Waste tire recovery processing device

A technology for recycling waste tires, applied in plastic recycling, recycling technology, mechanical material recycling, etc., can solve the problems of insufficient contact between tires and heat sources, low recycling rate, etc., to improve cracking efficiency, facilitate discharge, The effect of high cracking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

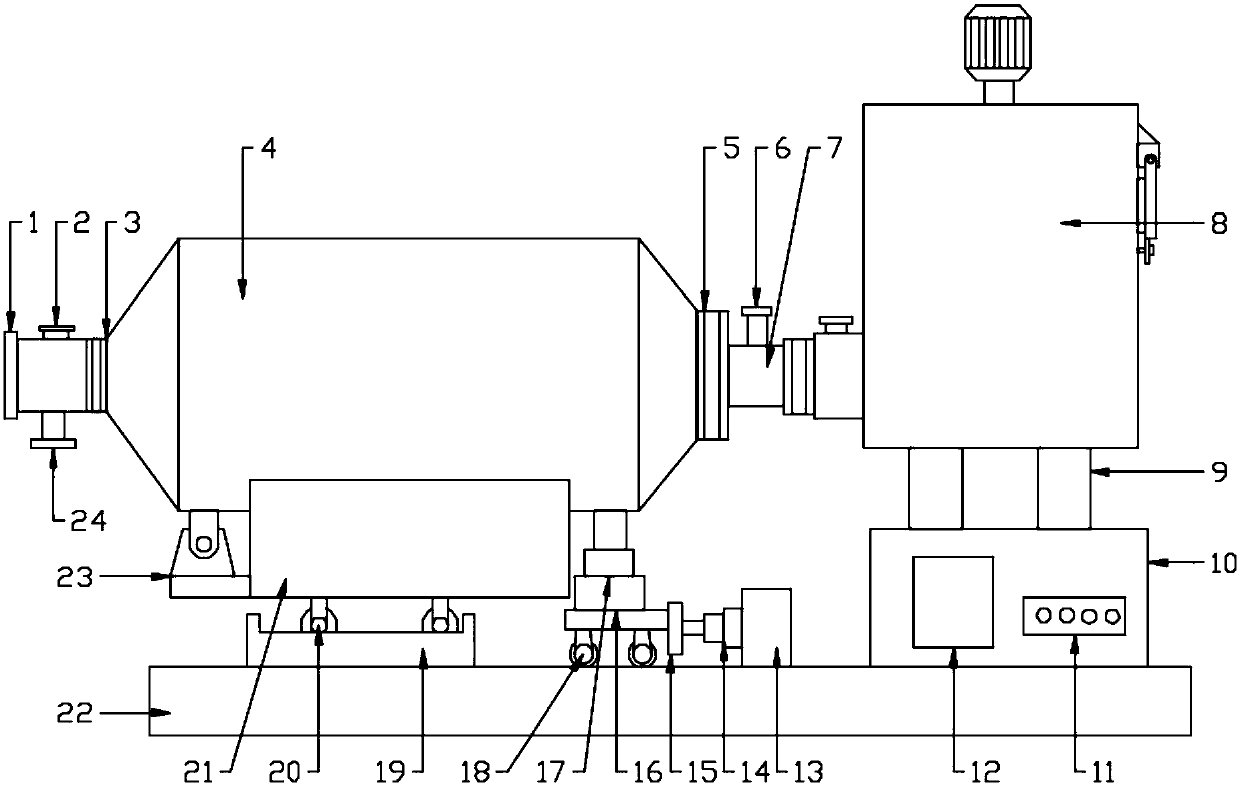

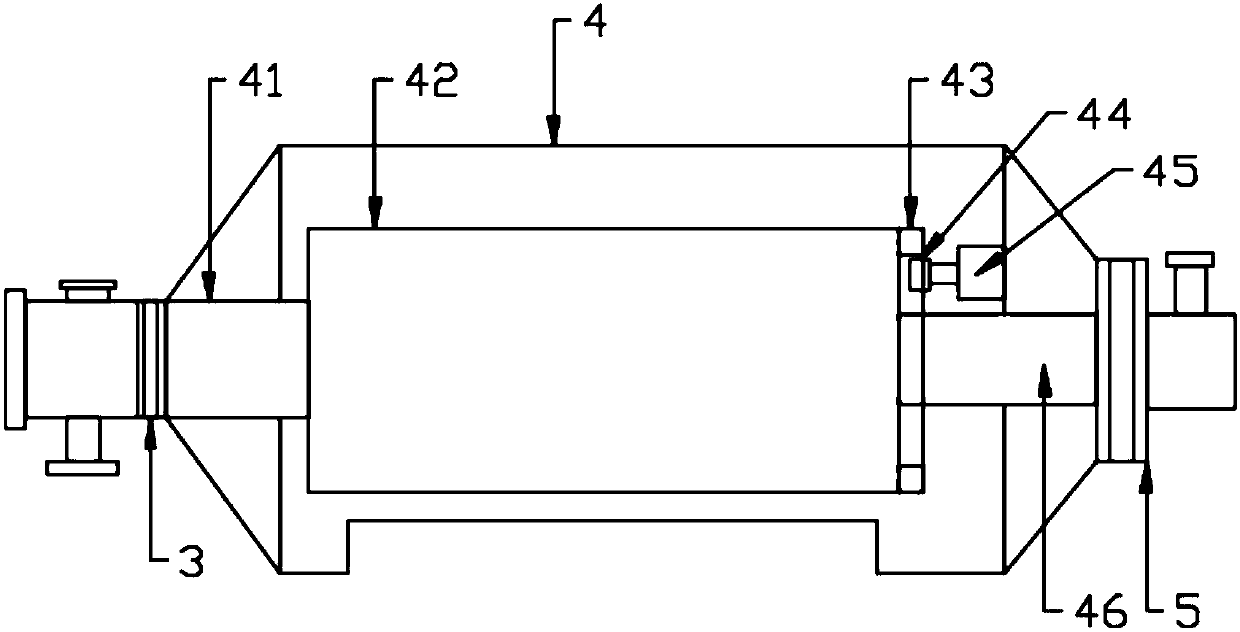

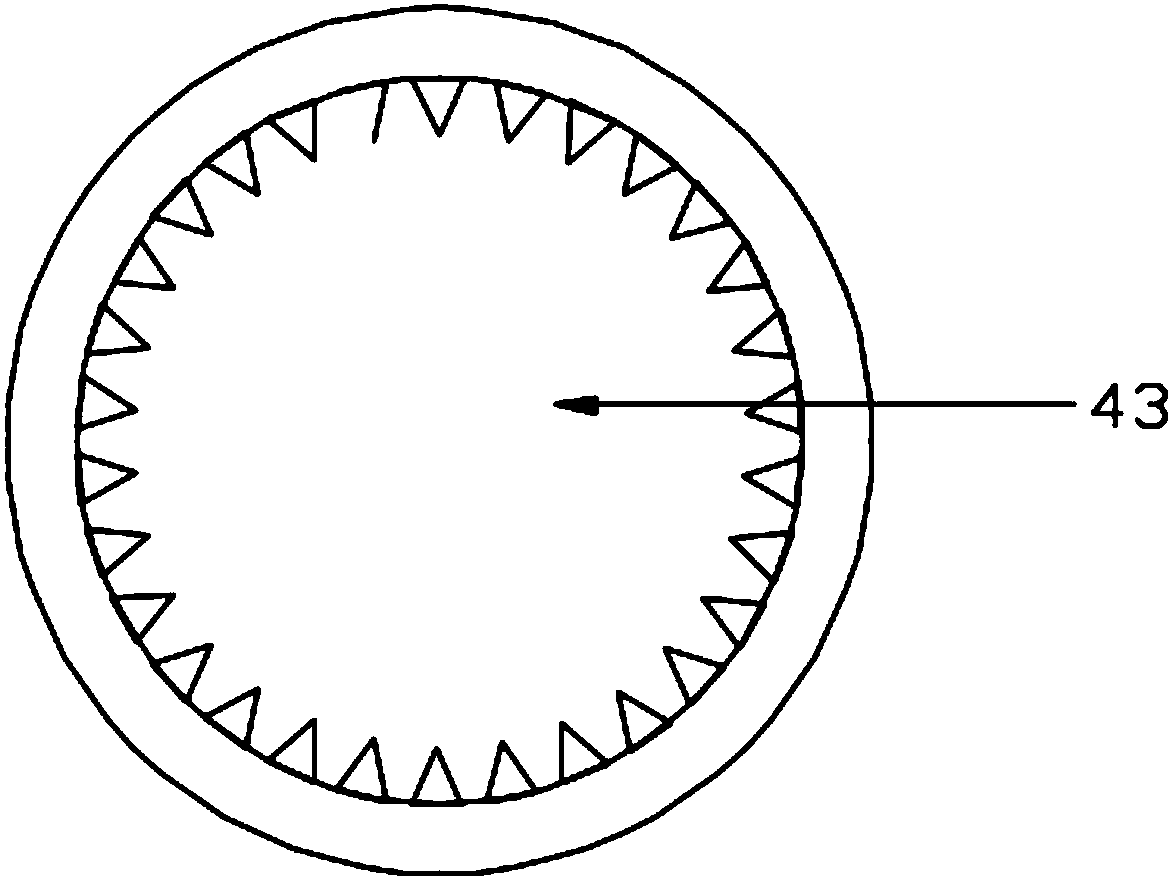

[0022] see Figure 1-4 , a recycling and processing device for waste tires, comprising a cracking box 4, a crushing box 8, a fixed platform 10 and a fixed bottom plate 22, the fixed bottom plate 22 is provided with a support plate 13, and a first cylinder 14 is fixed on the support plate 13. The left side of a cylinder 14 is fixed with a push plate 15 by a push rod, and the push plate 15 is fixed on the fixed plate 16. The lower end of the fixed plate 16 is provided with a first pulley 18, and the first pulley 18 is provided with a braking device. There is a second cylinder 17, the left side of the second cylinder 17 is provided with a heating device 21, the left side of the heating device 21 is provided with a supporting platform 23, the lower end of the heating device 23 is provided with a second pulley 20, and the lower end of the sec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap