Pyrotechnic compound for detonation and preparation method and application thereof

A pyrotechnic agent and inner tube technology, which is applied in earth-moving drilling, discharging machinery, explosives, etc., can solve the problems of easy explosion, unsafety, and danger in the operation process, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

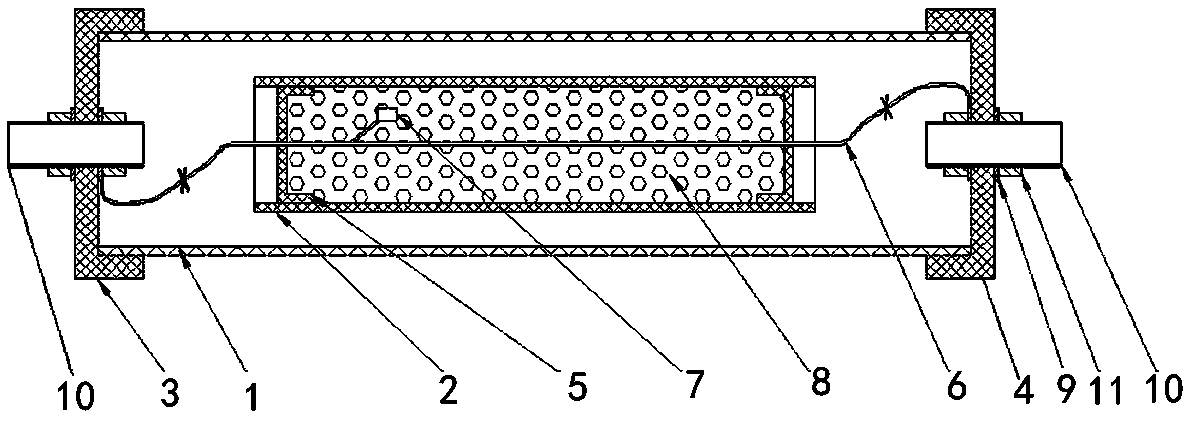

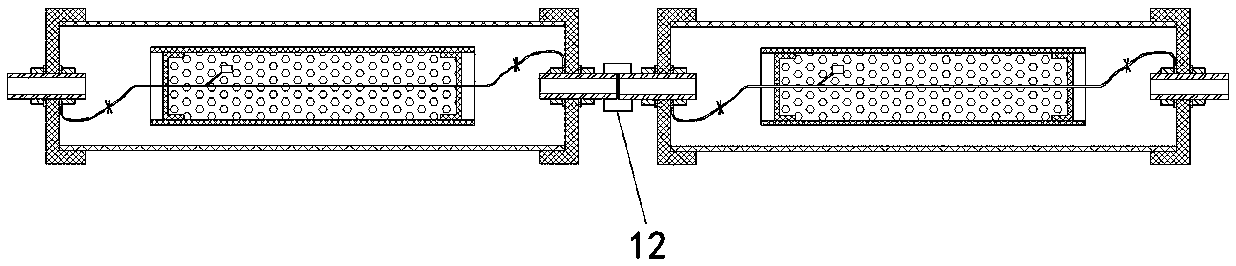

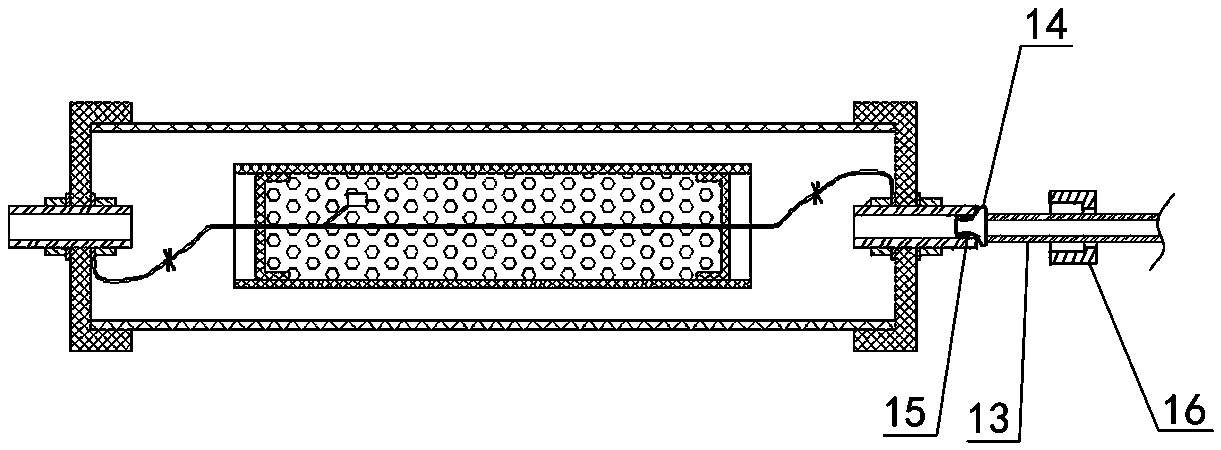

Image

Examples

Embodiment Construction

[0020] The pyrotechnic agent for blasting in the present invention is a mixture prepared in a certain proportion by oxidant (perchlorate), reducing agent (carbon, aluminum, magnesium, boron, beryllium, etc.) powder and dye catalyst; specifically, The mass ratio of each component in the pyrotechnic agent is: potassium perchlorate 30%-70%, ammonium nitrate 10%-50%, aluminum powder 2%-10%, ammonium oxalate 10%-30%; It can be ignited under certain conditions, and cannot be detonated even if it comes into direct contact with an open flame under atmospheric pressure. Preferably, the mass ratio of each component in the pyrotechnic agent is: potassium perchlorate 45%, ammonium nitrate 35%, aluminum powder 5%, ammonium oxalate 15%.

[0021] The preparation method of the pyrotechnic agent for blasting in the present invention is as follows: put each component into a kneader according to a suitable mass ratio, stir for 1-2 hours, and then mix evenly. The preparation method is simple, ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com