Assembly type prefabricated hollow column

A hollow-column, prefabricated technology, applied in columns, pillars, piers, etc., can solve the problems of long solidification and hardening time, inconsistent spirit, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

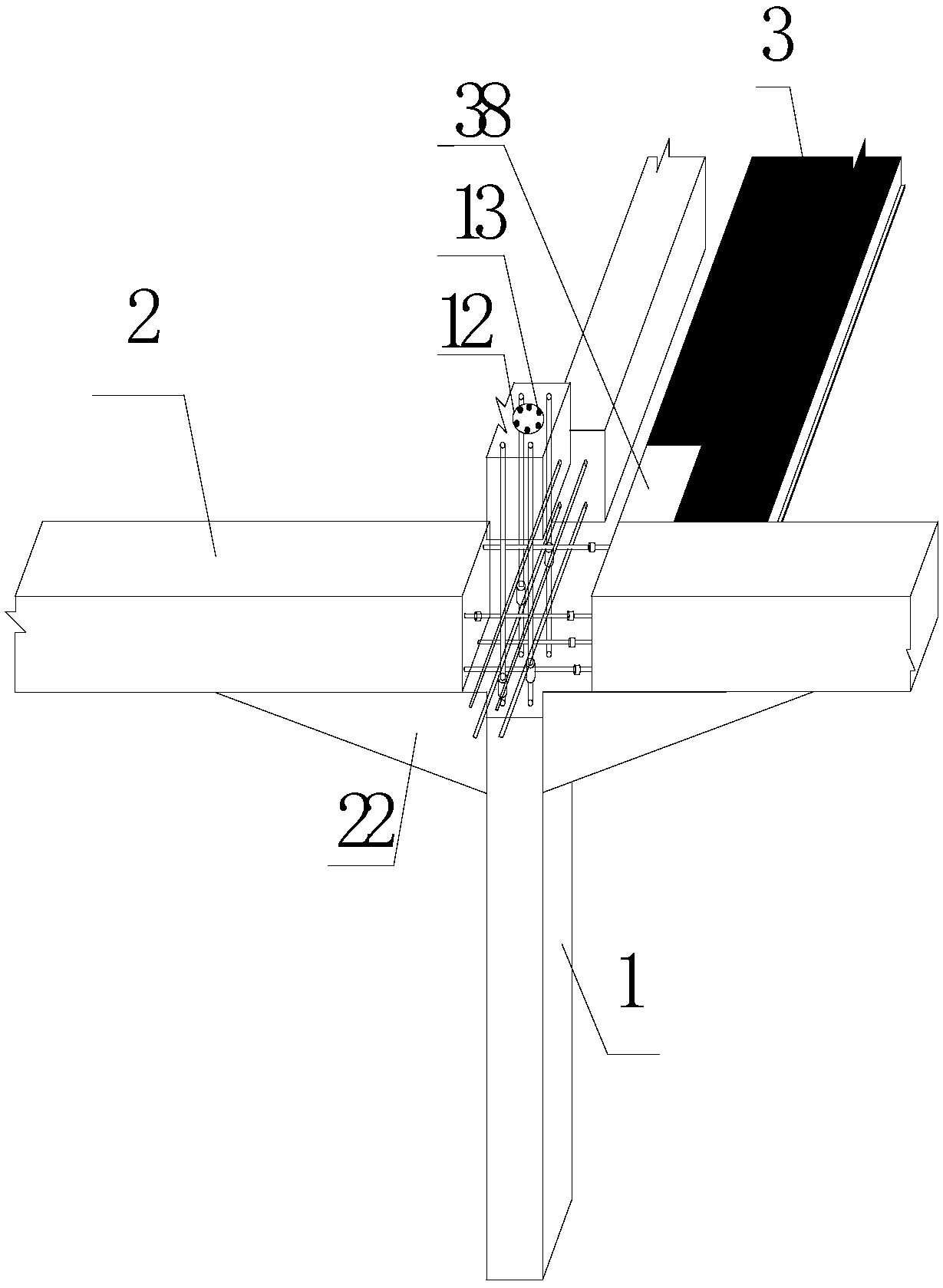

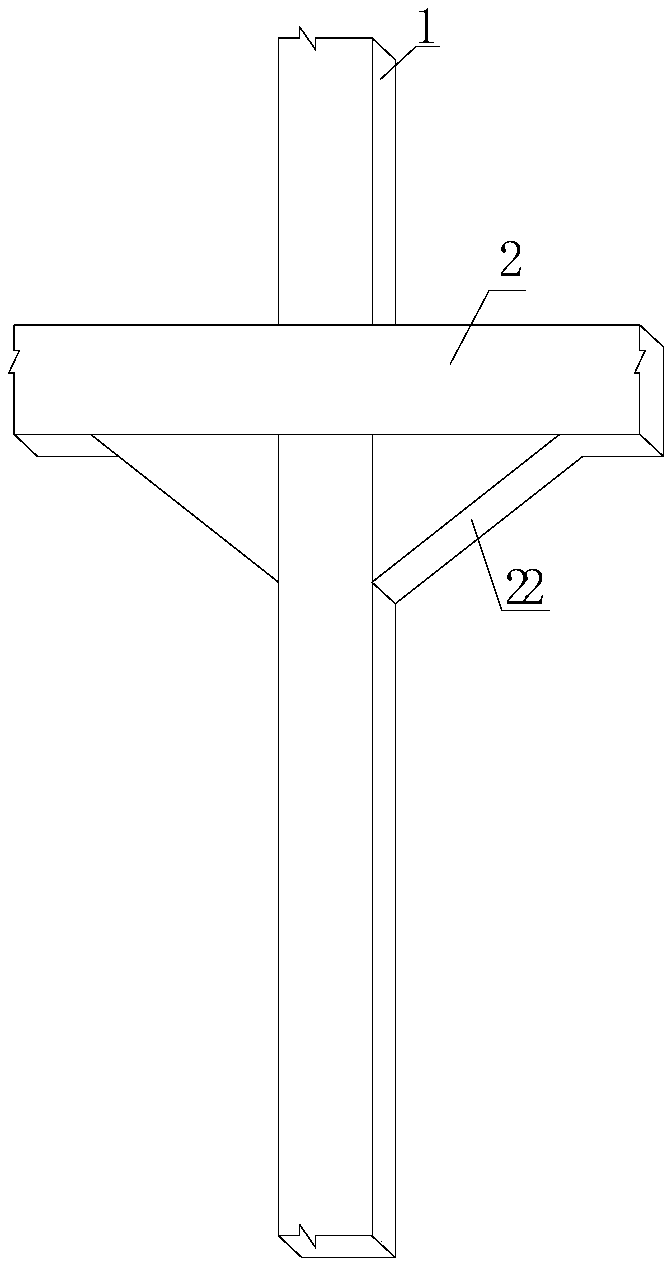

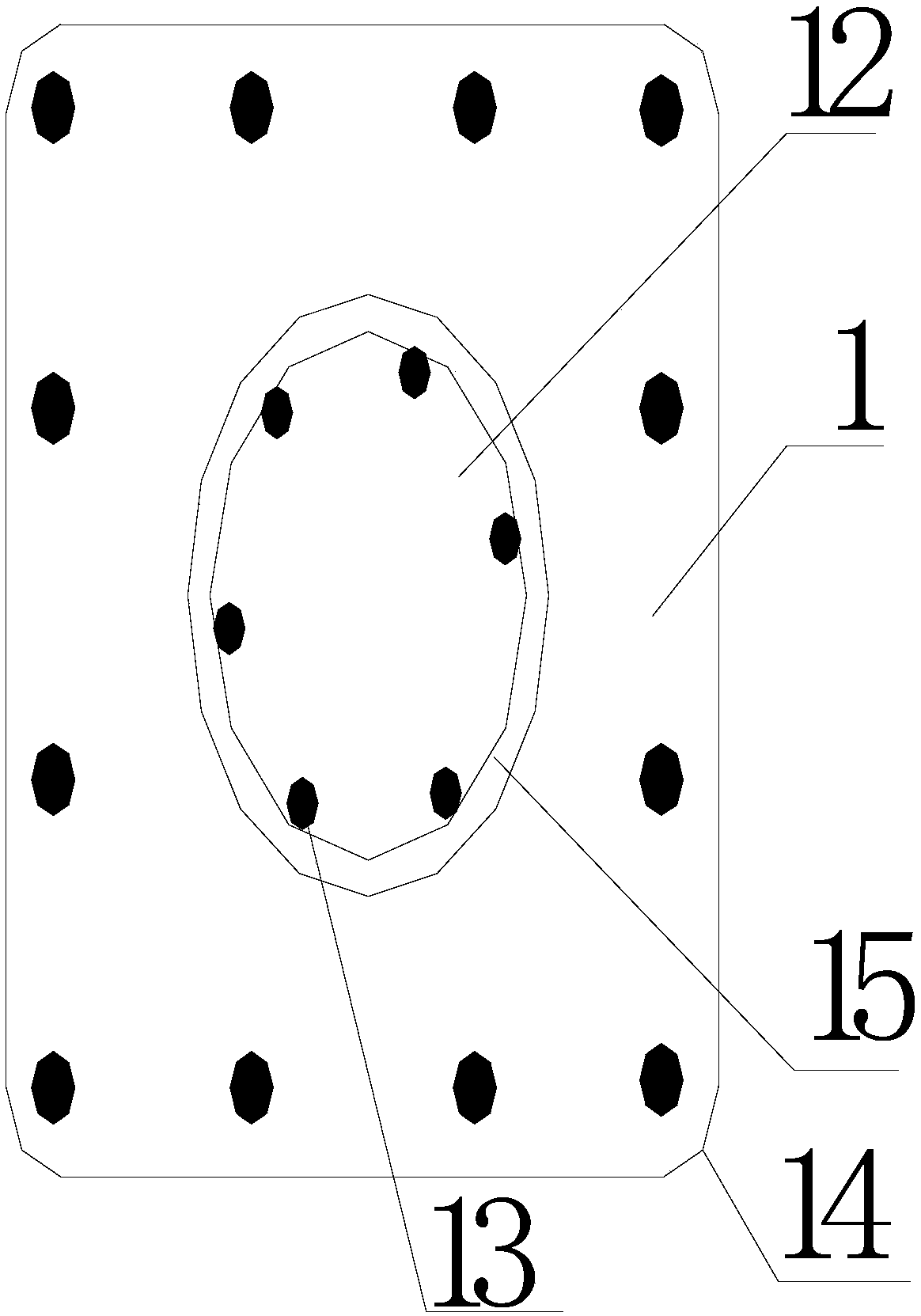

[0020] figure 1 Invented a prefabricated hollow column node diagram embodiment. When the present invention is implemented, the steel cage 13 is first connected vertically, and the connected steel cage 13 is about 1000mm higher than the prefabricated hollow column 1 to ensure the connection head of the steel cage 13 In the middle of the hollow column 1; hoist the hollow column 1, its hollow hole 12 is aligned with the steel cage 13, so that the steel cage 13 is inserted into the hollow hole 12 of the prefabricated hollow column 1; connect the upper and lower sections of the prefabricated hollow column 1 to receive vertical force Reinforcing steel, vertical force-bearing rebar The medium-length rebar is connected with the vertical force-bearing short rebar of another section of the prefabricated hollow column. At the connection point of the two sections of hollow columns, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com