Special high speed piston type electric vacuum pump body structure

An electric vacuum pump, piston-type technology, applied in the direction of piston pumps, variable-capacity pump components, pumps, etc., can solve the problems of weak connecting rod structure and easy failure, etc., and achieve simple structure, high vacuum efficiency, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

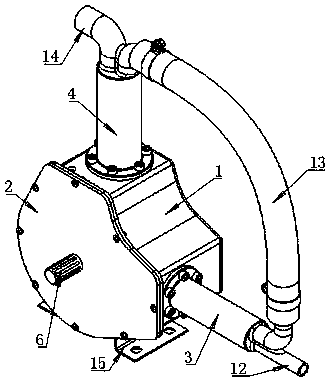

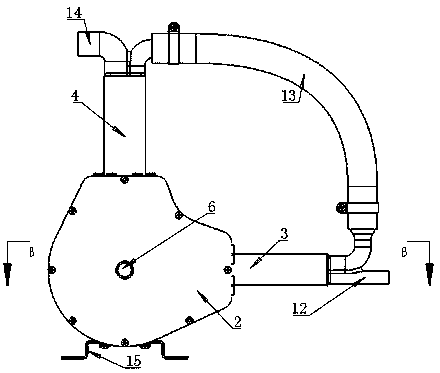

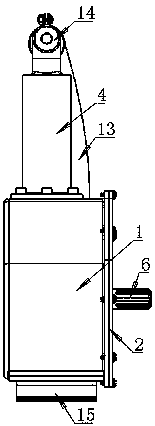

[0021] Such as Figure 1 to Figure 9 As shown, a special high-speed piston-type electric vacuum pump pump body structure, which adopts a new structural design, achieves the effect of rapid vacuuming through a simple structure, and the effect is better during use, and it is more convenient during use , it is more flexible in installation, and the production cost is lower, which can reduce the overall use cost of the high-speed piston electric vacuum pump. It includes a pump housing structure 1, which is the primary shell of the pump housing structure. The right side of the pump housing structure 1 is the first assembly end, the upper end of the pump housing structure 1 is the second assembly end, and the front of the pump housing structure 1 is connected with a cover plate structure 2, which will pump The shell structure is sealed to ensure better vacuuming effect during use, so this position must ensure the tightness of the connection when connecting. The first assembly end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com