A gas mixture combustion system

A combustion system and mixed gas technology, which is applied to gas fuel burners, burners, combustion types, etc., can solve the problems of insufficient ignition energy, unreliable ignition, and easy quenching of the fire nucleus, so as to facilitate the observation of the flame and maintain the flame. Stable and good ignition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

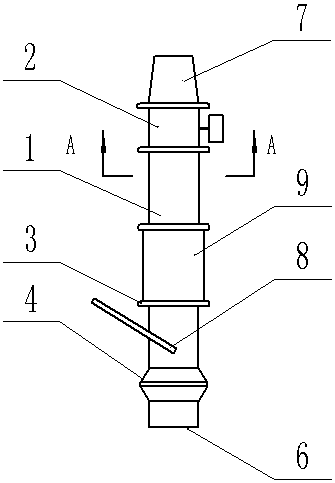

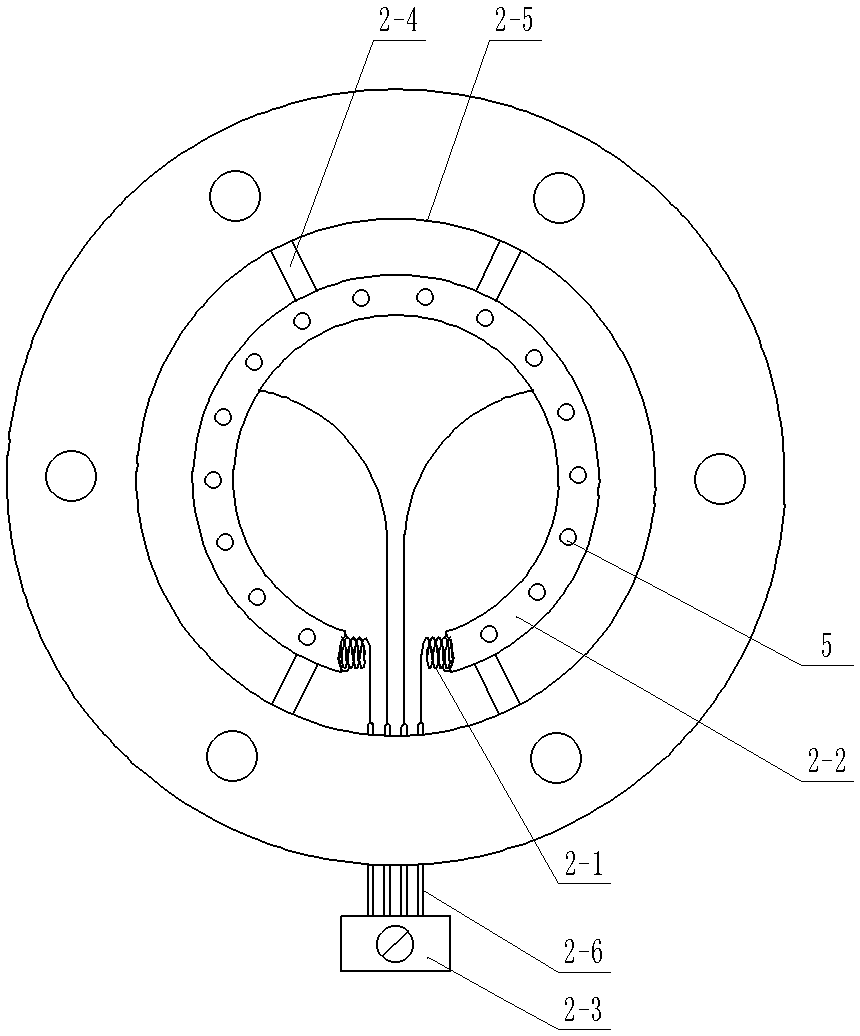

[0037] The specific embodiment of the present invention will be further described below by taking the mixed gas of methanol and air as an example.

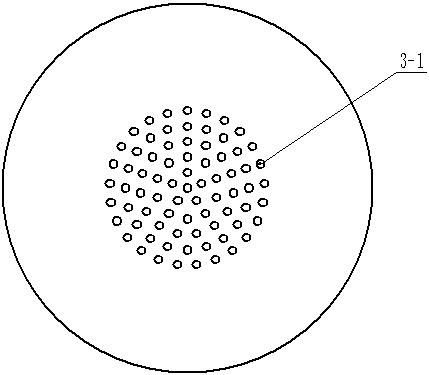

[0038] When in use, determine the wiring electrode of the igniter according to the flow rate of the mixed gas, turn on the ignition switch 2-3, the methanol-air mixture passes through the flame arrester 4 and the flame stabilizer 3 to the igniter 2, and the electric heating wire in the porous high-temperature resistant tube 2-2 2-1 is used as a heat source to ignite the mixed gas; when the methanol-air mixed gas flows through the uniformly distributed spoiler holes 3-1 on the flame stabilizer 3, the mixed gas forms a recirculation zone behind the spoiler holes 3-1, and the reflux of high-temperature gas is automatically provided The energy required to ignite the fresh combustible mixture, so that the fresh combustible mixture is continuously ignited, and the ignition switch 2-3 of the igniter is turned off after the combustion is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com