Dust cleaning device for filtering net of power equipment

A technology for power equipment and cleaning devices, which is applied to the cooling/ventilation of circuit devices, substation/power distribution device shells, substations/switching devices, etc., which can solve the problems of heavy dust particles and reduce the cleaning quality and occupancy Space, reduce the effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

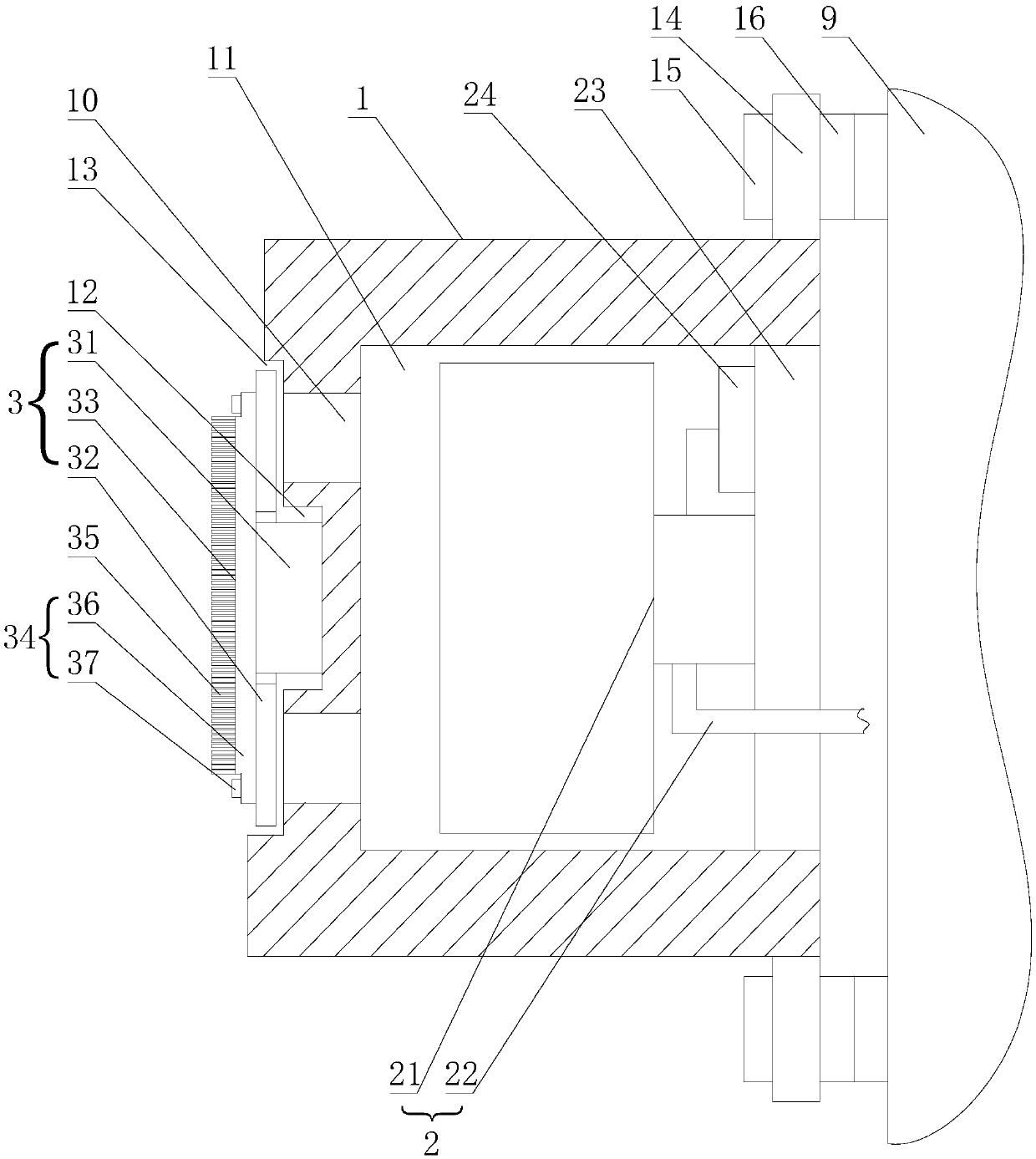

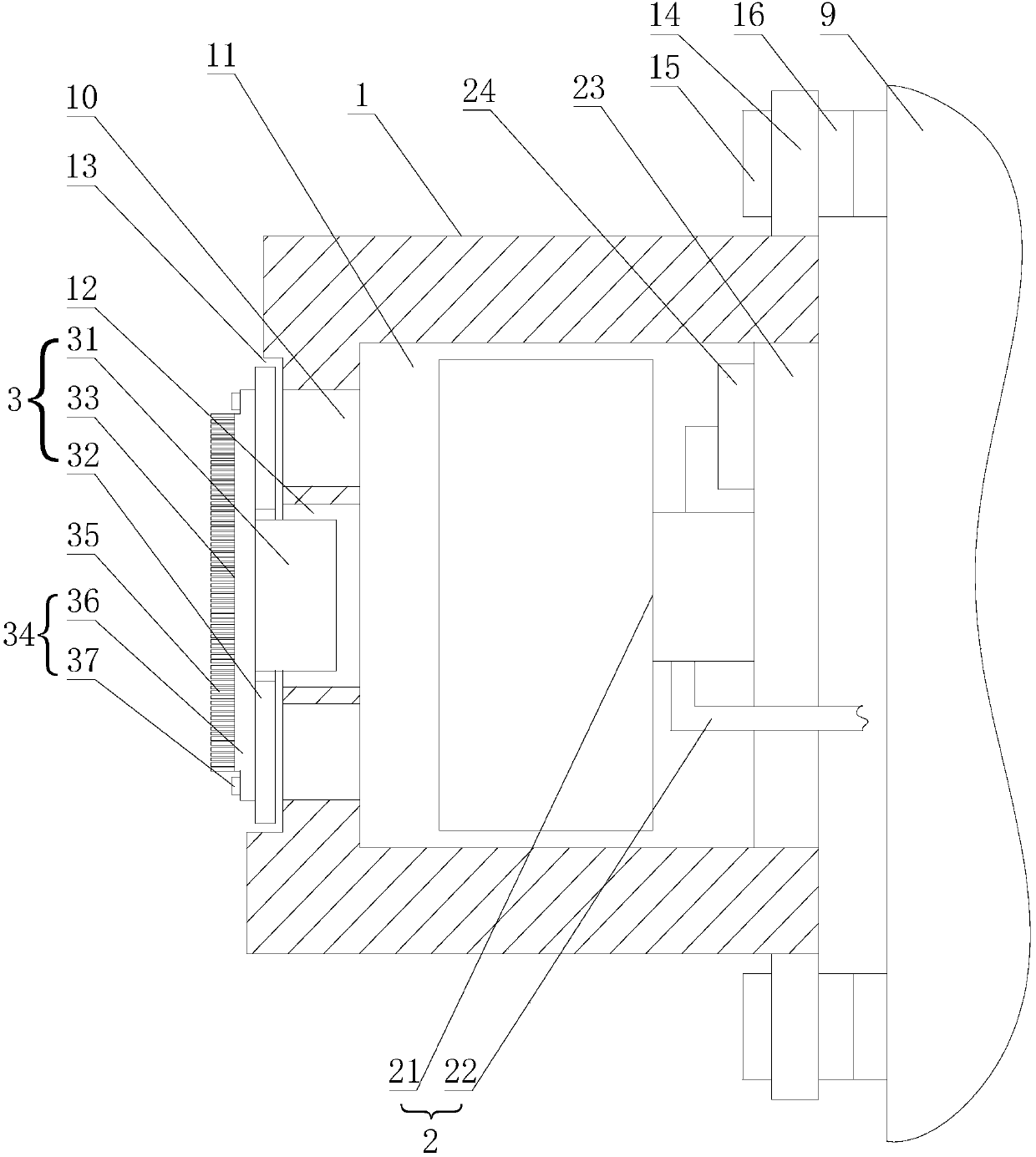

[0022] Such as figure 1 As shown, the filter dust removal device of power equipment includes a base 1, a driving mechanism 2 and a cleaning brush 3. The base 1 is provided with a first mounting portion 11 and a second mounting portion 12, and the driving mechanism 2 The cleaning brush 3 is installed on the base 1 through the first installation part 11, and the cleaning brush 3 is installed on the base 1 through the second installation part 12, so that the entire filter dust removal device is formed as a whole, reducing the entire filter dust removal device The installation takes up space, and the overall structure is compact, and the assembly is simple. The cleaning brush 3 relies on the driving force of the driving mechanism 2 to automatically clean the dust on the filter, which can ensure that the filter is not blocked and can reduce the existing manual cleaning work Intensity and cleaning quality, it can effectively solve the problem of anti-clogging of the filter, ensure the...

Embodiment 2

[0027] Like the filter dust removal device of power equipment described in the first embodiment, this embodiment has the following differences: figure 2 As shown, the connecting hole communicates with the cavity, and the rotating shaft is arranged in the cavity. When in use, the wind generated by the fan 21 flows to the cleaning brush 3 through the connecting hole and the ventilation hole 10 to realize the synchronous rotation of the rotating shaft 31 and the blade 32, and further The cleaning effect of the brush 33 is improved.

[0028] The power equipment in this embodiment refers to the GIS control cabinet of an unattended substation. When the GIS control cabinet is in use, dust particles will block the filter. If it is not cleaned in time, it will inevitably affect heat dissipation and lead to signal collection and communication. The malfunction of control and protection functions may endanger the safety of the power grid and cause accidents. The dust remover in this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com