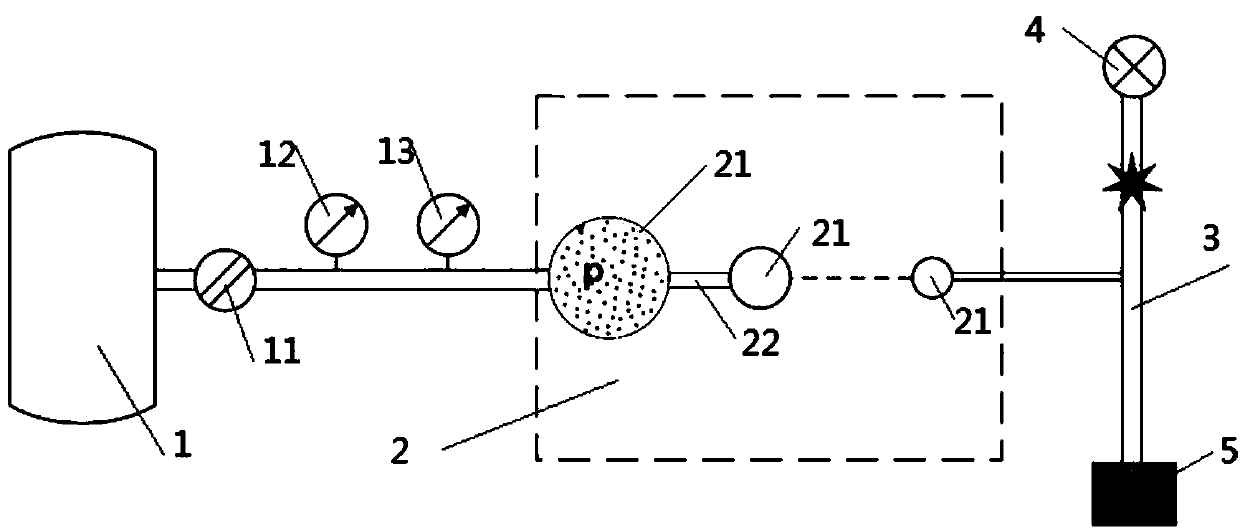

Experiment apparatus and experiment method for measuring fine-particle-containing two-phase flow in thin pipe network

An experimental device, fine particle technology, applied in measurement devices, particle and sedimentation analysis, particle size analysis, etc., can solve problems such as lack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

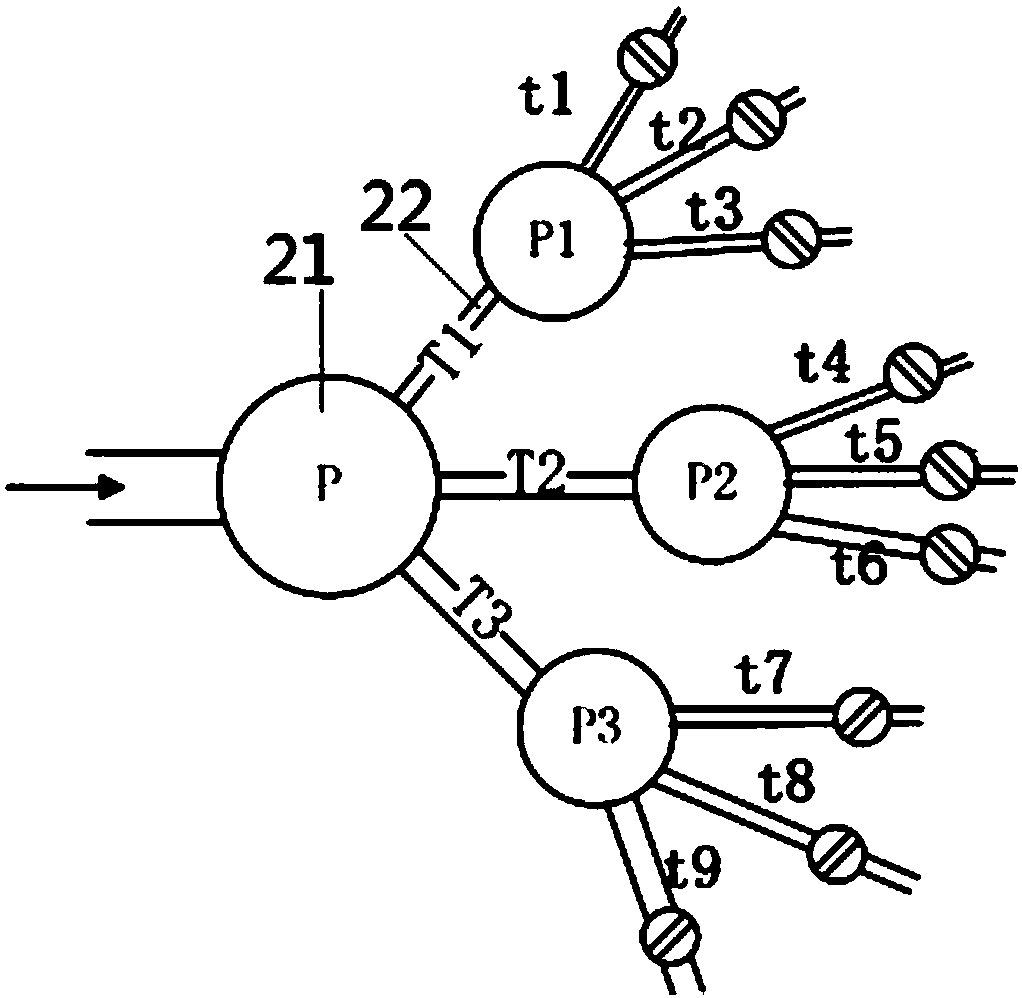

[0046] 1) Fill the tracer and fine particles of different particle sizes and colors into the four balls at the head end of the thin tube network module, and fill the containers P, P1, P2, and P3 with fine sand;

[0047] 2) Set the inlet pressure of the liquid injection to 0.5MPa, and the outlet is connected to the atmosphere, and inject pure water to carry out the fine particle migration experiment;

[0048] 3) Turn on the gas supply and liquid supply module, and pure water passes through the thin tube network module;

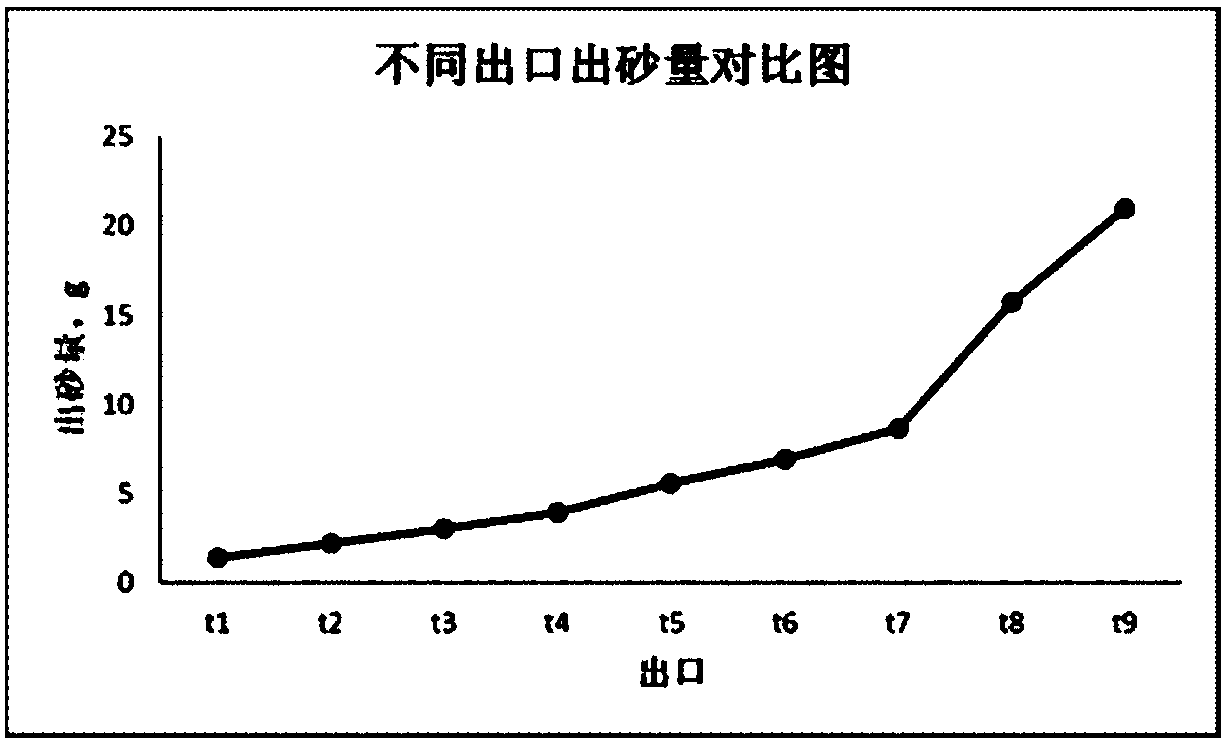

[0049] 4) Measure the pressure 0.54MPa and the flow rate 0.28cm of the head end inlet of the thin tube network module 3 / s, using a high-speed camera to measure the migration speed of fine particles and fluids. The tracer particle velocities in T1, T2, and T3 are 0.3cm / s, 0.8cm / s, and 0.7cm / s respectively. The particle volume measurement module measures the fluid volume and the body weight of the fine particles flowing out through the thin tube network module ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com