Conversion mechanism for spring pressure gauge

A conversion mechanism and spring pressure technology, which is applied in the measurement of fluid pressure, the measurement of elastic deformation force through the measurement gauge, and the measurement of force, can solve the problems of complex structure of the conversion mechanism, cumbersome assembly operations, and unfavorable assembly efficiency. Small size, convenient assembly and operation, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, concrete structure among the present invention is described:

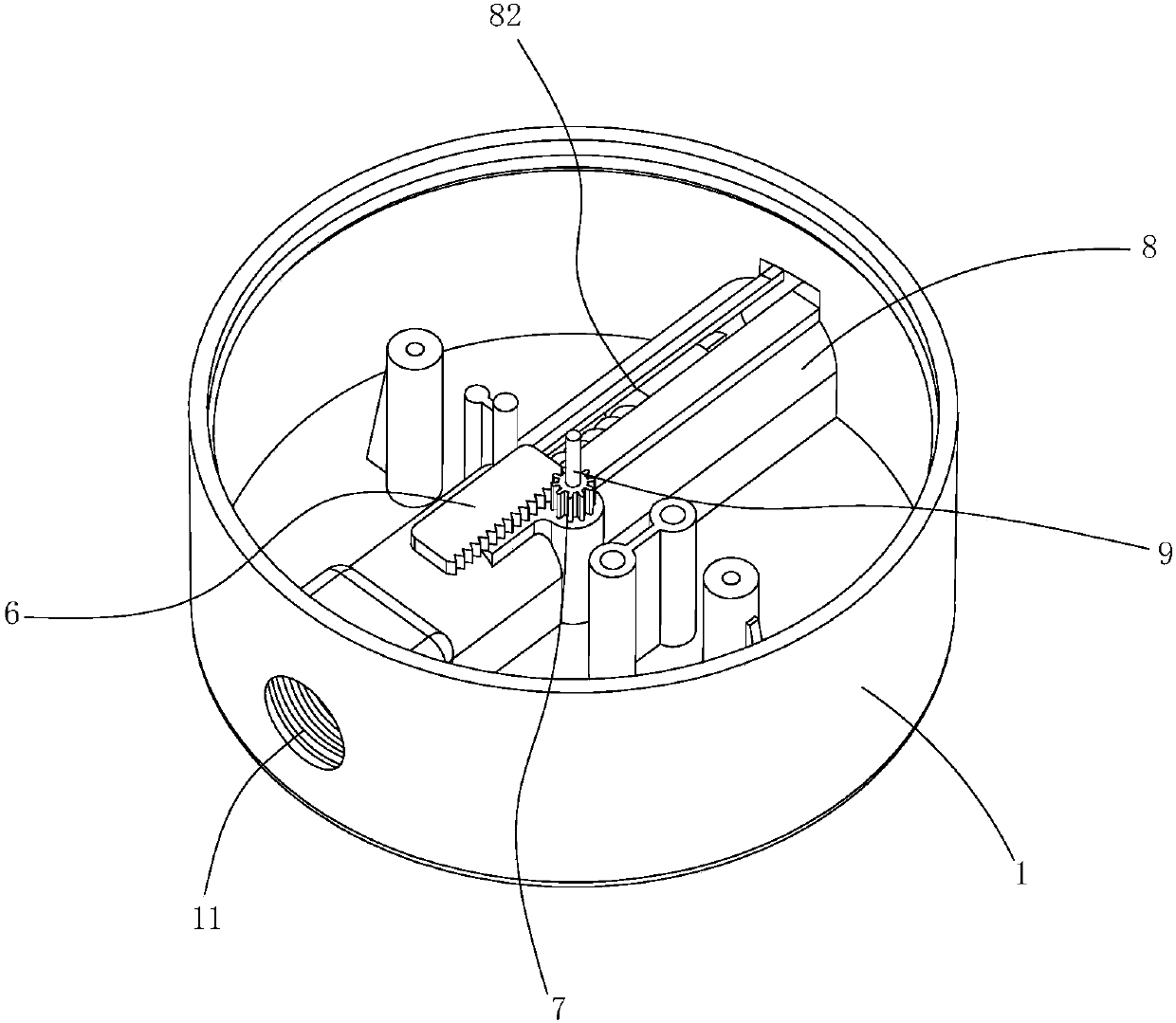

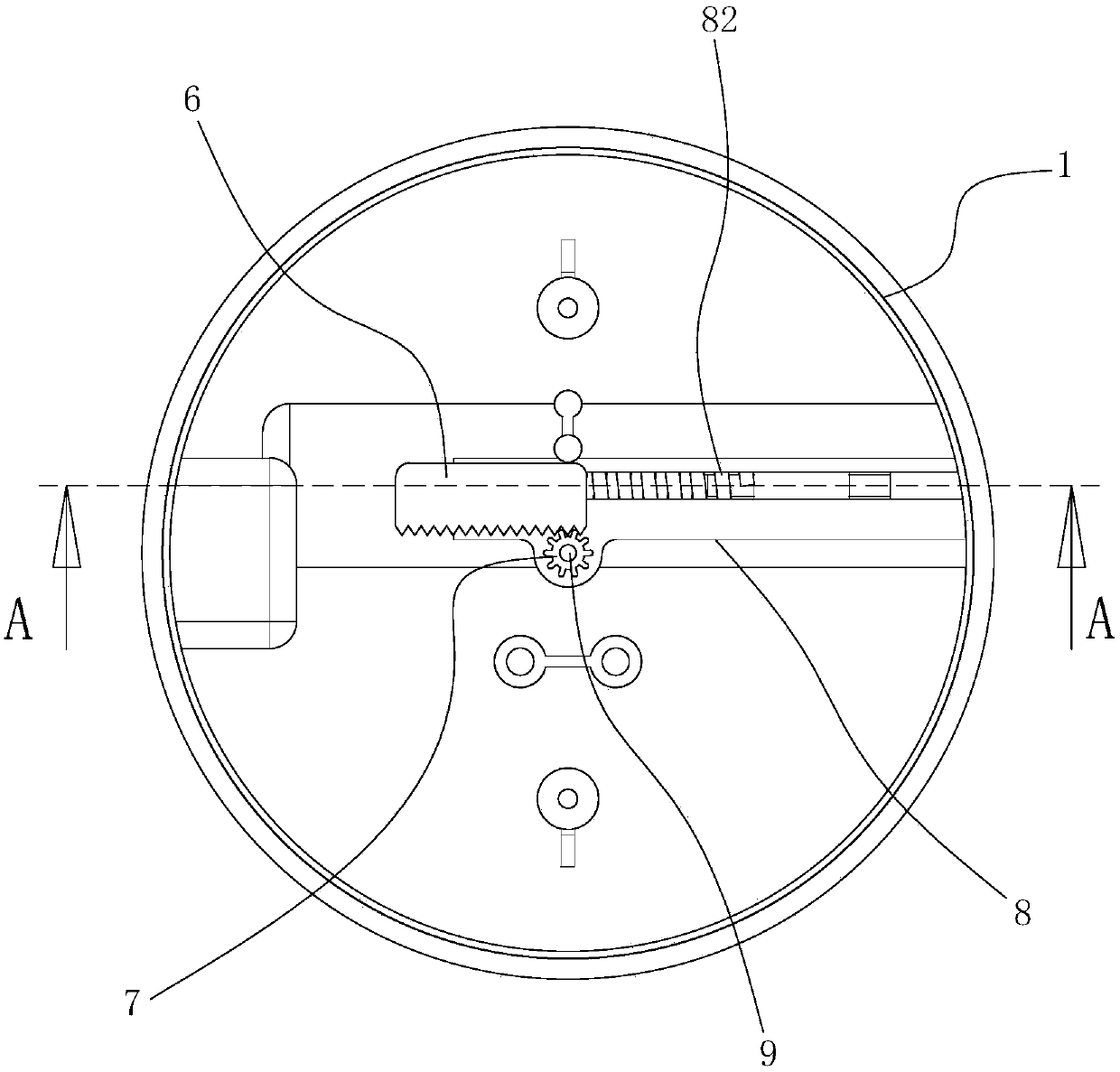

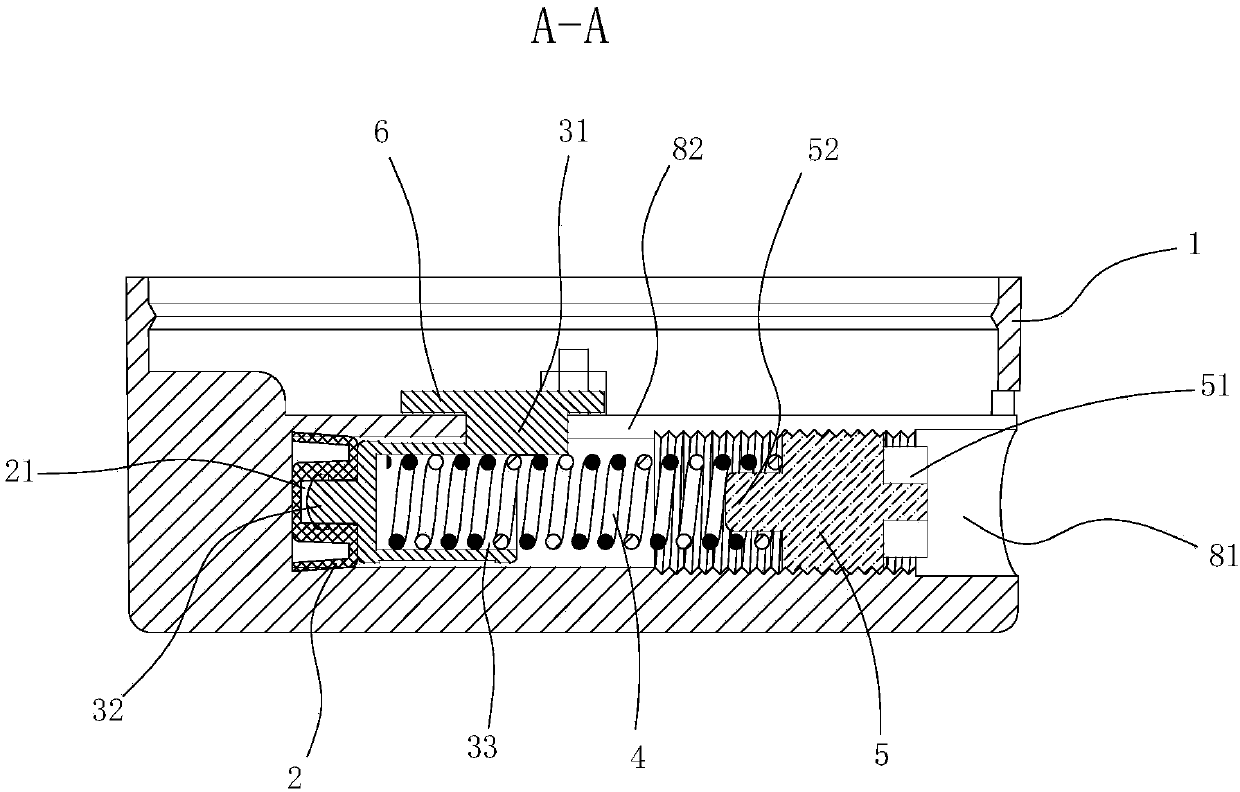

[0021] A conversion mechanism for a spring pressure gauge, such as Figure 1 to Figure 6 As shown, it includes a watch case 1, a seal 2, a piston block 3, a spring 4, a limit member 5, a transmission rack 6 and a transmission gear 7, and the inner bottom of the watch case 1 is integrally formed with a tubular shell arranged horizontally. body 8, an air port 11 is formed on the side wall of the watch case 1, and an air inlet passage 10 connecting the inner cavity of the tubular case 8 and the air port 11 is formed at one end of the tubular case 8 , the other end of the tubular housing 8, that is, the side wall of the watch case 1, is provided with an opening 81, and the sealing member 2, the piston block 3, the spring 4 and the limiting member 5 are formed by The openings 81 are sequentially loaded into the tubular housing 8, the sealing member 2 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com