Method and device for measuring gyroscope frequency characteristics

A technology of frequency characteristics and measurement methods, applied in the field of measurement, can solve problems such as the limited frequency range of angular vibration tables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

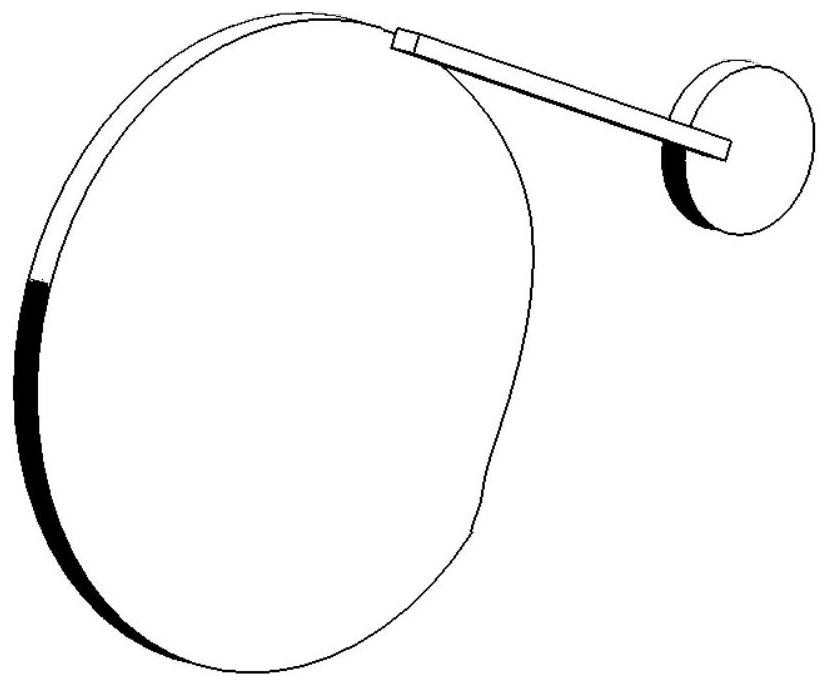

[0030] Gyro frequency characteristic device:

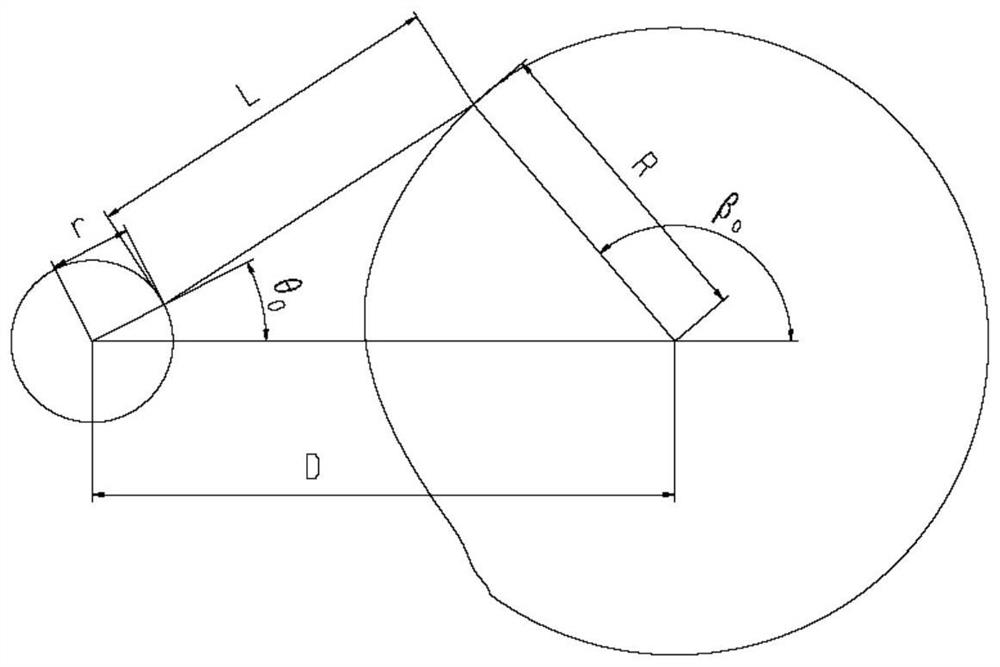

[0031] The geometric parameters of the gyro frequency characteristic measuring device are as follows:

[0032] Driving wheel driven wheel center distance D=180mm

[0033] Driving wheel radius r=25mm

[0034] The length of the connecting rod L=113.7mm

[0035] Driving wheel initial position angle θ 0 =27.1°

[0036] The initial position angle of driven wheel rotation β 0 =130.4°

[0037] The distance between the working point of the cam surface of the driven wheel and the rotation center of the driven wheel at the initial position R0=96mm

[0038] The contour equation of the working part of the driven wheel is:

[0039] 113.7 2 =[25×Cosθ-R·Cos(0.2×Sin(θ-27.1)+130.4)] 2

[0040] +[25×Sinθ-R·Sin(0.2×Sin(θ-27.1)+130.4)] 2

[0041] Among them, θ is the rotation angle of the driving wheel and R is the distance between the working point of the cam surface of the driven wheel and the center of rotation of the driven wheel.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com