Oil-fired boiler ignition system

An ignition system, a technology for oil-fired boilers, applied in burners, combustion methods, liquid fuel supply/distribution, etc., can solve problems such as unfavorable ignition, excessive or insufficient fuel oil, etc., to facilitate troubleshooting, improve flow performance, and good versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described below in conjunction with specific embodiments.

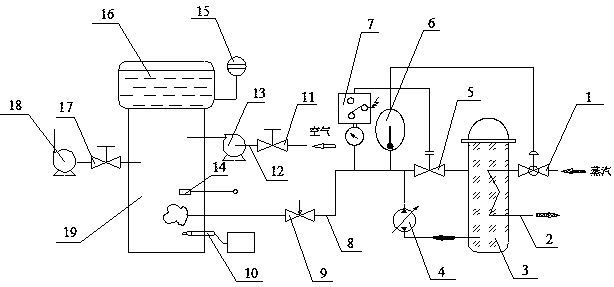

[0016] Please refer to figure 1 , the fuel oil boiler ignition system of the present invention comprises oil storage tank 3, fuel oil pipeline 8, and fuel oil pipeline 8 communicates with oil storage tank 3, also comprises microprocessor, pressure sensor 7, pressure regulating valve 5; Pressure sensor 7 and pressure The regulating valve 5 is set on the fuel pipeline 8; the hydraulic pump 4 pumps the fuel out of the oil storage tank 3 and flows into the fuel pipeline 8; the pressure sensor 7 is used to sense the fuel pressure in the fuel pipeline 8, and the pressure regulating valve 5 can be adjusted Its own opening is used to adjust the fuel delivery flow in the fuel pipeline; the microprocessor is used to receive the pressure value sensed by the pressure sensor 7, compare the pressure value with the preset pressure value, and adjust the pressure according to the comparison result....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com