Power transmission line stockbridge damper falling-off defect detection method

A transmission line and defect detection technology, applied in image data processing, instruments, calculations, etc., can solve the problems of strong vibration, high work intensity, wire fatigue damage, etc., to achieve high accuracy and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The anti-vibration hammer fall-off defect detection method of the transmission line of the present invention comprises the following steps:

[0028] A. Anti-vibration hammer labeling: Obtain the anti-vibration hammer historical template image collection of the transmission line, and mark the corresponding position information of the anti-vibration hammer on each historical template image of anti-vibration hammer;

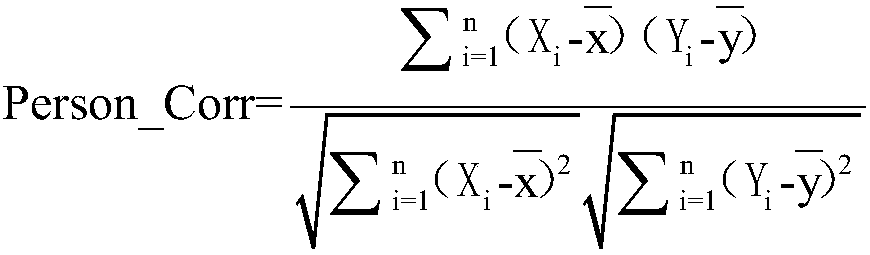

[0029] B. Template screening: Obtain the anti-vibration hammer image of the transmission line to be detected, and then calculate the similarity between each image in the anti-vibration hammer history template image set and the anti-vibration hammer image to be detected, and then select the anti-vibration hammer history with the highest similarity The template image is used as the detection template image;

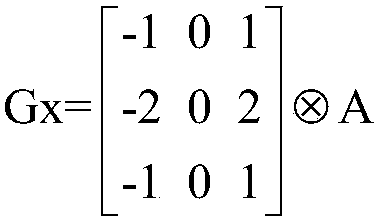

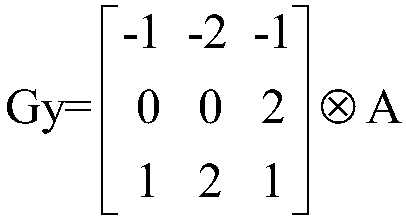

[0030] C. Offset estimation and compensation of the image to be detected: the horizontal and vertical image pixel offsets x, y corresponding to the detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com