Dyeing and finishing method of napped garments and trousers

A garment and French technology, applied in the field of dyeing and finishing of fleece garments, can solve the problems that cellulose fibers are difficult to achieve, keep warmth, and wind resistance cannot be adapted, and achieve a high degree of automation, less human interference, and accurate bath ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In the present embodiment, the method for dyeing and finishing fleece pants, described fleece pants adopts 21 S C / 150D French rib fabric is woven and the desired color is pine green.

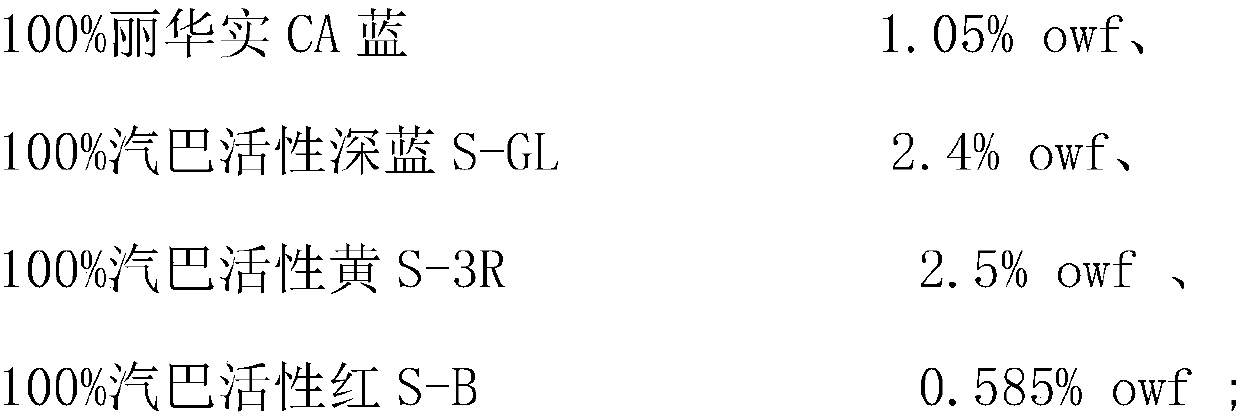

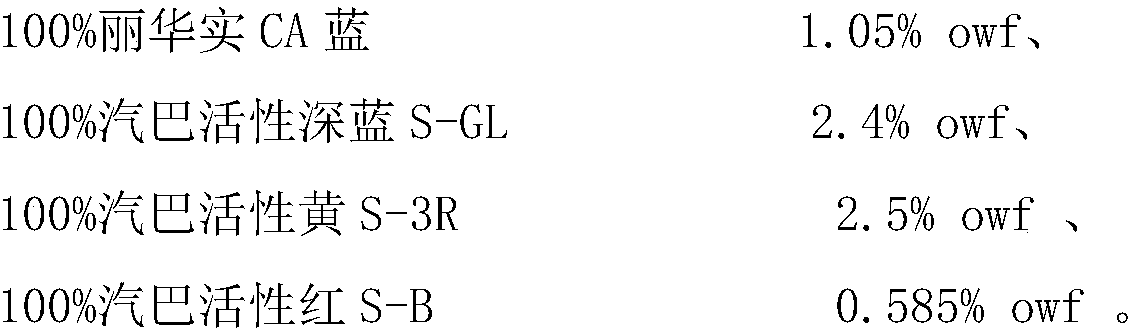

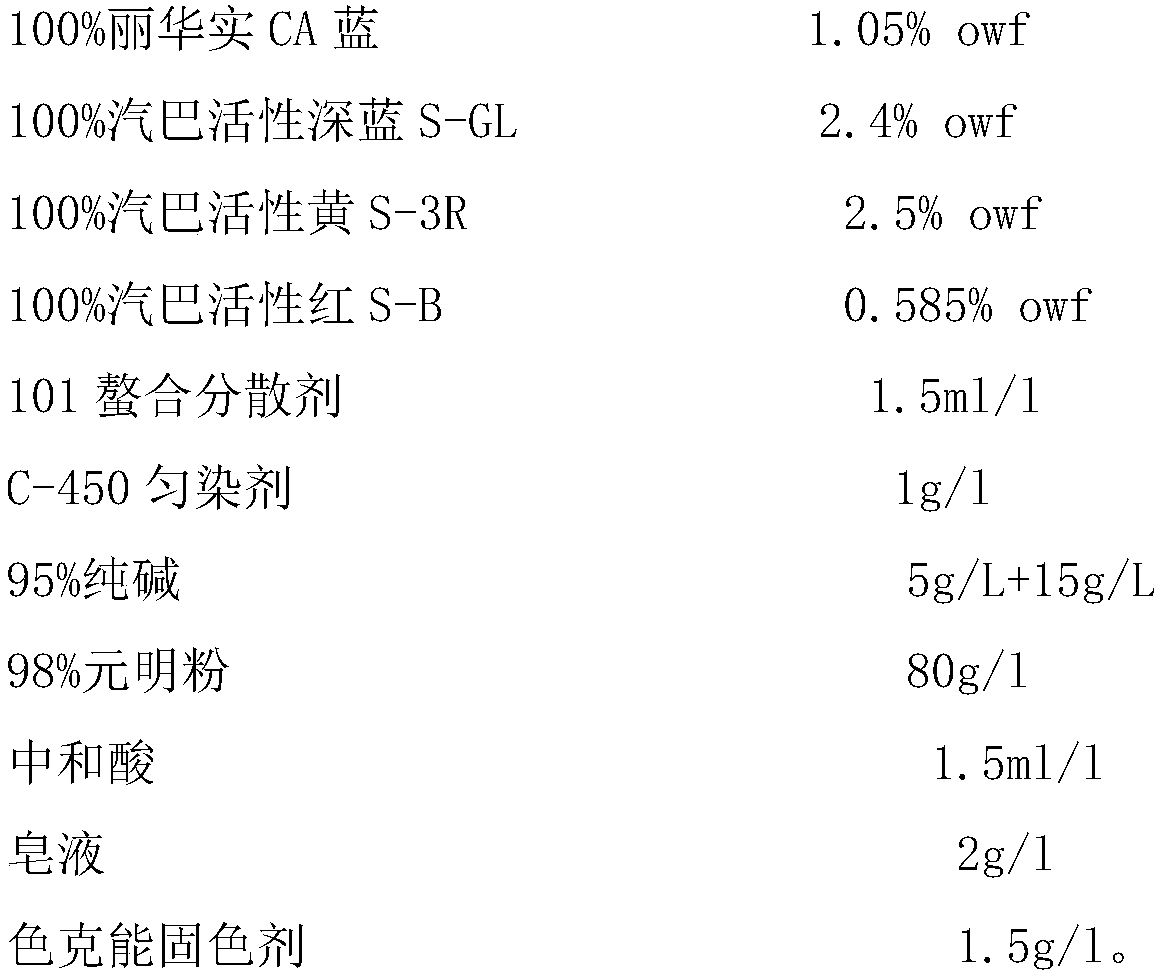

[0052] Wherein, the fabric is dyed with the following dyes, ingredients and auxiliary agents:

[0053]

[0054] The dyeing process is as follows:

[0055] Putting water into the dyeing machine according to the amount of pre-treated cotton knitted fabrics in the dyeing machine and a predetermined liquor ratio;

[0056] Raise the water temperature to 40°C;

[0057] Add 80g / L sodium bicarbonate, 1g / L leveling agent and 5g / L soda ash to the water in 5 minutes by circular injection, and keep warm at 40°C for 15 minutes;

[0058] Quantitatively with the time of 15 minutes (quantitative in the present invention refers to the function that utilizes equipment to provide, all materials are all added in the time of setting by equipment automatic linearity. The same below) After injecting all d...

Embodiment 2

[0072] This embodiment is a further processing on the basis of Embodiment 1.

[0073] In the traditional method of softening in the water bath of the dyeing tank, the hydrophilic softener is dissolved in water and does not fully adhere and penetrate into the fabric. The effect is very poor and the hand feels rough, not to mention the elastic recovery rate of the fabric, and the cost is relatively high.

[0074] The system soft of present embodiment is to make soft on the sizing machine: about 80L-100L of rolling groove of sizing machine, non-ionic hydrophilic softening agent consumption 15g / l ± 1, according to the following process conditions, the liquid carrying rate is 90%-100% , The setting speed is 20m / min, the overfeed is 20-25% for setting, and the setting temperature is set at 180℃~183℃. The preparation and shaping of the method are simultaneously reduced and the labor efficiency is improved.

[0075] The selection of non-ionic hydrophilic softener in the above process...

Embodiment 3

[0079] This embodiment is a further processing on the basis of Embodiment 2.

[0080] complex:

[0081] 20 with a width of 136cm±2 after setting through the needle board widening machine S C / 150D French rib width to 163cm±2;

[0082] Spray the colloidal particles evenly at 20 S One side of C / 150D French rib polyester;

[0083] Through hot melting, the temperature is 165℃﹢2℃ to melt the rubber particles;

[0084] By pressing, make TEDA cotton with 20 S C / 150D French rib firmly bonded;

[0085] After stacking loose rolls, the 20% cotton compounded with TEDA cotton S The width of C / 150D French rib is retracted to 140cm+2 width.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com