An exposed column foot node component for installing steel columns

A column foot node and exposed technology, applied in towers, building types, buildings, etc., can solve the problems of low precision, difficult transportation and installation, and easy damage of welding, so as to improve installation accuracy, facilitate processing and transportation, and not easily deform and the effect of being destroyed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

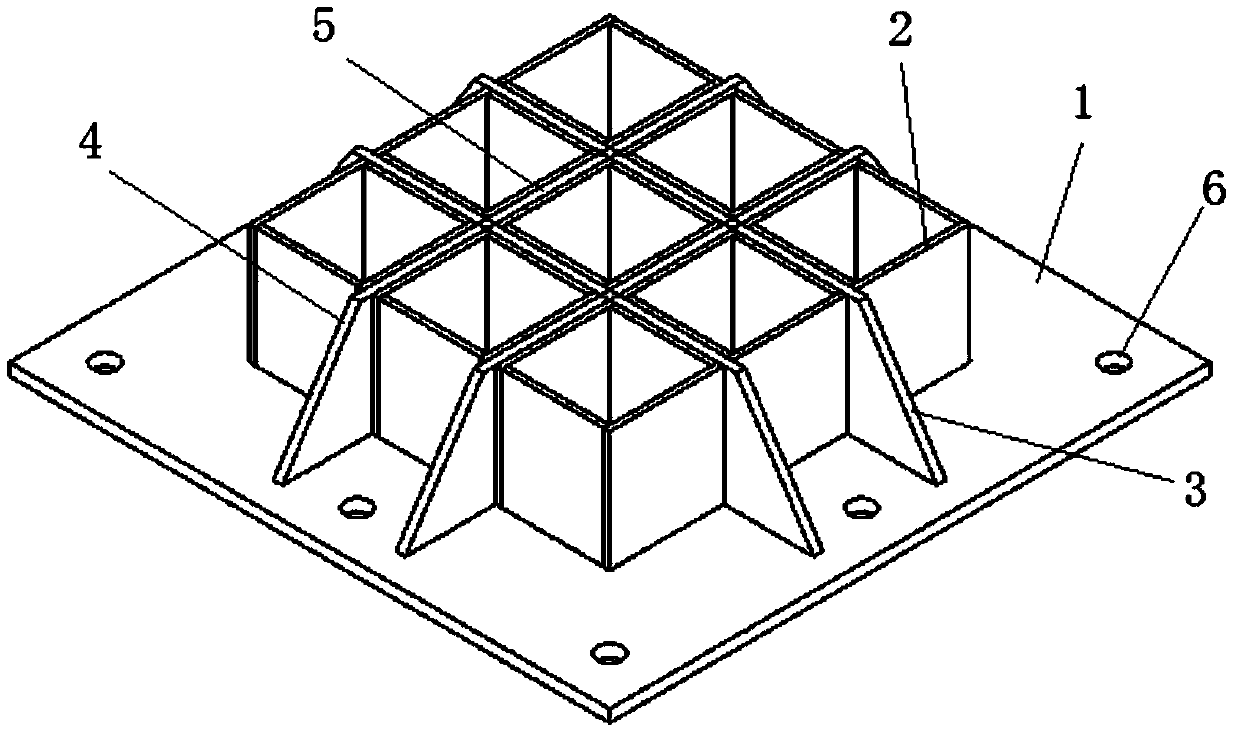

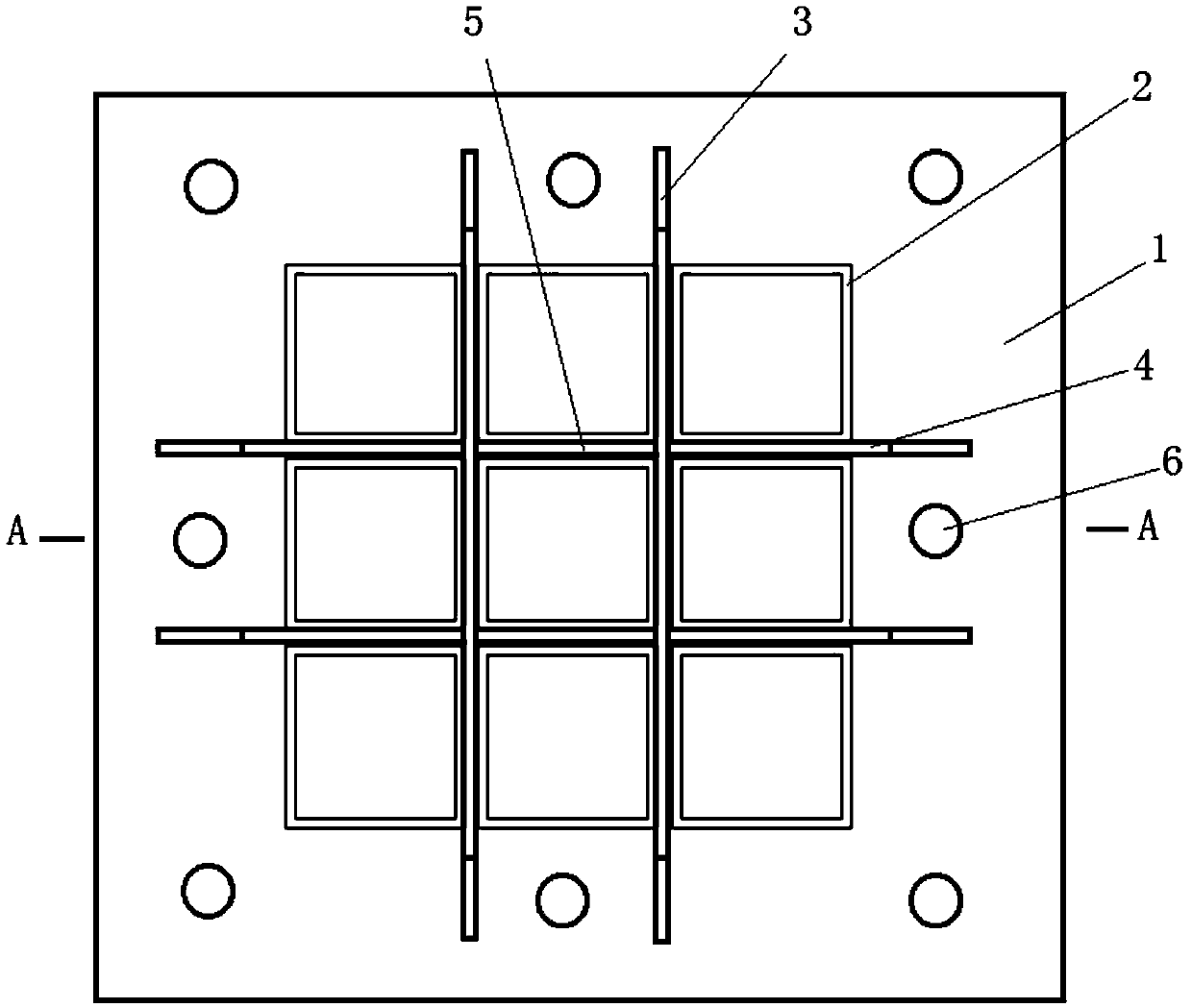

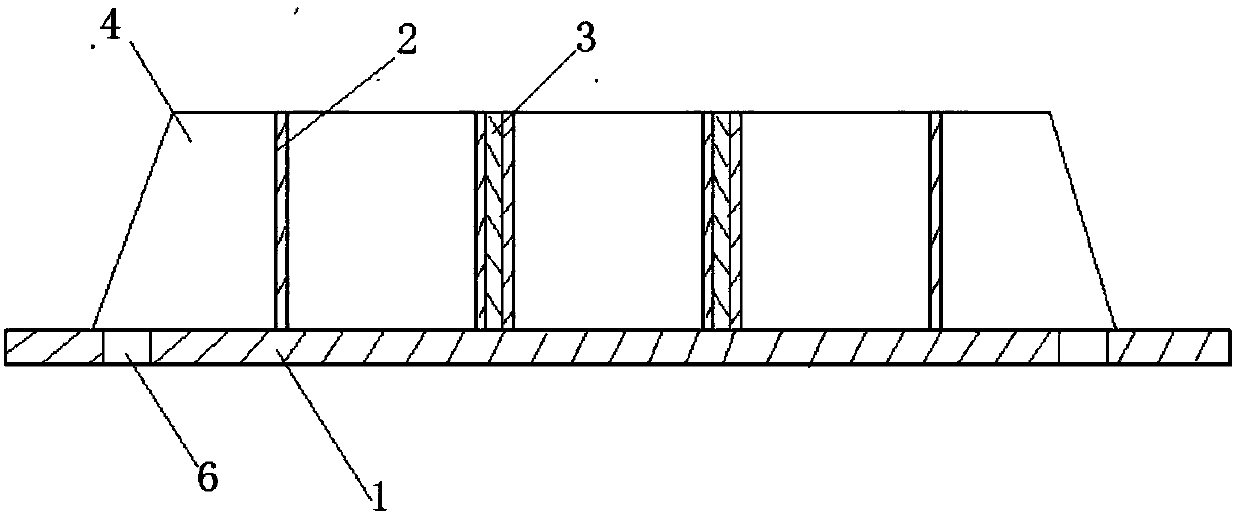

[0011] Such as figure 1 , figure 2 , image 3 The exposed column foot node components for installing steel columns as shown include a square steel base plate 1, a group of upright square steel pipes 2 arranged in a lattice shape neatly arranged in the middle of the steel base plate, and are respectively inserted and inserted in the corresponding A group of isosceles trapezoidal stiffeners between adjacent rows of steel pipes with the lower bottom placed on the steel floor 3, longitudinally inserted between the adjacent square steel pipes of the front and rear two rows of square steel pipes and the lower bottom placed on the steel floor A set of right-angled trapezoidal stiffening plates 4, a set of rectangular stiffening plates 5 inserted longitudinally between the adjacent square steel pipes of the square steel pipes in the middle row and placed on the steel base plate, uniformly distributed around the steel base plate Anchor bolt holes 6 for installing anchor bolts. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com