Organic waste gas treatment device

A treatment device and organic waste gas technology, applied in the direction of gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of production and living ecological environment adverse effects, waste gas can not meet the standard discharge, increase the pressure of enterprises, etc., to achieve land occupation The effect of small area, simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

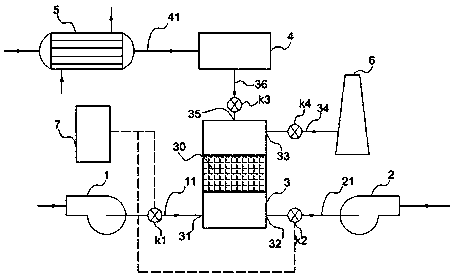

[0021] This embodiment provides a device for treating organic waste gas with a simple structure. The device has a high degree of automation, can not only reuse activated carbon, does not require hazardous waste treatment for activated carbon, but also has a good waste gas treatment effect. For details, please refer to figure 1 The schematic diagram of the structure is shown.

[0022] The device comprises a first fan 1, a second fan 2, an activated carbon adsorption unit 3, a catalytic oxidation burner 4, a heat exchanger 5, a chimney 6 and a controller 7, wherein the activated carbon adsorption unit 3 is provided with an activated carbon layer 30 .

[0023] The first fan 1 is connected to the first inlet 31 of the activated carbon adsorption unit 3 through the first air inlet pipe 11, and the second fan 2 is connected to the second inlet 31 of the activated carbon adsorption unit 3 through the second air inlet pipe 21. Import 32 connections.

[0024] The first outlet 33 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com