Nonwoven funnel with guide elements for compressing fiber nonwovens

A technology of non-woven fabrics and guiding elements, applied in fiber processing, textile and papermaking, drafting equipment, etc., which can solve the problems of fiber belt quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

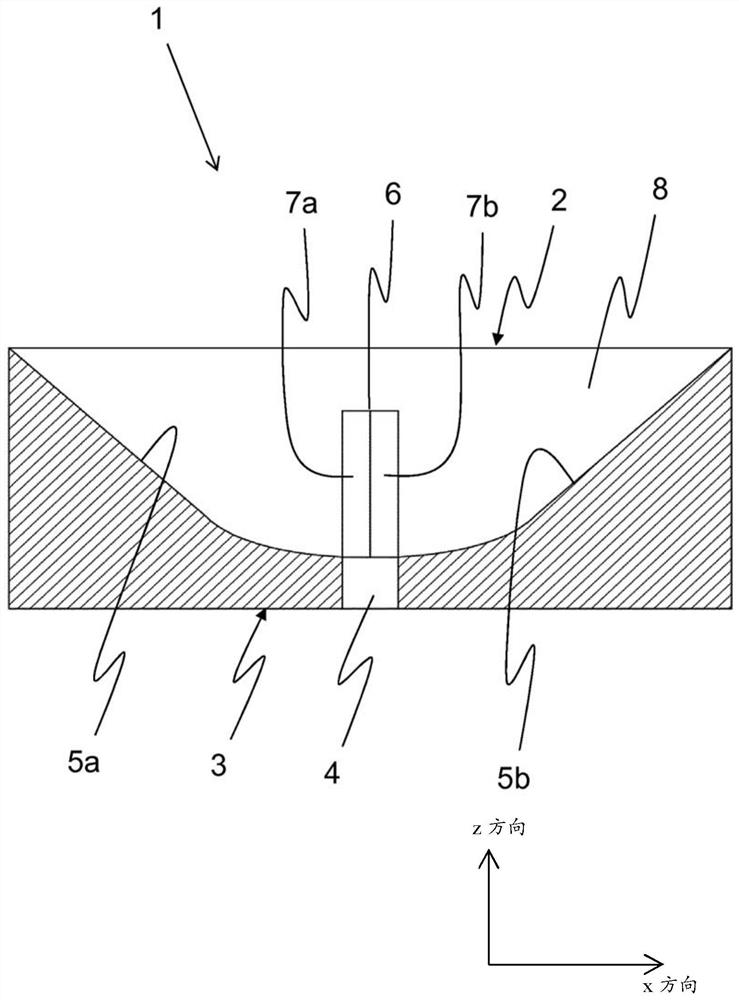

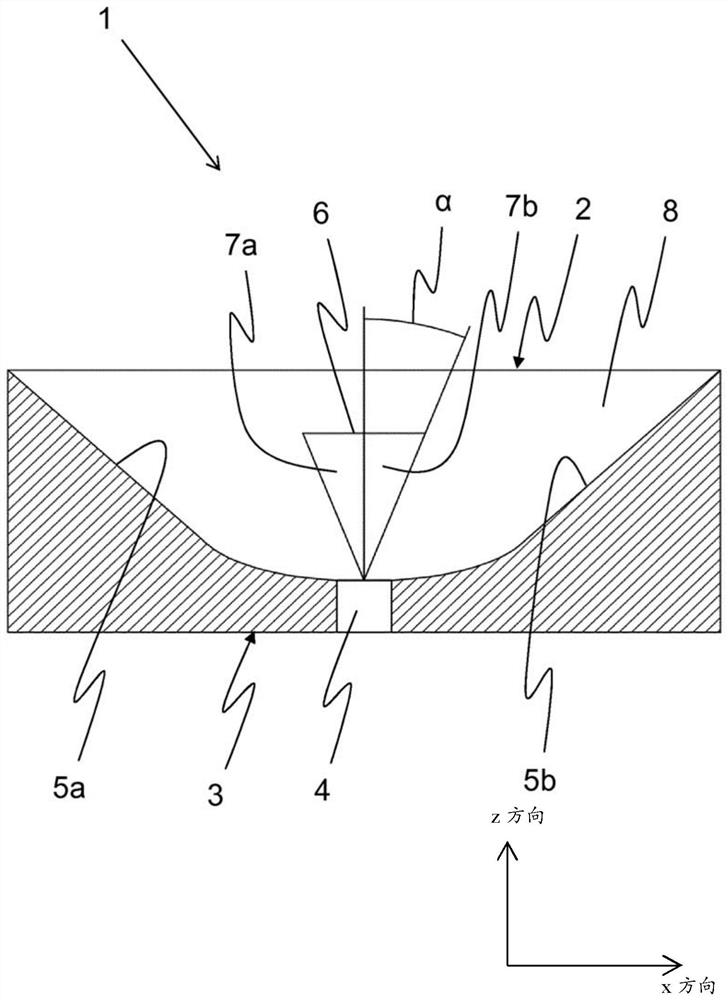

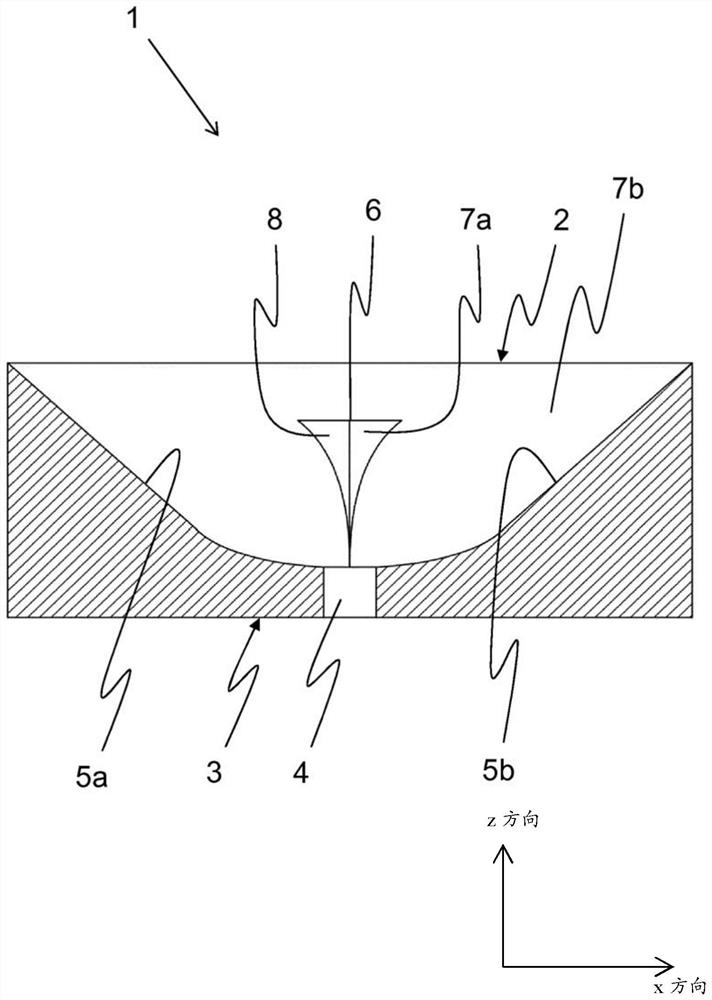

[0047] figure 1 A sectional view of a fleece funnel 1 with an inlet side 2 formed elongately in the x-direction is shown. The fibrous fleece, not shown here, enters the fleece hopper 1 via the inlet side 2 . Spaced apart from the input side 2 in the z-direction is an output side 3 . An outlet opening 4 is formed in the outlet side 3 , through which the fibrous fleece compressed into a fiber strip emerges from the fleece hopper 1 . The outlet opening 4 is preferably configured with a circular cross section. In the present exemplary embodiment, two guide surfaces 5 a , 5 b are arranged between the inlet side 2 and the outlet side 3 , which form the actual funnel function of the nonwoven funnel 1 . The fibrous fleece stretched in the x-direction enters the fleece hopper 1 via the input side 2 . At least the edge region of the fibrous nonwoven hits the guide surfaces 5 a , 5 b and is diverted from there in the direction of the output opening 4 , where it leaves the nonwoven fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com