Coated gyro and manufacturing method thereof

A manufacturing method and technology for gyroscopes, which are used in gyroscopes, entertainment, toys, etc., can solve the problems of expensive stainless steel raw materials, high manufacturing costs of gyroscopes, and high selling prices, and achieve the effects of low cost, extended life, and improved life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

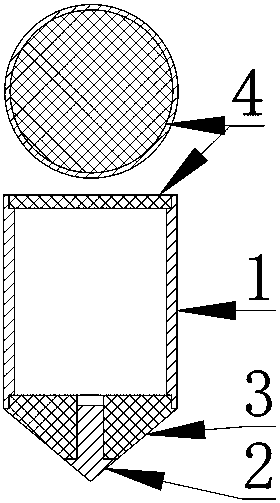

[0015] All Metal Coated Gyro, in Example figure 1 Components 1, 2, and 3 are actually a whole without a top cover 4. Melt the collected low-cost metal scrap in a special furnace and pour it into a precision casting mold for precision casting, then finish it properly according to the situation, and finally coat the surface with one or more layers of composites with a thickness of about 1μm-3μm by vapor deposition It is a coating with wear-resistant, corrosion-resistant and decorative functions.

[0016] Non-all metal coated gyroscopes, in the example figure 1 The main metal parts 1 and the metal rotating culet 2 are still made of metal. The manufacturing method is: melting the collected cheap metal scraps in a special melting furnace and pouring them into precision casting molds for precision casting, and then finishing them as appro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com