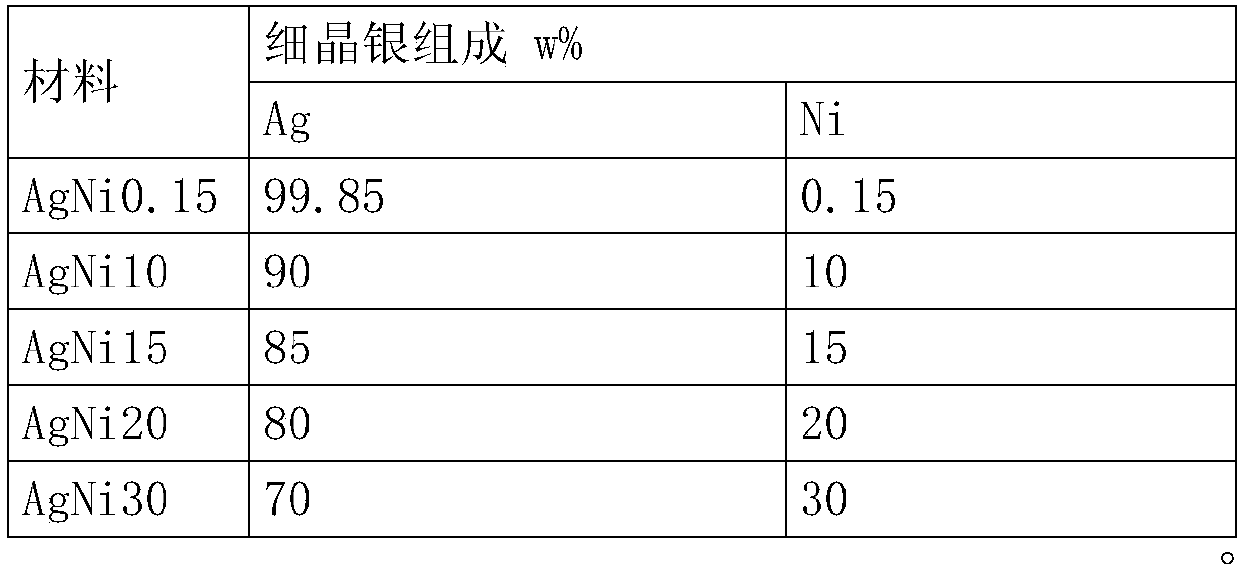

[0065] The fine-grained silver-containing coating adjusts the film layer structure of gIR glass embodiment 1 as follows: glass, NbO x , AZO, Nb, AgNi10, Nb, AZO, NbO X , AZO, AgSnO2, AgNi10, Nb, AZO, SiO x N y .

[0066] In this embodiment, the first base dielectric combination layer is NbO x layer with a thickness of 26 nm.

[0067] In this embodiment, the second base dielectric composite layer is an AZO layer with a thickness of 10 nm.

[0068] In this embodiment, the first barrier layer is a Nb layer with a thickness of 1 nm.

[0069] In this embodiment, the thickness of the first fine-grained silver layer is 11 nm.

[0070] In this embodiment, the second barrier layer is a Nb layer with a thickness of 1 nm.

[0071] In this embodiment, the first interlayer dielectric composite layer is an AZO layer with a thickness of 10 nm.

[0072] In this embodiment, the second interlayer dielectric combination layer is NbO x layer with a thickness of 55 nm.

[0073] In this e...

Embodiment 2

[0090] The fine-grained silver-containing coating adjusts the film layer structure of gIR glass embodiment 2 as follows: glass, NbO x , AZO, Nb, AgNi10, Nb, AZO, NbO X , AZO, AgSnO2, AgNi10, Nb, AZO, ZrOx.

[0091] In this embodiment, the first base dielectric combination layer is NbO x layer with a thickness of 21 nm.

[0092] In this embodiment, the second base dielectric combination layer is an AZO layer with a thickness of 15 nm.

[0093] In this embodiment, the first barrier layer is a Nb layer with a thickness of 1.5 nm.

[0094] In this embodiment, the thickness of the first fine-grained silver layer is 11 nm.

[0095] In this embodiment, the second barrier layer is a Nb layer with a thickness of 1.5 nm.

[0096] In this embodiment, the first interlayer dielectric composite layer is an AZO layer with a thickness of 15 nm.

[0097] In this embodiment, the second interlayer dielectric combination layer is NbO x layer with a thickness of 50 nm.

[0098] In this emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com