Condensed water discharge performance testing experiment table for micro-channel evaporator

A technology for testing experiments and evaporators, which is used in the testing of machines/structural components, instruments, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

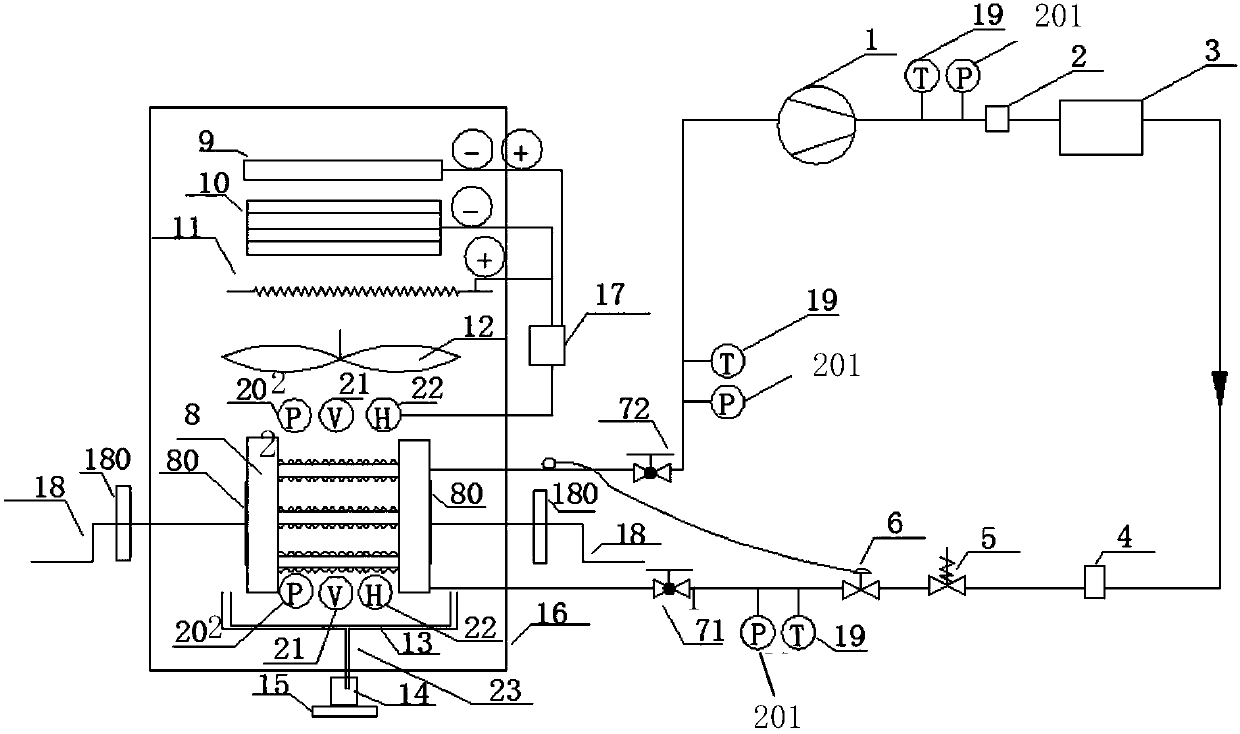

[0040] see figure 1 , the present invention provides a condensed water discharge performance test bench for a microchannel evaporator, comprising a compressor 1, the refrigerant outlet at the right end of the compressor 1 passes through an oil separator 2 and the refrigerant inlet at the left end of the condenser 3 connected (through pipelines);

[0041] The refrigerant outlet at the right end of the condenser 3 communicates with the refrigerant inlet at the right end of a thermal expansion valve 6 through a mass flow meter 4 and a solenoid valve 5 (through a pipeline);

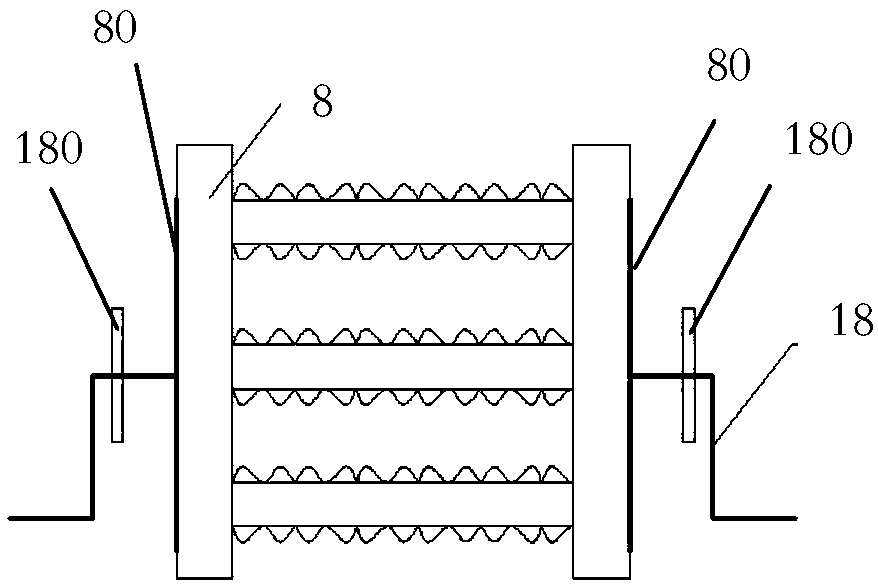

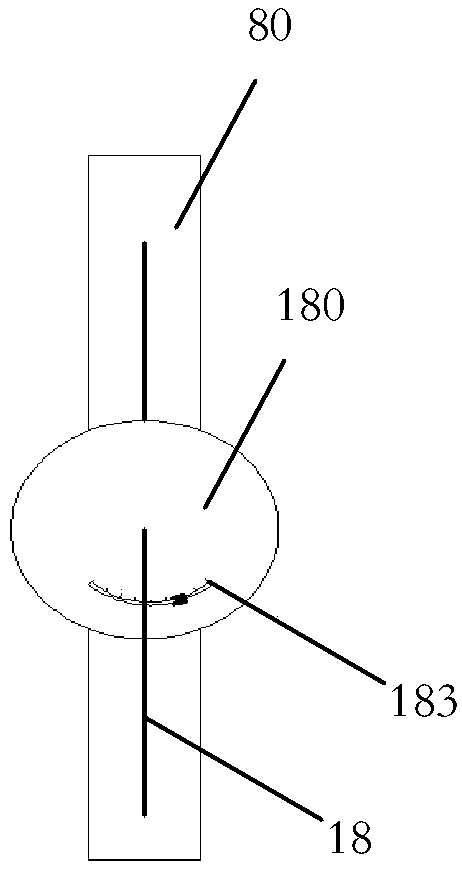

[0042] The refrigerant outlet at the left end of the thermal expansion valve 6 communicates with the refrigerant inlet at the lower right end of a microchannel evaporator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com