Preparation method of oxidation modified cb/cfdsf/ag-80 epoxy resin composite

A technology of AG-80 and epoxy resin, which is applied in the fields of dry-cleaning fiber products, fiber treatment, textiles and papermaking, etc., can solve problems such as insufficient mechanical properties such as strength, affecting the performance of composite material matrix, and affecting the physical properties of composite material systems. To achieve the effect of ensuring stability and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] For the modification treatment of carbon black (CB), the inventor of the present application has studied the use of silane coupling agent to carry out modification treatment and the use of oxidant to carry out modification treatment. The protection of the present invention adopts oxidation modification CB / CFDSF / AG-80 The preparation method of oxygen resin composite material;

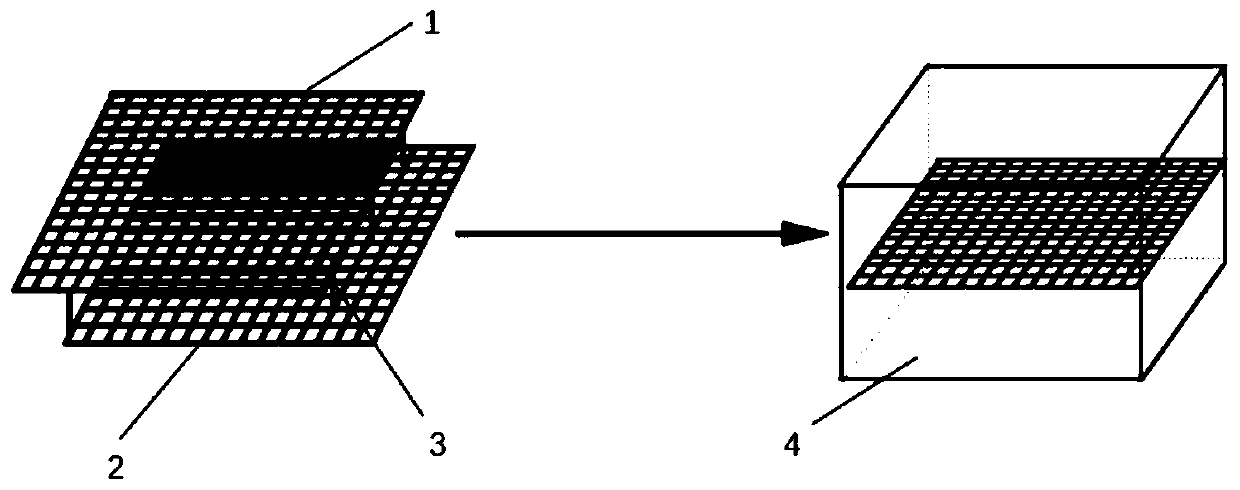

[0042] A preparation method for preparing oxidation-modified CB / CFDSF / AG-80 epoxy resin composite material, mainly comprising the following steps:

[0043] 1. Modification of carbon black (CB) with concentrated nitric acid

[0044] Use concentrated nitric acid to modify carbon black (CB). First, take 4g of carbon black and 50ml of concentrated nitric acid with a concentration of 65wt% and pour them into a beaker, heat to 100°C and stir for 2 hours, then dilute with distilled water and filter with suction , scrape off the filtered CB carefully, put it into a beaker and pour a large amount of disti...

Embodiment 2

[0051] Modification of carbon black (CB) The inventor of the present application has studied the use of silane coupling agent for modification and the use of oxidant for modification. The protection of the present invention uses oxidation modified CB / CFDSF / AG-80 epoxy The preparation method of resin composite material;

[0052] A preparation method for preparing oxidation-modified CB / CFDSF / AG-80 epoxy resin composite material, mainly comprising the following steps:

[0053] 1. Modification of carbon black (CB) with concentrated nitric acid

[0054] Carbon black (CB) is modified with concentrated nitric acid. Take 8g of carbon black and 75ml of concentrated nitric acid with a concentration of 68wt% and pour them into a beaker, heat to 100°C and stir for 2.5 hours, then dilute with distilled water and filter with suction , scrape off the filtered CB carefully, put it into a beaker and pour a large amount of distilled water to continue to dilute, after standing for a proper time...

Embodiment 3

[0061] Modification of carbon black (CB) The inventor of the present application has studied the use of silane coupling agent for modification and the use of oxidant for modification. The protection of the present invention uses oxidation modified CB / CFDSF / AG-80 epoxy The preparation method of resin composite material;

[0062] A preparation method for preparing oxidation-modified CB / CFDSF / AG-80 epoxy resin composite material, mainly comprising the following steps:

[0063] 1. Modification of carbon black (CB) with concentrated nitric acid

[0064] Carbon black (CB) is modified with concentrated nitric acid, 12g of carbon black and 100ml of concentrated nitric acid with a concentration of 70wt% are poured into a beaker, heated to 110°C and fully stirred for 3 hours, then diluted with distilled water and suction filtered. Carefully scrape off the filtered CB, put it into a beaker and pour a large amount of distilled water to continue diluting. After standing for an appropriate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap